Self-lubricating ceramic cutter material with h-BN@Ni core-shell structure composite powder added and preparation method of self-lubricating ceramic cutter material

A technology of composite powder and core-shell structure, which is applied in the field of ceramic tool materials, can solve the problems of small elimination effect and small promotion effect of ceramic tool material densification, so as to improve sintering density, improve mechanical properties and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

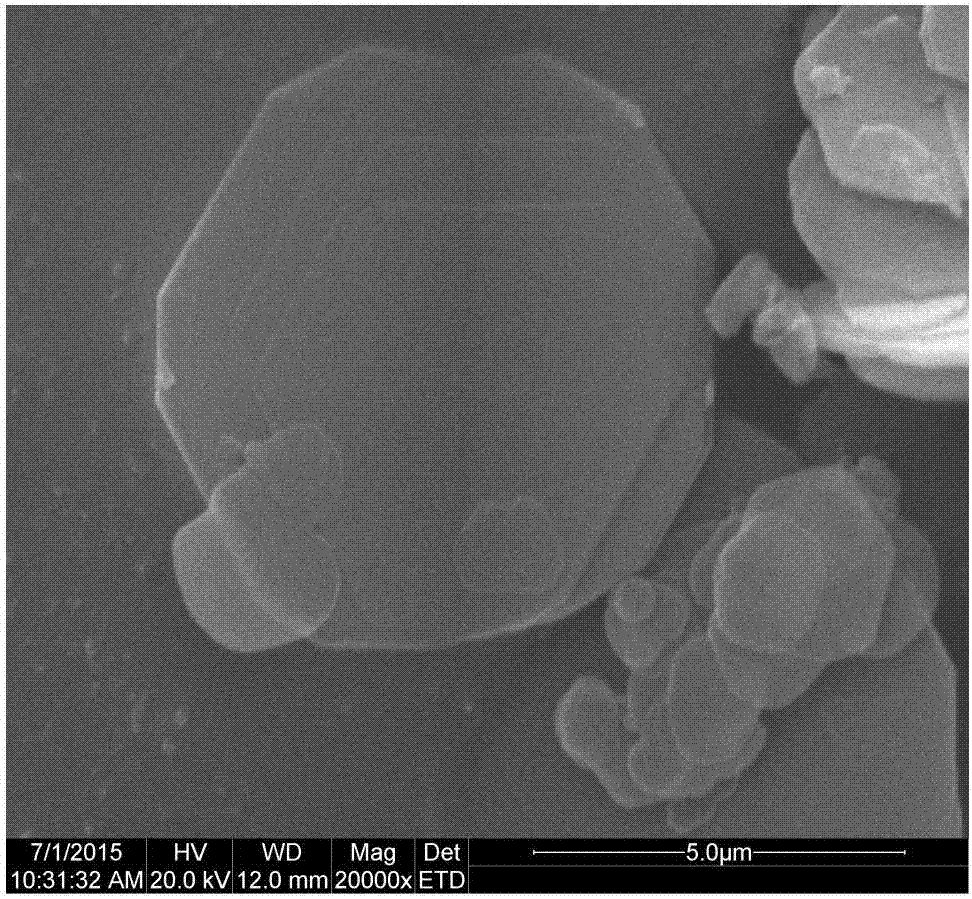

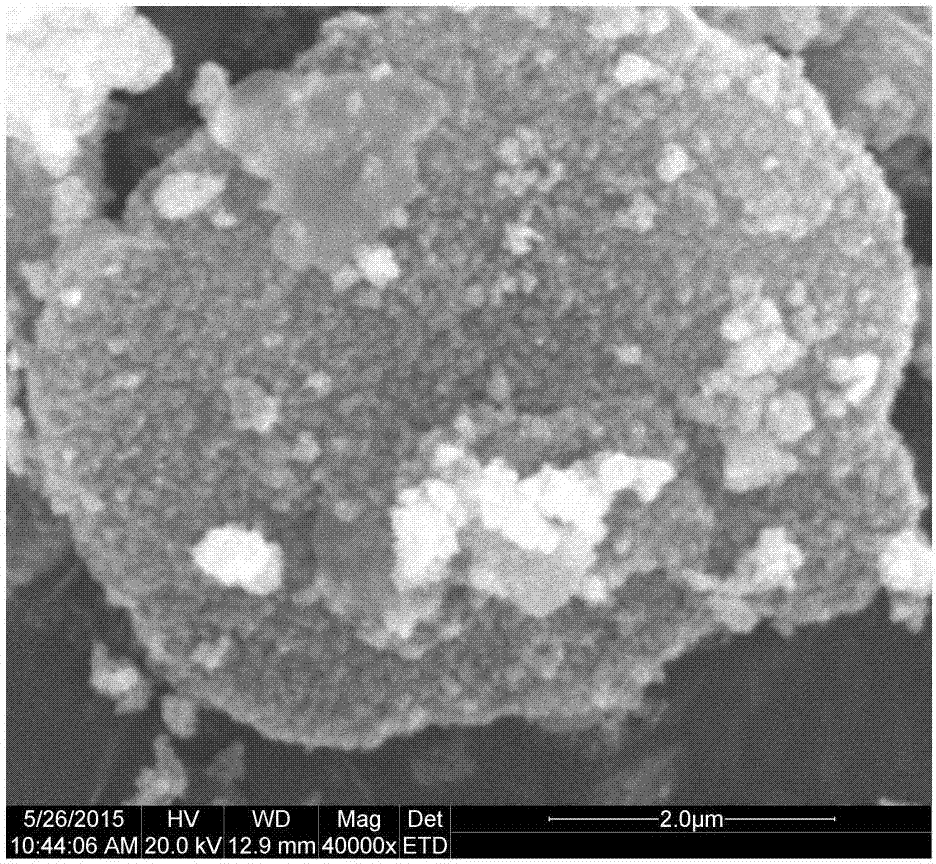

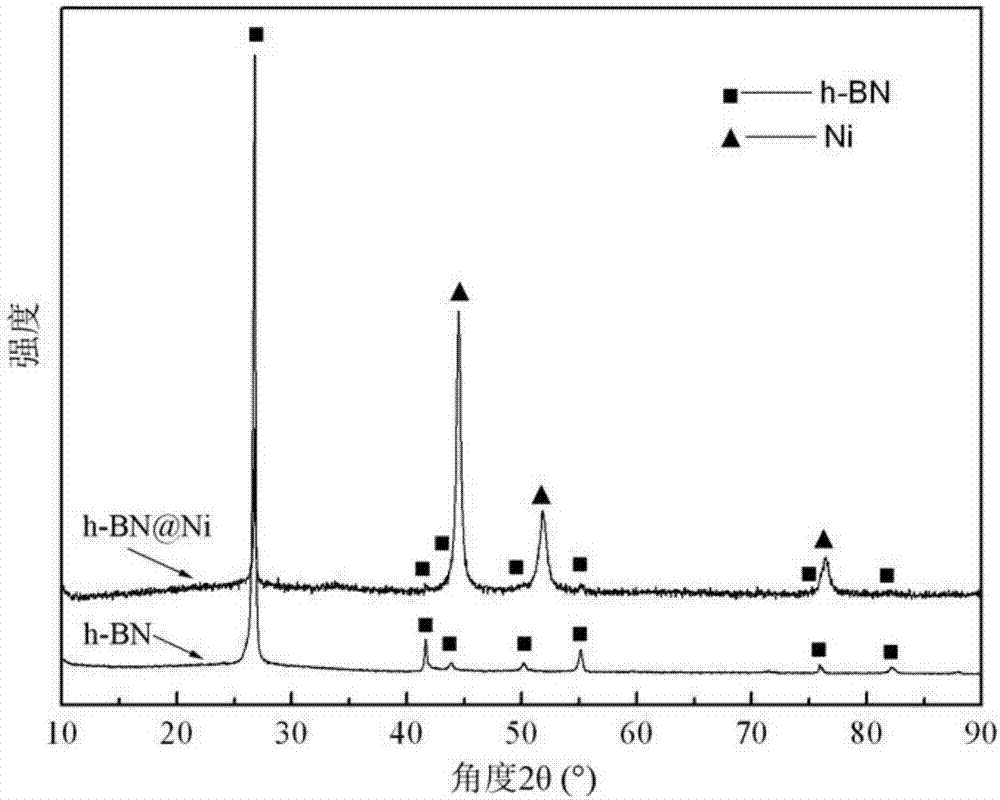

[0059] Example 1: A self-lubricating ceramic tool material with h-BN@Ni core-shell structure composite powder added, the mass percentage of each component is: α-Al 2 o 3 32.5%, (W,Ti)C 65%, h-BN@Ni 2% based on the mass of h-BN in the composite powder, MgO 0.5%.

[0060] The preparation method is as follows:

[0061] (1) Sensitization and activation of h-BN powder

[0062] Weigh 2.5g SnCl 2 2H 2 O, add 100mL of absolute ethanol and stir to dissolve to obtain a sensitization solution; 0.05gPdCl 2 Add 1mL of concentrated hydrochloric acid, stir to dissolve, then add distilled water to 100mL to obtain an activation solution. Weigh 2g of h-BN raw material powder into the above sensitization solution, ultrasonically shake for 2min, centrifuge and wash once with absolute ethanol, and then wash once with distilled water. The sensitized h-BN powder was added into the activation solution, ultrasonically oscillated for 5 min, centrifuged and washed with absolute ethanol for 3 time...

Embodiment 2

[0080] Example 2: A self-lubricating ceramic tool material with h-BN@Ni core-shell structure composite powder added, the mass percentage of each component is: α-Al 2 o 3 37%, (W,Ti)C 58.5%, h-BN@Ni 4% based on the mass of h-BN in the composite powder, MgO 0.5%. The preparation method is as follows:

[0081] (1) Sensitization and activation of h-BN powder

[0082] Weigh 5g SnCl 2 2H 2 O, added to 200mL absolute ethanol and stirred to dissolve to obtain a sensitization solution. 0.1gPdCl 2 Add 2mL of concentrated hydrochloric acid, stir to dissolve, then add distilled water to 200mL to obtain an activation solution. Weigh 4g of h-BN raw material powder into the sensitization solution, ultrasonically shake for 3min, centrifuge and wash once with absolute ethanol, and then wash once with distilled water. The sensitized h-BN powder was added to the activation solution, ultrasonically oscillated for 7 minutes, centrifuged and washed with absolute ethanol 4 times, dried in a ...

Embodiment 3

[0099] Example 3: A self-lubricating ceramic tool material with h-BN@Ni core-shell structure composite powder added, the mass percentage of each component is: α-Al 2 o 3 40%, (W,Ti)C 53%, h-BN@Ni 6% based on the mass of h-BN in the composite powder, MgO 1%. The preparation method is as follows:

[0100] (1) Sensitization and activation of h-BN powder

[0101] Weigh 10.5g SnCl 2 2H 2 O, added to 350mL absolute ethanol and stirred to dissolve to obtain a sensitization solution. 0.3gPdCl 2 Add 4mL of concentrated hydrochloric acid, stir to dissolve, then add distilled water to 350mL to obtain an activation solution. Weigh 6g of h-BN raw material powder into the sensitization solution, ultrasonically shake for 5min, centrifuge and wash once with absolute ethanol, and then wash once with distilled water. The sensitized h-BN powder was added to the activation solution, ultrasonically oscillated for 7 minutes, centrifuged and washed with absolute ethanol 4 times, dried in a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com