Composite powder material of fly ash hollow microspheres with surfaces cladded with nanometer magnesium hydroxide and preparation method thereof

A technology of nano-magnesium hydroxide and hollow microspheres, which is applied in chemical instruments and methods, water treatment of special compounds, water/sewage treatment, etc., can solve the problems of high cost and difficult filtration of water treatment agents, and achieve the goal of solving difficult filtration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 4.35g of the calcined sample of fly ash hollow microspheres, the solid-to-liquid ratio is 1:3, heat to 80°C, stir for 20min, and add dropwise a sodium hydroxide solution with a concentration of 0.25mol / l and a dropping rate of 7ml / min 500ml; concentration is 0.15mol / l, and the magnesium sulfate solution 417ml that dripping speed is 5ml / min, adjusts pH to be 12 after dropwise addition is completed, continues to react for 120min, after aging 30min, filter, wash, dry, break up and depolymerize, Measure whiteness.

Embodiment 2

[0027] Weigh 4.35g of the calcined sample of fly ash hollow microspheres, the solid-to-liquid ratio is 1:10, heat to 25°C, stir for 30min, and add dropwise a sodium hydroxide solution with a concentration of 0.25mol / l and a dropping rate of 2ml / min 500ml, the concentration is 0.15mol / l, and the rate of addition is 2ml / min magnesium sulfate solution 417ml. After the dropwise addition, adjust the pH to 7, continue to react for 30 minutes, then age for 60 minutes, filter, rinse, dry, break up and depolymerize, and measure the whiteness.

Embodiment 3

[0029] Weigh 5.8g of the calcined sample of fly ash hollow microspheres, the solid-to-liquid ratio is 1:5, heat to 90°C, stir for 20min, and add dropwise a sodium hydroxide solution with a concentration of 0.25mol / l and a dropping rate of 5ml / min 466.7ml and 455.5ml of magnesium sulfate solution with a concentration of 0.15mol / min and a dropping rate of 5ml / min, adjust the pH to 10 after the addition is completed, continue to react for 90min, then age for 30min, filter, rinse, dry, break up and dissolve Gather, measure whiteness.

[0030] Table 1 Whiteness test and analysis results of example samples and raw materials

[0031]

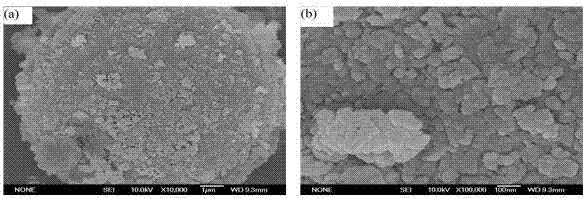

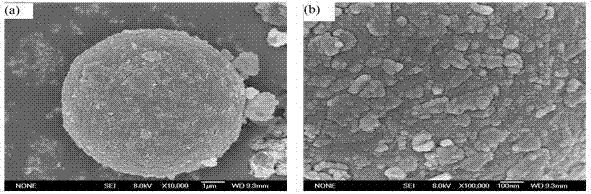

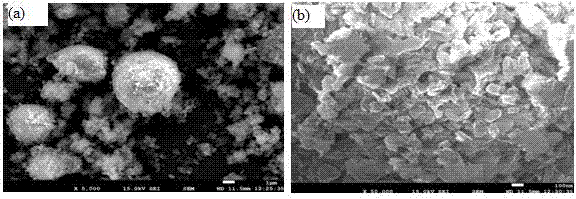

[0032] figure 1 It is the SEM picture of the nano-magnesium hydroxide composite powder coated on the surface of the fly ash hollow microspheres prepared in Example 1 of the present invention. In the figure: a. Fly ash hollow microspheres coated with magnesium hydroxide × 10,000 times; b. Fly ash hollow microspheres coated with magnesium hydroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com