Finishing method of multifunctional textile

A textile and multi-functional technology, applied in the direction of textiles and papermaking, fiber treatment, liquid repellent fibers, etc., can solve the problems of poor hand feeling, large color difference of textiles, single type of waterproofing agent, etc., to improve the process and technology, source Wide range of effects with simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

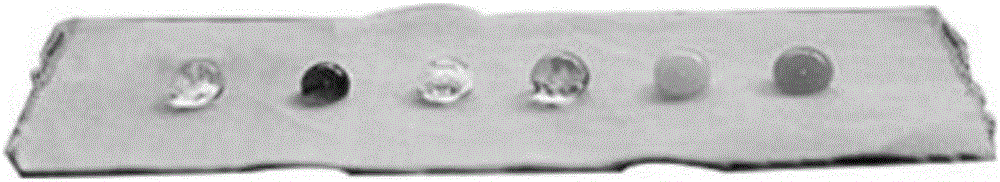

Image

Examples

Embodiment 1

[0036] Embodiment 1: multifunctional textile finishing method A

[0037] Soak about 0.05g cotton cloth in 10wt% TDI acetone solution for 1 hour, spray the acetone solution of 10wt% hydroxyfluoroether and 0.01-10wt% organotin on one side of the soaked cotton cloth, then spray 10wt% sodium hydroxysulfonate and 0.01-10 wt% organotin solution in acetone, the sprayed textiles are pre-baked in an oven at 90°C for 30 minutes, and then baked at 120°C for 6 hours to obtain cotton fabric sample A after method A finishing.

Embodiment 2

[0038] Embodiment 2: multifunctional textile finishing method B

[0039] Soak about 0.05g of cotton cloth in 10wt% MDI ethyl acetate solution for 1 hour, spray 10wt% ethyl acetate of hydroxyfluoroether and 1wt% organotin on one side of the soaked cotton cloth, and then spray 10wt% sodium hydroxysulfonate on the other side and 1 wt% ethyl acetate solution of organotin, the sprayed textiles were pre-baked in an oven at 90°C for 30 minutes, and then baked at 120°C for 6 hours to obtain cotton fabric sample B after method B finishing.

Embodiment 3

[0040] Embodiment 3: multifunctional textile finishing method C

[0041] Soak about 0.05g cotton cloth in 10wt% HDI ethylene glycol monobutyl ether solution for 1 hour, spray 10wt% hydroxyfluoroether and 0.01-10wt% organic bismuth ethylene glycol monobutyl ether on one side of the soaked cotton cloth, and then apply One side is sprayed with ethylene glycol monobutyl ether solution of 10wt% sodium hydroxysulfonate and 0.01-10wt% organic bismuth, and the sprayed textiles are pre-baked in an oven at 90°C for 30 minutes, and then baked at 120°C for 6 hours to obtain method C finishing After cotton fabric sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com