Large-area high-efficiency carbon fiber coating process

A carbon fiber, high-efficiency technology, applied in the field of large-area and high-efficiency carbon fiber coating process, can solve problems such as carbon fiber prepreg coating process not involved, achieve moderate equipment and process costs, increase impact resistance, surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

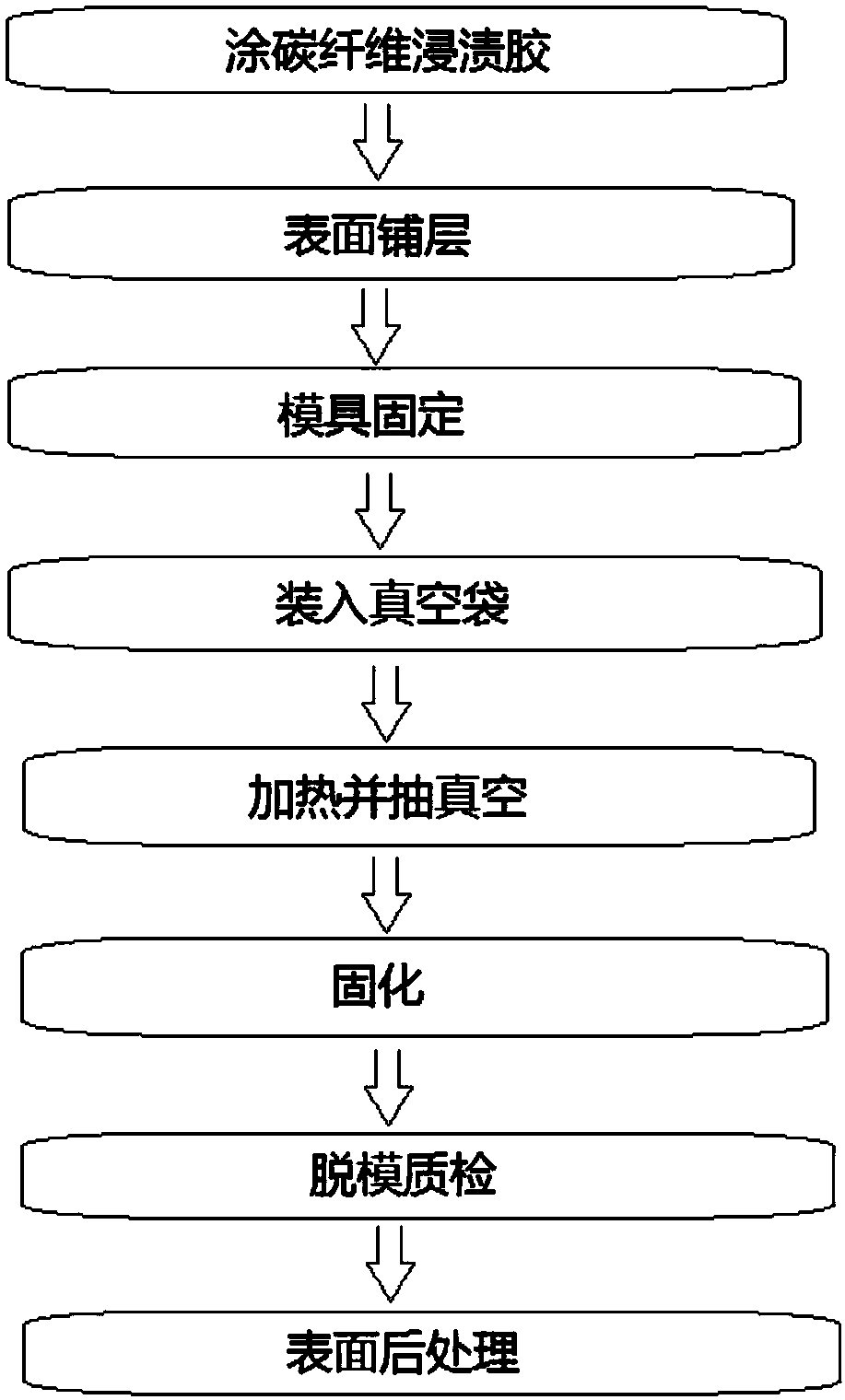

[0040] The covered part 2 is a metal part, and the carbon fiber coating on the surface of the metal part includes the following steps:

[0041] S1. Apply epoxy resin impregnating glue: evenly coat a layer of epoxy resin impregnating glue (including curing agent) on the surface of the metal parts.

[0042] S2. Surface layering: cutting carbon fiber prepreg 3 of appropriate size, and laying carbon fiber prepreg 3 with a K number of 3K on the surface of the metal part in one or more layers.

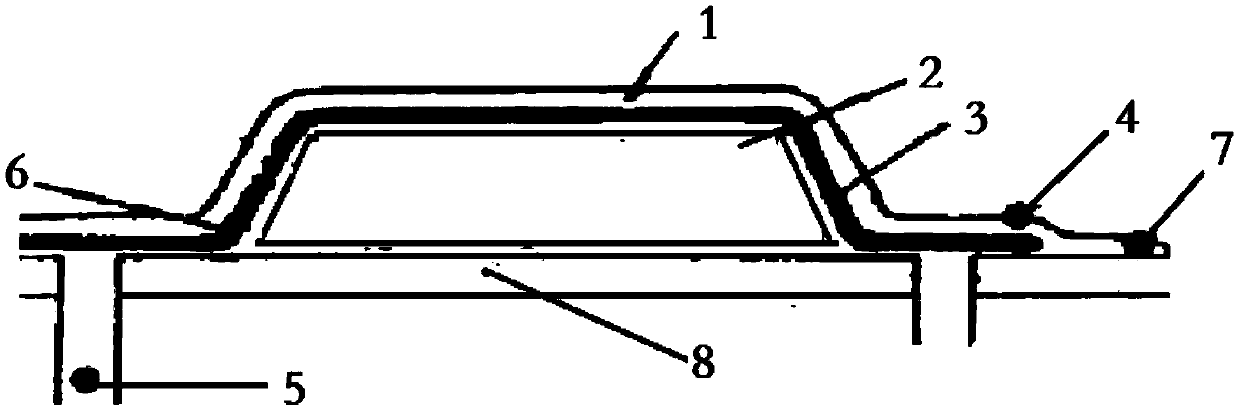

[0043] S3. Mold fixing: Cover the carbon fiber prepreg 3 with a layer of polyvinylidene chloride (PVDC) film 6; apply a layer of release agent to the aluminum alloy mold 1, and press the aluminum alloy mold 1 to the carbon fiber prepreg 3 on.

[0044] S4. Vacuum bagging 4: Put the aluminum alloy mold 1 object etc. into the vacuum bag 4, then insert the vacuum tube 5, and seal it tightly with the vacuum sealing mud 7.

[0045] S5. Heating and vacuuming: Put it into a heating oven, set the tem...

Embodiment 2

[0050] The covered part 2 is an engineering plastic part, and the carbon fiber coating on the surface of the engineering plastic part includes the following steps:

[0051] S1. Apply epoxy resin impregnating glue: evenly coat a layer of epoxy resin impregnating glue (including curing agent) on the surface of engineering plastic parts.

[0052] S2. Surface layering: cut the carbon fiber prepreg 3 of appropriate size, and lay the carbon fiber prepreg 3 with a K number of 3K on the surface of the engineering plastic part.

[0053] S3. Mold fixing: Cover the carbon fiber prepreg 3 with a layer of polyvinylidene chloride (PVDC) film 6; apply a layer of release agent to the aluminum alloy mold 1, and press the aluminum alloy mold 1 to the carbon fiber prepreg 3 on.

[0054] S4. Vacuum bagging 4: Put the aluminum alloy mold 1 object etc. into the vacuum bag 4, then insert the vacuum tube 5, and seal it tightly with the vacuum sealing mud 7.

[0055] S5. Heating and vacuuming: Put i...

Embodiment 3

[0060] The covered part 2 is a foam plastic part, and the carbon fiber coating on the surface of the foam plastic part comprises the following steps:

[0061] S1. Apply epoxy resin impregnating glue: evenly coat a layer of epoxy resin impregnating glue and curing agent on the surface of the foam plastic part.

[0062] S2. Surface layering: cut the carbon fiber prepreg 3 of appropriate size, and spread the carbon fiber prepreg 3 with a K number of 1K on the surface of the foam plastic part in one layer.

[0063] S3, mold fixing: cover one layer of polyvinylidene chloride (PVDC) film 6 on the carbon fiber prepreg 3; select the aluminum alloy material as the mold material of the component; apply a layer of release agent to the aluminum alloy mold 1, and The aluminum alloy mold 1 is pressed onto the carbon fiber prepreg 3 .

[0064] S4. Vacuum bagging 4: Put the aluminum alloy mold 1 object etc. into the vacuum bag 4, then insert the vacuum tube 5, and seal it tightly with the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com