Glass fiber warping machine

A glass fiber and warping machine technology, applied in the field of warping machines, can solve the problems of low tension and inability to weave on a loom, and achieve the effect of improving the tension of the sheet yarn and achieving a good weaving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

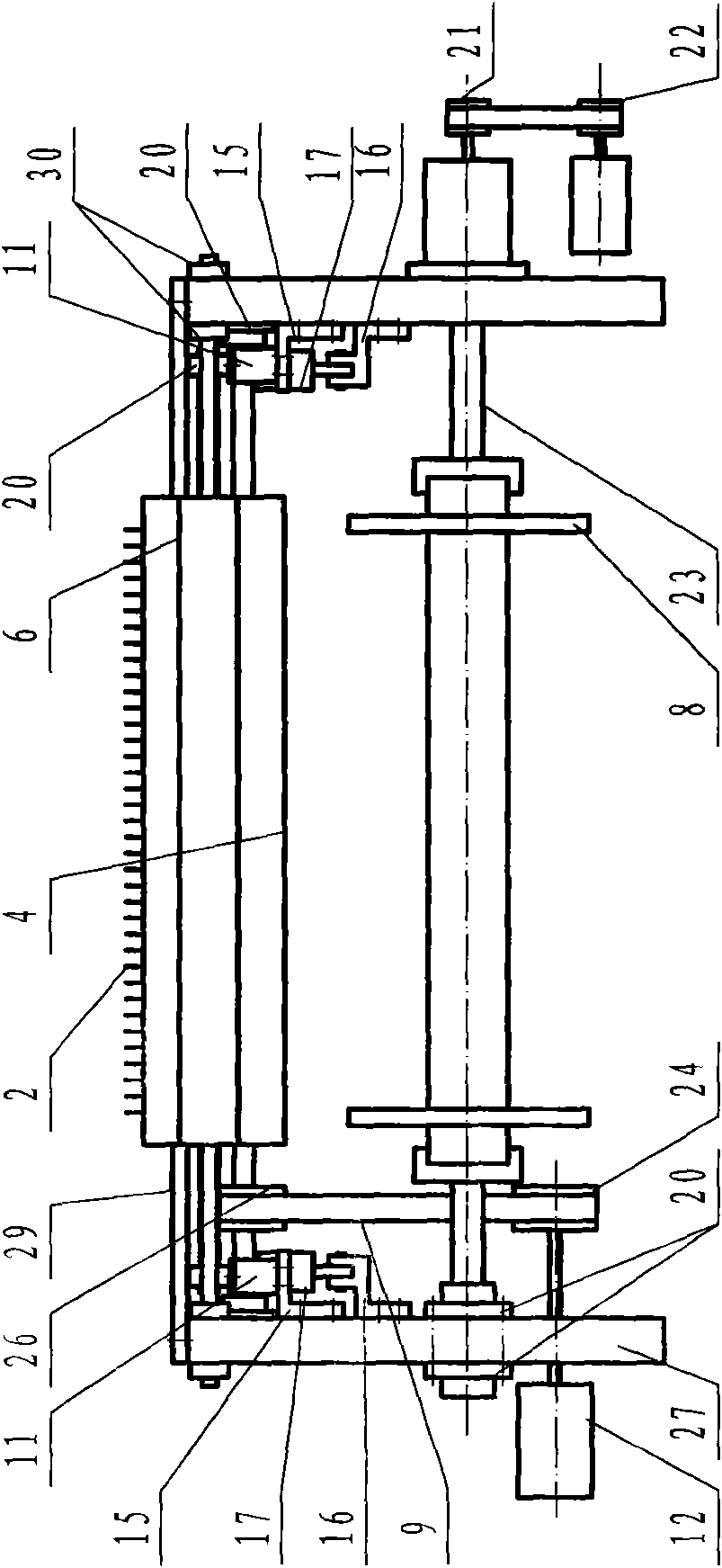

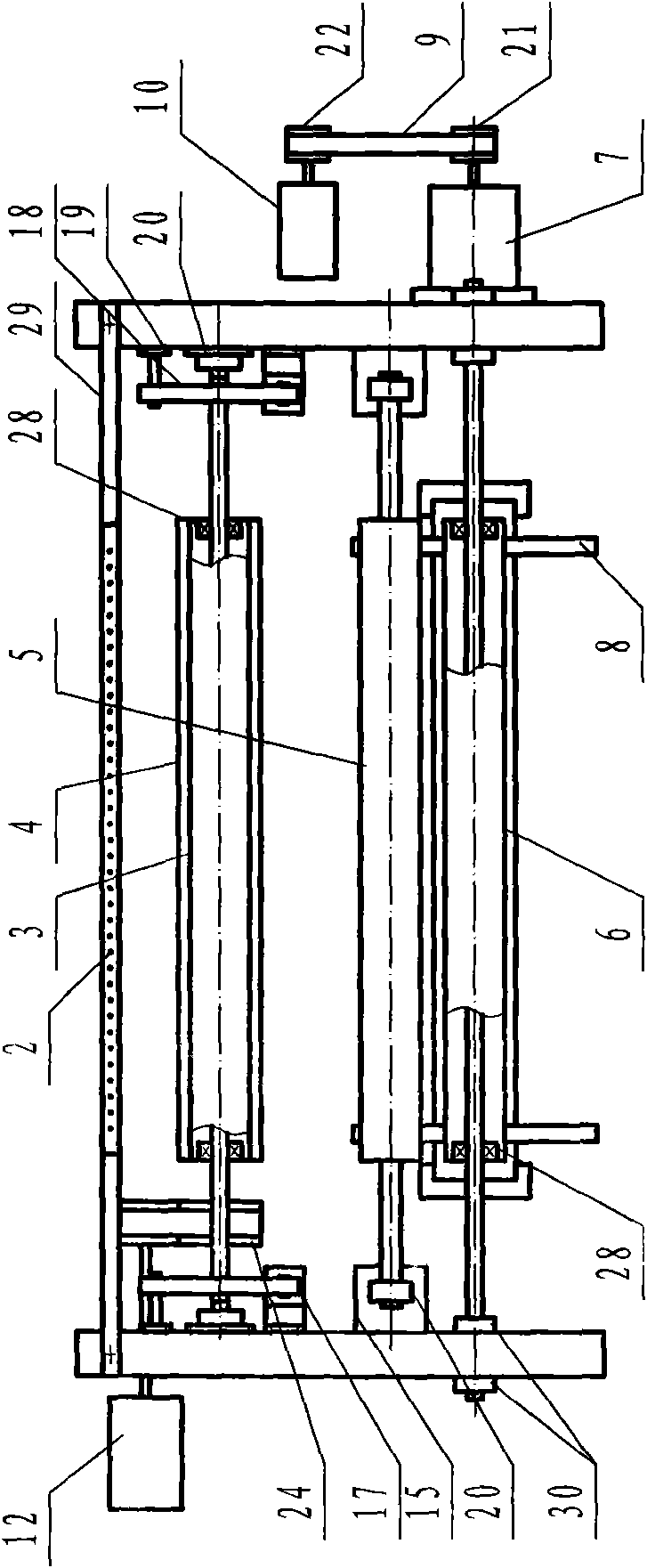

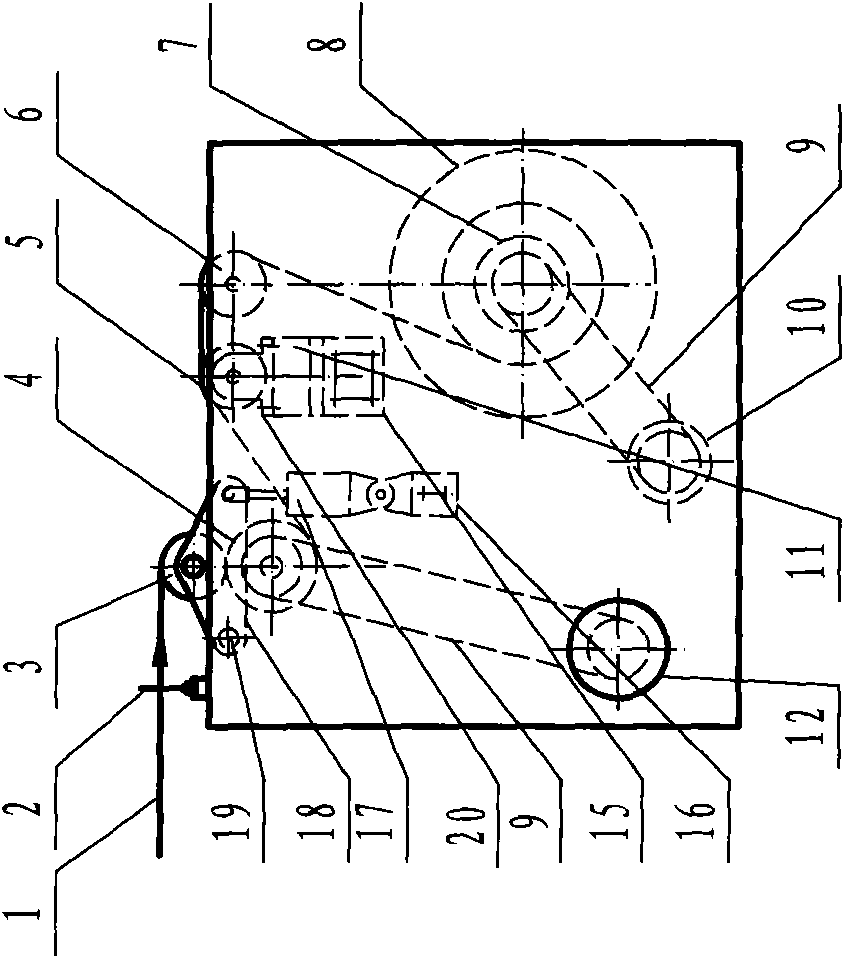

[0014] Describe the present invention in detail below in conjunction with accompanying drawing:

[0015] Such as Figure 1-3 Shown, this machine is constituted frame by left and right wall board 27, is equipped with steel sley 29 and steel reed 2 on the frame rear top surface, and the two ends of weaving shaft 8 are arranged in the middle and lower part of frame; The motor 10 is arranged on the right wallboard 27, and the power output shaft of the winding motor 10 drives the transmission shaft 23 to drive the weaving shaft 8 through the pulley 22, the wheel belt 9, the pulley 21 and the reducer 7, and the left end of the weaving shaft 8 is driven. Axle 23 is installed on the two belt seat bearings 20 on the left wallboard 27; Be equipped with guide roller 6 on the top frame of weaving beam 8, guide roller 6 plays the guiding effect to yarn, guide roller 6. The bearings 28 in the inner holes at both ends are rotatably fitted on the guide roller mandrel, and the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com