Pulp coolant for cotton spinning and wool spinning fibers

A chemical fiber and cotton spinning technology, applied in the field of high-efficiency cold sizing sizing, can solve the problems of reducing the affinity of polymer and wool fiber macromolecules, poor wool wettability, and coarse wool fiber elasticity, etc., and achieve excellent penetration and antistatic properties. , prolong the cleaning cycle, improve the effect of weaving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

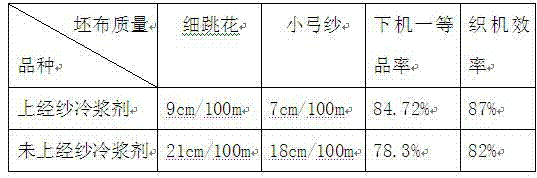

Examples

Embodiment 1

[0048] Example 1: Preparation of cold sizing agent for cotton spinning wool spinning chemical fiber

[0049] 8kg emulsifier TX-40, 8kg emulsifier EL-40, 5kg fatty alcohol polyoxyethylene ether, 9.5kg coconut oil fatty acid diethanolamide, 4.5kgPEG-6000, 12kg methyl acrylate, 10.2kg acrylamide, 4.5kg acrylic acid , 15g of ammonium persulfate, 15g of potassium persulfate and 51kg of water were mixed and stirred, heated up to 65°C, kept for 3 hours, then cooled to 30°C, and 2kg of diethanolamine was added to adjust the pH value to 6-7 to obtain the target product.

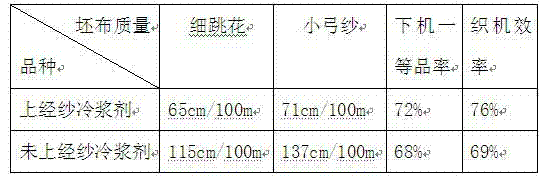

Embodiment 2

[0050] Example 2: Preparation of cold sizing agent for cotton spinning wool spinning chemical fiber

[0051] 7.5kg emulsifier TX-40, 7.5kg emulsifier EL-40, 4.5kg fatty alcohol polyoxyethylene ether, 9kg coconut oil fatty acid diethanolamide, 4kgPEG-6000, 11.5kg methyl acrylate, 10kg acrylamide, 4kg acrylic acid , 10g of ammonium persulfate, 10g of potassium persulfate and 50kg of water were mixed and stirred, heated to 65°C, kept for 3 hours, then cooled to 30°C, and 1.5kg of diethanolamine was added to adjust the pH value to 6-7 to obtain the target product.

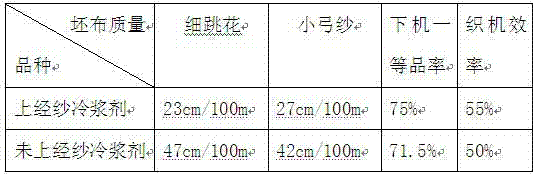

Embodiment 3

[0052] Example 3 : Preparation of cold slurry agent for cotton spinning wool spinning chemical fiber

[0053] 8.5kg emulsifier TX-40, 8.5g emulsifier EL-40, 5.5kg fatty alcohol polyoxyethylene ether, 10kg coconut oil fatty acid diethanolamide, 5kgPEG-6000, 12.5kg methyl acrylate and 10.5kg acrylamide, 5kg Acrylic acid, 20g of ammonium persulfate, 20g of potassium persulfate and 52kg of water were mixed and stirred, heated to 65°C, kept for 3 hours, then cooled to 30°C, and 2.5kg of diethanolamine was added to adjust the pH value to 6-7 to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com