Energy-saving and environment-friendly comprehensive processing device for wines and its technique

A comprehensive treatment and environmental protection technology, applied in the preparation of alcoholic beverages, can solve problems such as low temperature turbidity, and achieve the effects of reducing treatment costs, improving wine quality, and saving wine damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

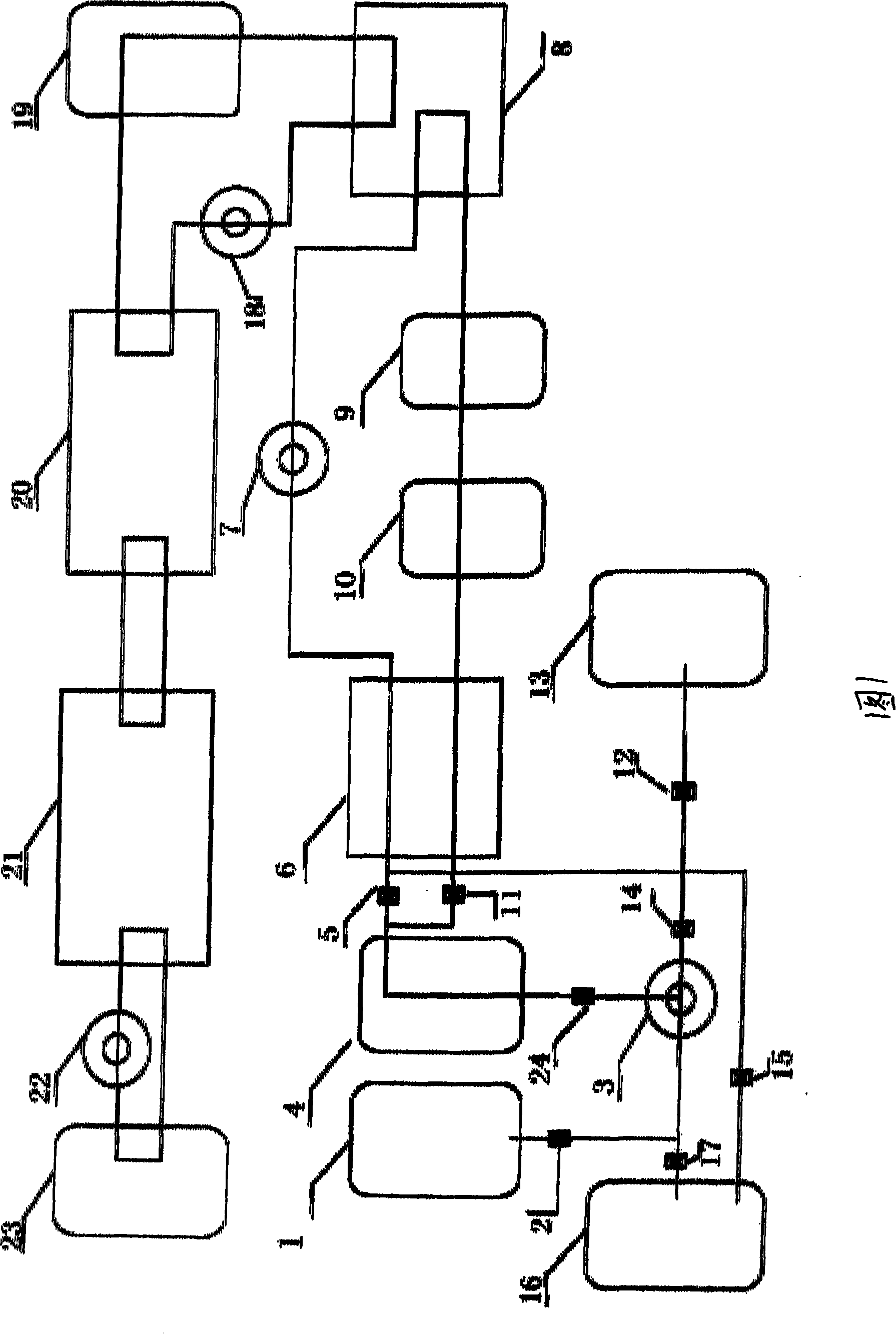

[0014] The wine energy-saving and environmental protection comprehensive treatment device is composed of the original wine tank 1, the first valve 2, the first wine pump 3, the primary filter 4, the second valve 5, the original wine and sake cold and heat exchanger 6, the second wine pump 7, Refrigerant and raw wine cold heat exchanger 8, anti-low temperature filter 9, anti-hydrolysis filter 10, third valve 11, fourth valve 12, sake tank 13, fifth valve 14, sixth valve 15, alcohol tank 16, the fourth valve Seven valves 17, a refrigerant pump 18, a refrigerant tank 19, a refrigerant and refrigerant heat exchanger 20, a refrigerator 21, a water pump 22, an air and water-cooled heat exchanger 23, and a liquid discharge valve 24; A valve 2, the first wine pump 3 are connected with the primary filter 4, and the primary filter 4 is connected with the original wine cold heat exchanger 6 through the second valve 5, the original wine and sake cold heat exchanger 6, the second wine pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com