Light gray dry-film conductive primer and preparation method thereof

A light gray, dry film technology, applied in the direction of conductive paint, coating, etc., can solve the problems of low resistivity, accidents, electrostatic coating voltage overload, etc., to improve utilization rate, save material cost, and improve paint utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is described in detail below. The embodiments of the present invention are only used to illustrate the technical solutions of the present invention without limitation. Although the present invention has been described in detail with reference to the preferred embodiments, those skilled in the art should understand that the technical solutions of the invention can be modified or equivalently replaced , without departing from the spirit and scope of the technical solution of the present invention, all of which shall be covered by the claims of the present invention.

[0021] If the reagents used in the present invention are not specified, industrial grades are used.

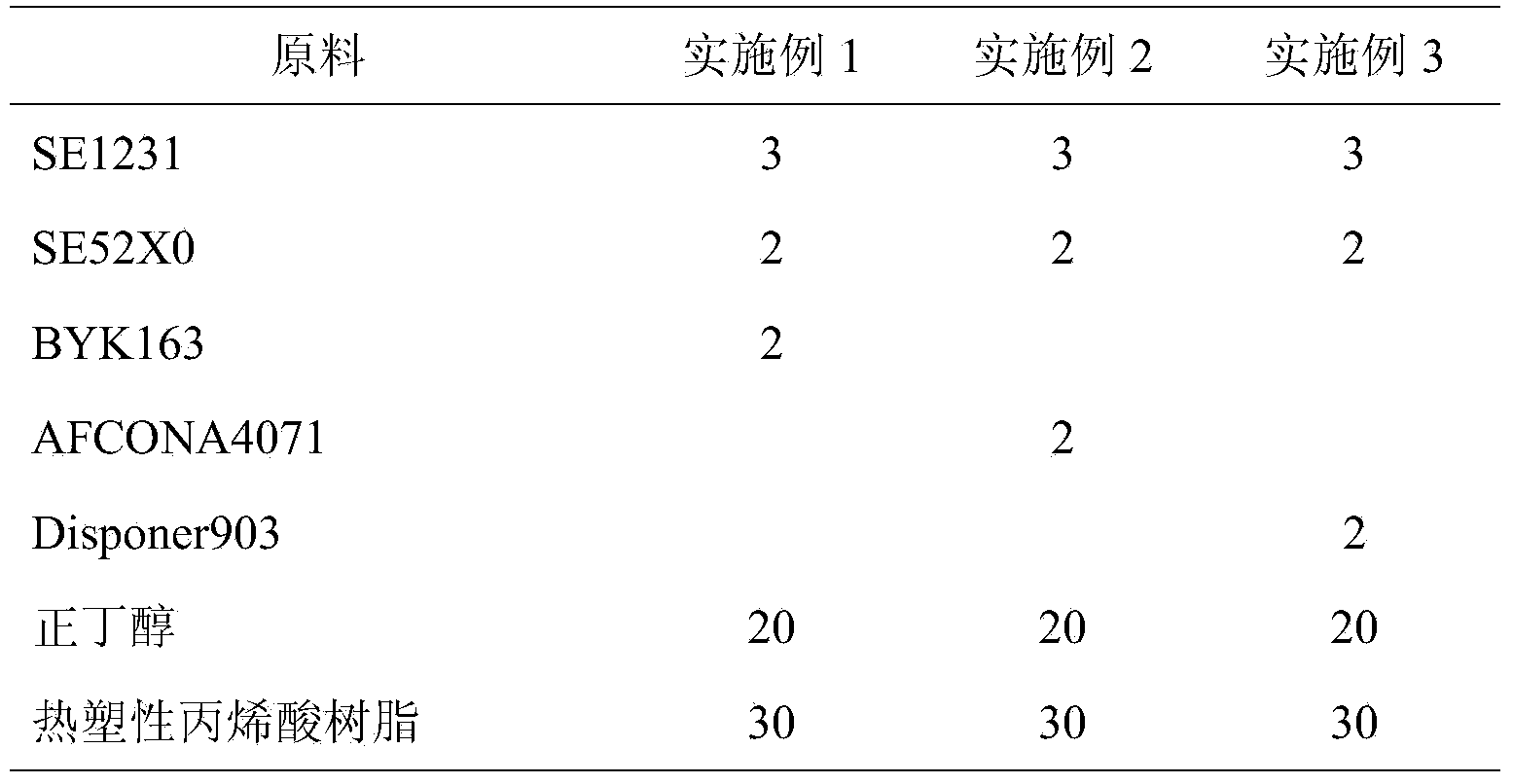

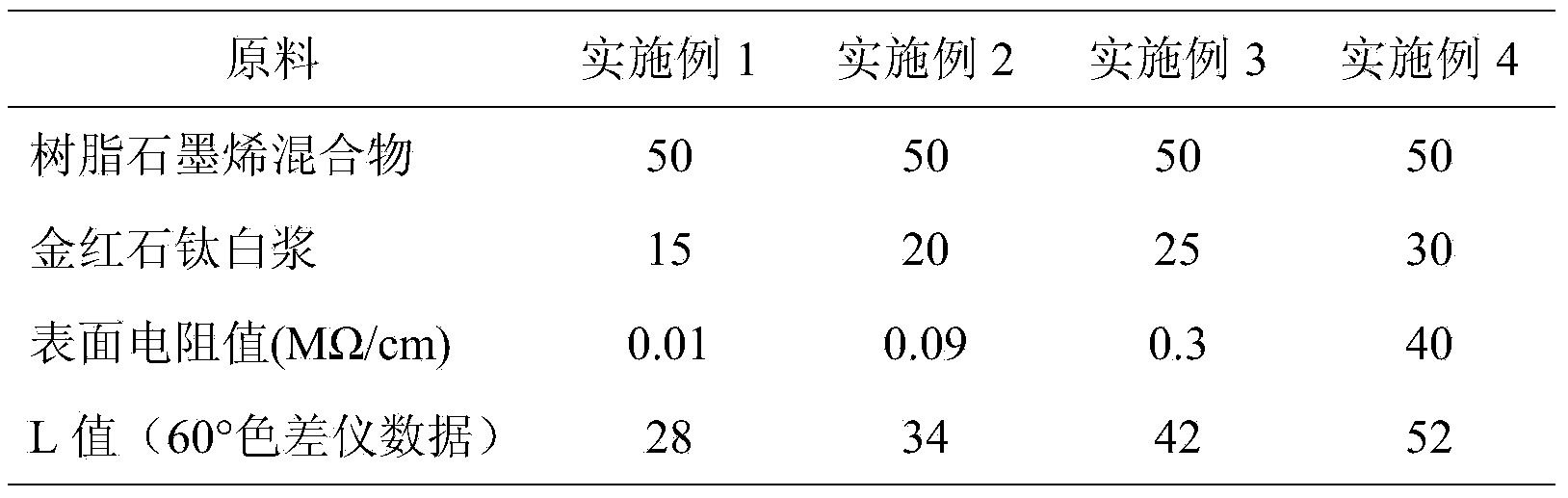

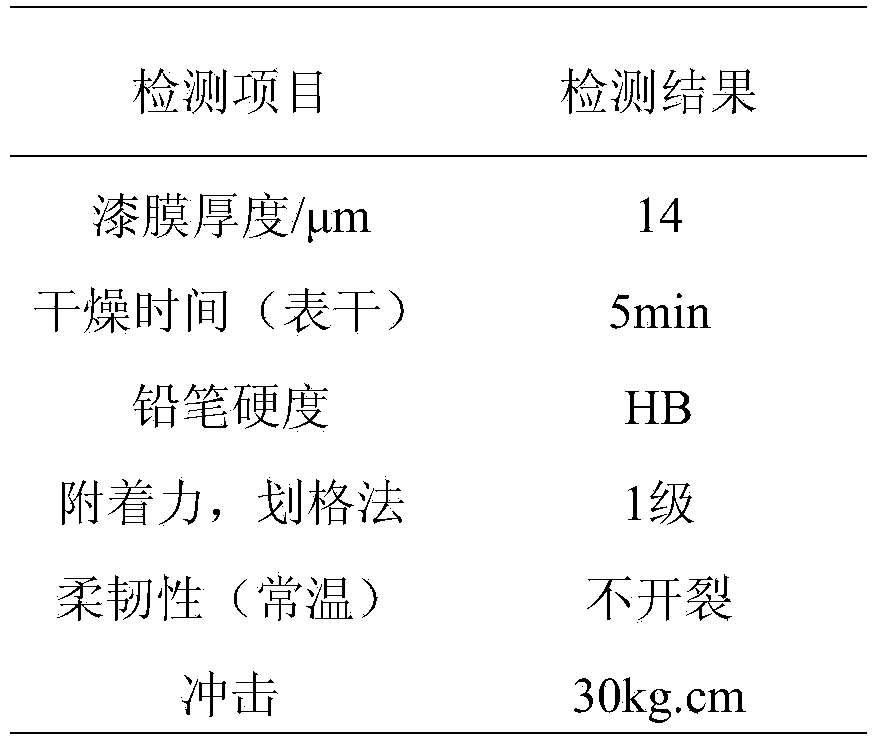

[0022] The light gray dry film conductive primer involved in the following embodiments of the present invention (see Table 1 and Table 2) are all prepared as follows:

[0023] Add 1-5 parts by weight of graphene into 20-30 parts by weight of solvent to soak, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com