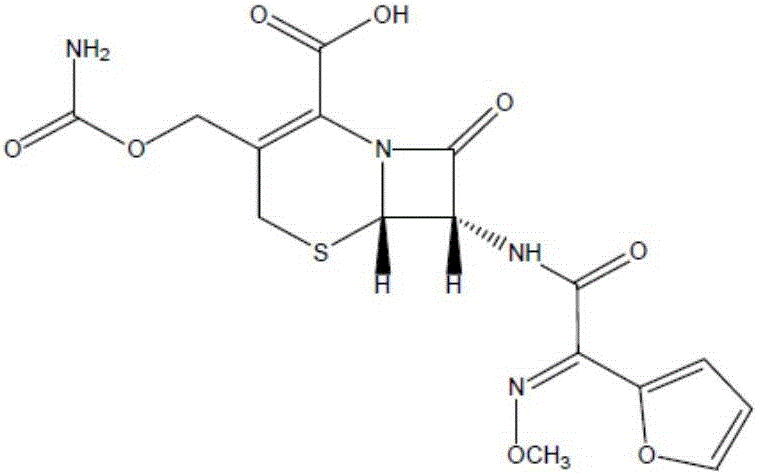

Preparation process for cefuroxime acid crystallization

A technology for cefuroxime acid and a preparation process, which is applied to the field of preparation technology of cefuroxime acid crystallization, can solve the problems of filtration, difficulty in drying, long production cycle, small product particle size, etc. Complete, lower production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 360mL of the cefuroxime acid feed solution prepared by the upstream process and add it to a 500mL crystallizer, control the temperature at 22°C, and stir at a rate of 100r / min to obtain Liquid A. Add 10.8mL of dichloromethane and 7.2mL of acetonitrile to Liquid A, Get Liquid B. Add hydrochloric acid dropwise to liquid B until the pH value is 3.9. During this process, the stirring speed is 180r / min, so that hydrochloric acid and liquid B can be mixed rapidly to obtain liquid C. Add seed crystals to liquid C, the amount of seed crystals is 0.7g, and grow crystals. During crystal growth, the stirring speed is kept at 110r / min, and the crystal growth time is 20min, to obtain crystal slurry A. Continue to add hydrochloric acid dropwise to the magma A, stop adding acid when the pH value is adjusted to 2.0, the acid dripping time is 4.5h, and the stirring speed is 100r / min to obtain the magma B. Crystal slurry B was grown for 15 minutes at a stirring speed of 110 r / min t...

Embodiment 2

[0035] Take 200mL of the cefuroxime acid feed liquid prepared in the upstream process and add it to a 500mL crystallizer, control the temperature at 24°C, and stir at a rate of 105r / min to obtain Liquid A, and add 6mL of tetrahydrofuran to Liquid A to obtain Liquid B. Add hydrochloric acid dropwise to liquid B until the pH value is 4.2. During this process, the stirring speed is 180r / min, so that hydrochloric acid and liquid B can be mixed rapidly to obtain liquid C. Add seed crystals to liquid C, the amount of seed crystals is 0.7g, and grow crystals. During crystal growth, the stirring speed is kept at 120r / min, and the crystal growth time is 35min, to obtain crystal slurry A. Continue to add hydrochloric acid dropwise to the magma A, stop adding acid when the pH value is adjusted to 1.3, the acid dripping time is 4 hours, the stirring speed is 130r / min, and the magma B is obtained. The crystal slurry B was grown for 25 minutes, and the stirring speed was 120 r / min during th...

Embodiment 3

[0037] Take 200mL of the cefuroxime acid feed solution prepared by the upstream process and add it to a 500mL crystallizer, control the temperature at 22°C, and stir at a rate of 100r / min to obtain Liquid A. Add 10mL of isopropanol and 4mL of acetonitrile to Liquid A to obtain liquid b. Add hydrochloric acid dropwise to liquid B until the pH value is 4.1. During this process, the stirring speed is 200r / min, so that hydrochloric acid and liquid B can be mixed rapidly to obtain liquid C. Add seed crystals to liquid C, the amount of seed crystals is 0.3g, and grow crystals. During the crystal growth, the stirring speed is kept at 110r / min, and the crystal growth time is 40min, to obtain crystal slurry A. Continue to add hydrochloric acid dropwise to magma A, and stop adding acid when the pH value is adjusted to 2.5. The acid dripping time is 7 hours, and the stirring speed is 150r / min to obtain magma B. Crystal slurry B was grown for 15 minutes at a stirring speed of 100 r / min t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com