Synthesizing and finishing method of environment-friendly fluoride-free hydrophobic coating liquid

A synthesis method and coating solution technology, applied in the direction of liquid-repelling fibers, fiber treatment, textiles and papermaking, etc., can solve problems such as difficult large-scale industrial production, easy fall-off of surface nanoparticles, and human health effects, etc., to achieve Good hydrophobicity and oil-water separation performance, wide applicability of raw materials, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

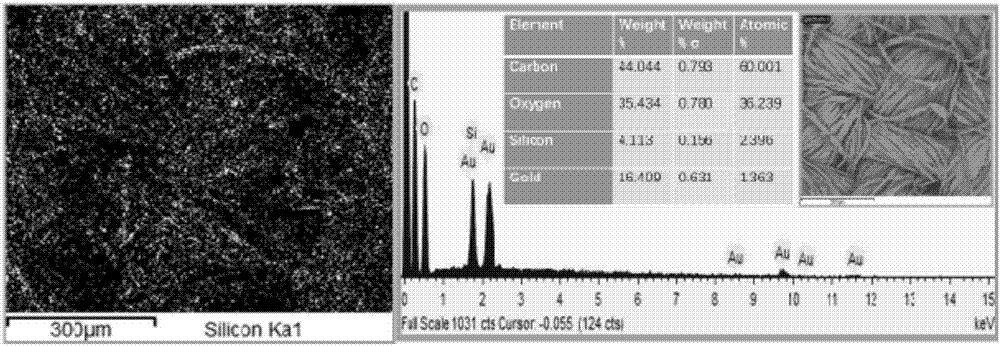

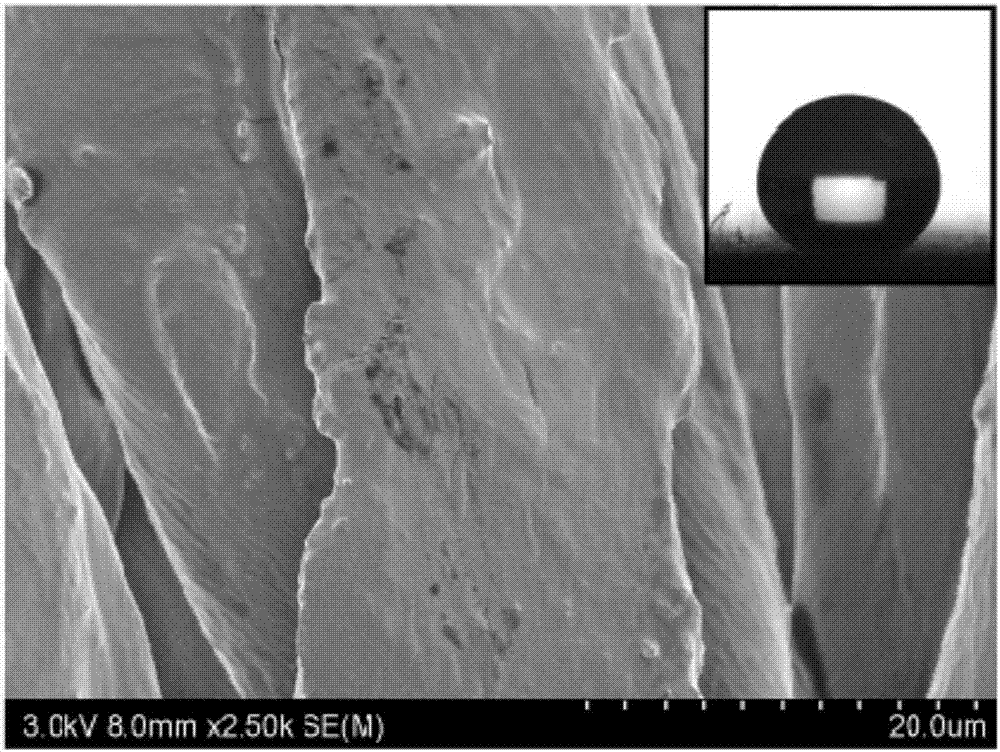

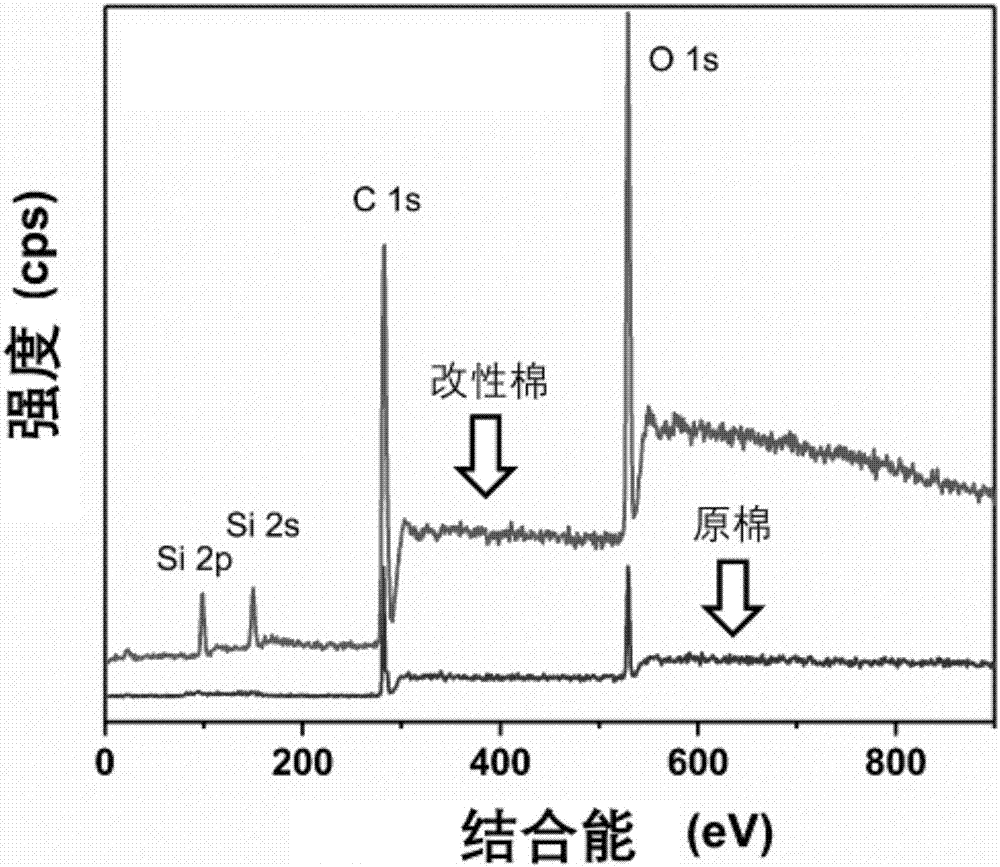

[0049] This implementation case shows the synthesis and finishing method of an environmentally friendly fluorine-free hydrophobic coating solution to prepare a superhydrophobic substrate according to the following steps:

[0050] Step 1: Prepare hydrophobic coating liquid emulsion

[0051] Dissolve 1g of PDMS in 30ml of THF and magnetically stir for 30 minutes to make it evenly dispersed, then drop 70ml of water into the above solution under ultrasonic vibration and continue ultrasonic oscillation for 30 minutes to prepare a stable hydrophobic coating liquid emulsion.

[0052] Step 2: Preparation of superhydrophobic substrate by dipping method

[0053] Soak the cotton fabric in the above-mentioned hydrophobic coating liquid emulsion for 30 minutes, take it out and dry it in an oven to obtain a superhydrophobic cotton fabric.

[0054] For the morphology and structure of the superhydrophobic cotton fabric (superhydrophobic substrate) prepared in this example, please refer to ...

Embodiment 2

[0056] This implementation case demonstrates an environmentally friendly fluorine-free hydrophobic coating solution and a synthesis and finishing method to prepare a superhydrophobic substrate according to the following steps:

[0057] Step 1: Prepare hydrophobic coating liquid emulsion

[0058] Dissolve 1g of PDMS in 10ml of THF and magnetically stir for 30 minutes to make it evenly dispersed, then drop 90ml of water into the above solution under ultrasonic vibration and continue ultrasonic oscillation for 30 minutes to prepare a stable hydrophobic coating liquid emulsion;

[0059] Step 2: Preparation of superhydrophobic substrate by dipping method

[0060] Soak the cotton fabric in the above-mentioned hydrophobic coating liquid emulsion for 60 minutes, take it out and dry it in an oven to obtain a superhydrophobic cotton fabric.

[0061] For the morphology and structure of the superhydrophobic cotton fabric (superhydrophobic substrate) prepared in this example, please refer...

Embodiment 3

[0063] This implementation case shows the synthesis and finishing method of an environmentally friendly fluorine-free hydrophobic coating solution to prepare a superhydrophobic substrate according to the following steps:

[0064] Step 1: Prepare hydrophobic coating liquid emulsion

[0065] Dissolve 1g of PDMS in 30ml of THF and stir magnetically for 30 minutes to make it evenly dispersed, then drop 70ml of water into the above solution under ultrasonic vibration and continue ultrasonic oscillation for 30 minutes to prepare a stable hydrophobic coating liquid emulsion;

[0066] Step 2: Preparation of superhydrophobic substrate by dipping method

[0067] Soak the colored garment in the above-mentioned hydrophobic coating liquid emulsion for 30 minutes, take it out, and dry it in an oven to obtain a superhydrophobic colored fabric.

[0068] For the morphology and structure of the superhydrophobic substrate prepared in this example, please refer to Image 6 , Image 6 It is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com