Opening device for forming multilayer 2.5D fabric

A technology of shedding device and fabric, which is applied in the direction of cam shedding mechanism, textile, loom, etc. It can solve the problems of inability to move height and position, difficulty in automatic production, inability to realize automatic weft insertion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

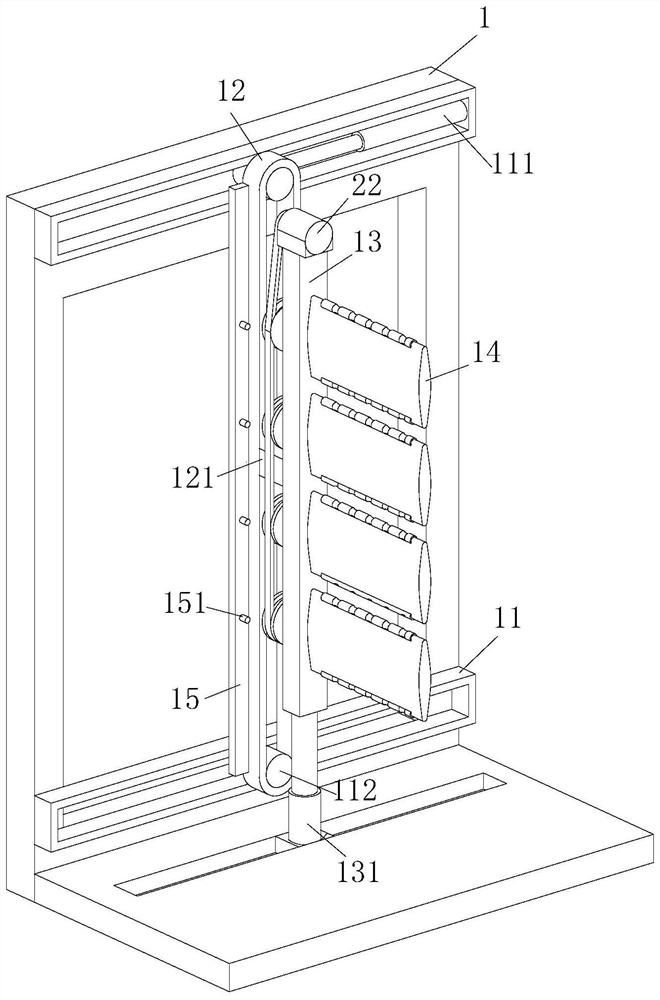

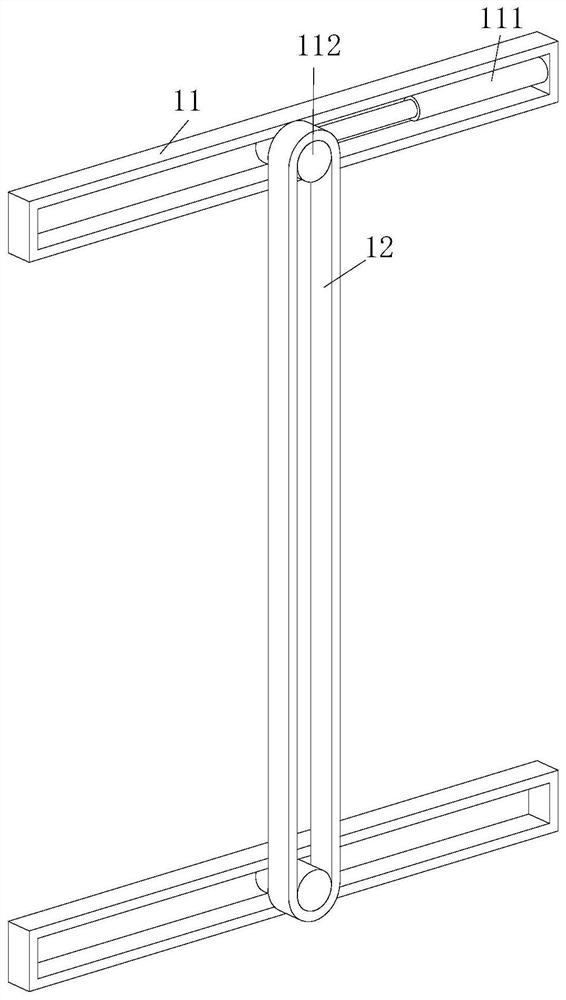

[0034] A multi-layer 2.5D fabric forming opening device, including a bracket 1, the upper and lower ends of the side wall of the bracket 1 are evenly connected with a No. No. 1 slide rail 12 is slidably connected with No. 1 slide rail 12, and No. 1 electric telescopic rod 111 is fixedly connected in the No. 1 slide rail 11, and No. 1 electric telescopic rod 111 is connected with No. Fixed;

[0035] The inside of the No. 2 slide rail 12 is slidably connected to a No. 1 block 13 through the No. 2 slide block 121. There is a gap between the No. 1 block 13 and the No. 2 slide rail 12. The lower end of the No. 1 block 13 is fixedly connected with a No. 2 electric telescopic rod 131, said No. 2 electric telescopic rod 131 is slidably connected to the lower end of support 1;

[0036] A No. 1 column 132 is evenly arranged on the side of the No. 1 block 13 away from the No. 2 slide rail 12, and one end of the No. 1 post 132 passes through the No. 1 block 13 and is rotatably connected ...

Embodiment 2

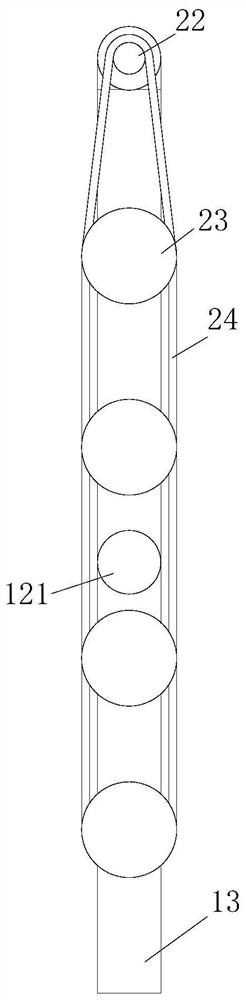

[0053] The difference between the first embodiment and the second embodiment is that the transmission unit 2 includes a motor 22, a shaft pulley 23 and a belt 24; the motor 22 is fixedly connected to the upper end of the second block 14, each of the first The end of the column 132 away from the second block 14 is fixedly connected with a shaft pulley 23, and the motor 22 and the shaft pulley 23 are connected by a belt 24;

[0054] During use, the transmission unit 2 includes a motor 22, a shaft pulley 23 and a belt 24, the motor 22 is fixedly connected to the upper end of the No. 2 block 14, and the end of the No. 1 column 132 away from the No. 2 block 14 is fixedly connected to the shaft pulley. 23, and connect the motor 22 and the shaft pulley 23 through a belt 24, and by controlling the rotation angle of the motor 22, the motor 22 can control the rotation angle of the shaft pulley 23 through the belt 24, thereby realizing the control of the rotation of the first column 132 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com