Weft-guiding mechanism for multi-layer cylindrical weaving machine

A technology of weft insertion mechanism and multi-layer cylinder is applied in the field of improving weft insertion efficiency and weaving effect. , to avoid the effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

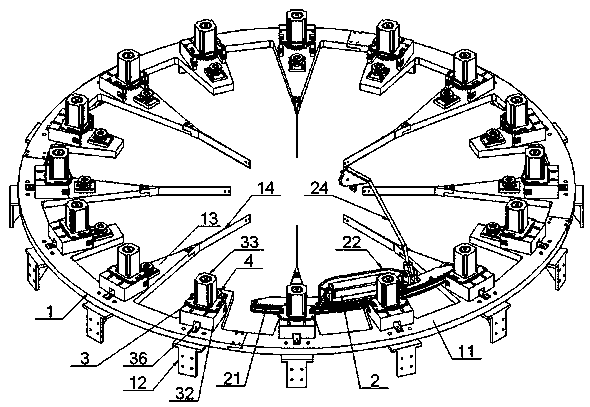

[0042] see figure 1 , a weft insertion mechanism of a multi-layer cylindrical loom, comprising a weft insertion fixing plate 1 and a weft insertion shuttle 2, the weft insertion fixing plate 1 is a ring structure, and the weft insertion fixing plate 1 is uniformly arranged along its circumferential direction 16 sets of transmission devices 3 and 16 shuttle limit wheels 4; the weft insertion fixed plate 1 is spliced by four arc-shaped plates 11; the weft insertion fixed plate 1 is evenly arranged with 16 connecting Seat 12; 16 mounting plates 13 are evenly arranged on the inner peripheral surface of the weft insertion fixing plate 1, and a partition plate 14 is connected to one mounting plate 13 in every adjacent two mounting plates 13, and the transmission device 3 , The shuttle limit wheel 4 is all arranged on the mounting plate 13.

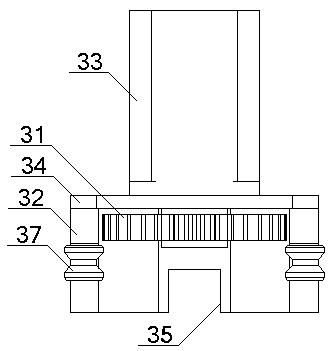

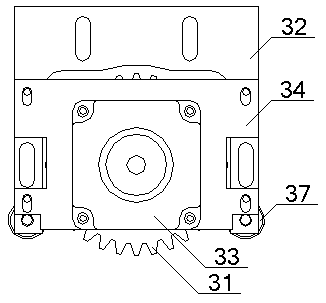

[0043] see Figure 1 to Figure 3 , the transmission device 3 includes a fixed seat 32 and a stepping motor 33, the stepping motor 33 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com