A method for accelerating the transformation of crystal form II to crystal form I by applying flow shear to isotactic polybutene-1 structure melt

A technology of isotactic polybutene and melt, which is applied in the field of polymer processing, can solve problems such as inability to obtain better application, impact on transparency and purity, increase time cost, etc., to shorten the crystal transformation time and shorten the time Cost, the effect of speeding up the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

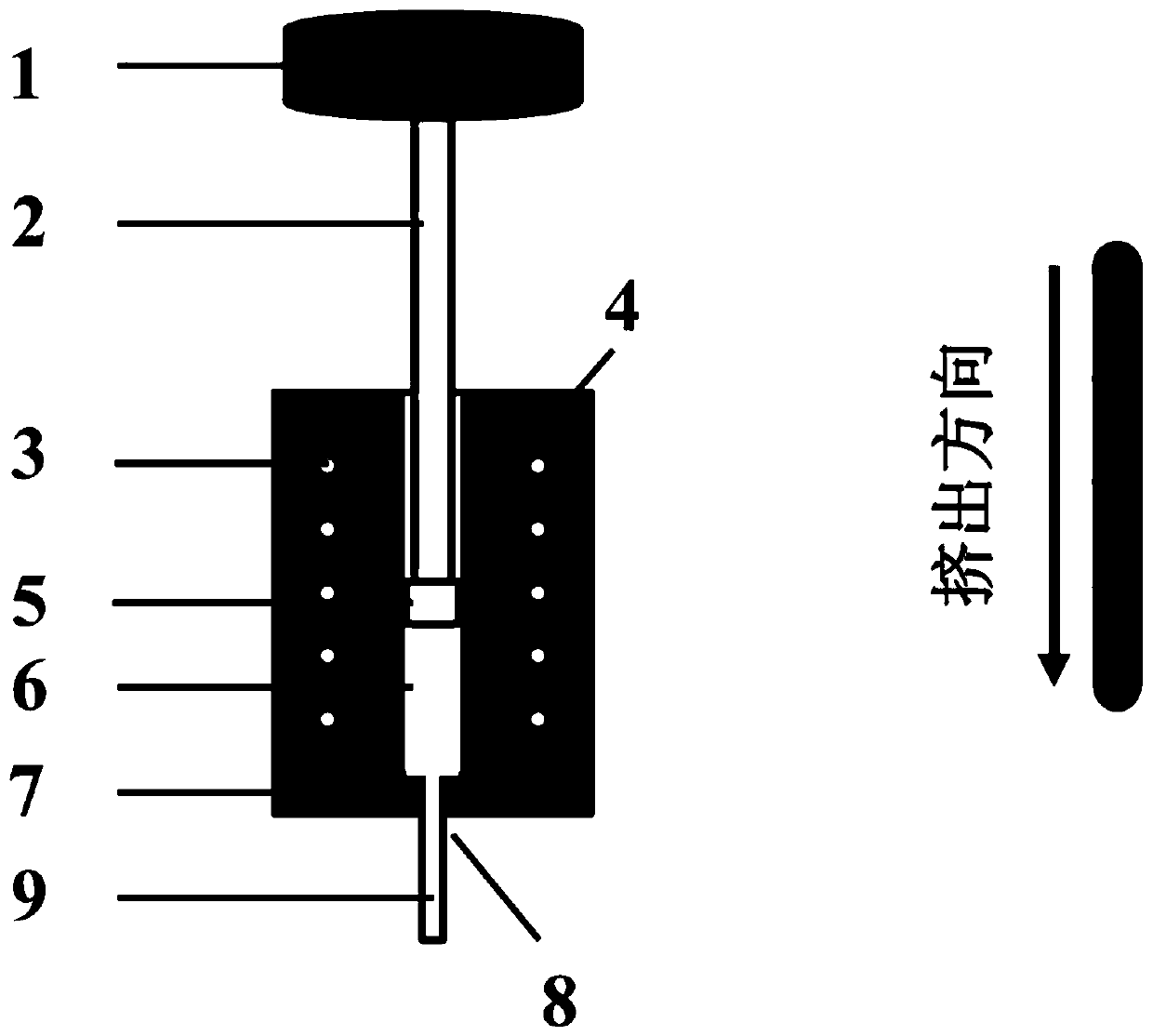

[0045] A method for accelerating the transformation of crystal form II to crystal form I by applying flow shear to isotactic polybutene-1 structure melt, the method comprising the following steps:

[0046] (1) Turn on the melt index meter, set the temperature program of the melt index meter, set its temperature to 180°C, set the holding time of this temperature to 10min; then set the second stage temperature to 131°C; temperature setting After completion, put the die and rod into the barrel for preheating;

[0047] (2) When the temperature of the melt index meter rises to 180°C, take out the die and material rod, and quickly add 3.5g of isotactic polybutene-1 particles into the barrel of the melt index meter through the hopper, and preheat for 2 minutes; After the heating is completed, a weight of 1.835kg is applied to the top of the material rod of the melt indexer, and the material rod gradually moves downward to discharge the air between the isotactic polybutene-1 materials...

Embodiment 4

[0054] A method for accelerating the transformation of crystal form II to crystal form I by applying flow shear to isotactic polybutene-1 structure melt, the method comprising the following steps:

[0055] (1) Turn on the melting index instrument, set the temperature program of the melting index instrument, set its temperature to 131°C, put the die and material rod into the barrel for preheating;

[0056] (2) When the temperature of the barrel of the melt index meter rises to 131°C, take out the preheated die and material rod; and weigh 3.5g of isotactic polybutene-1 particles into the barrel of the melt index meter through the hopper Preheat at 131°C for 2 minutes. After the preheating is completed, apply a weight of 1.835kg to the top of the rod of the melt indexer to discharge the air between the isotactic polybutene-1 materials. The rod gradually moves downward to discharge the air until The material can be observed from the die hole at the bottom of the melt index meter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com