C30 tailing sand concrete and preparation method thereof

A technology of tailings sand and concrete, which is applied in the field of building materials, can solve the problems of large concrete slump loss, inability to meet underwater construction, and easy dispersion of concrete, so as to achieve difficult dispersion, increase hydrophobic effect, improve workability and resistance The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

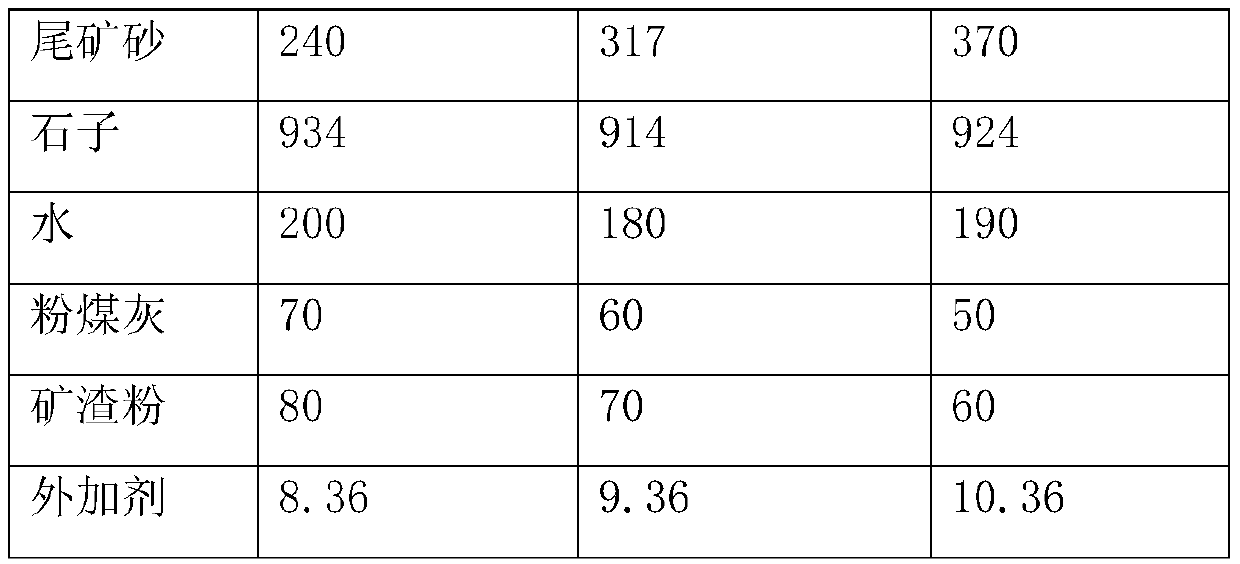

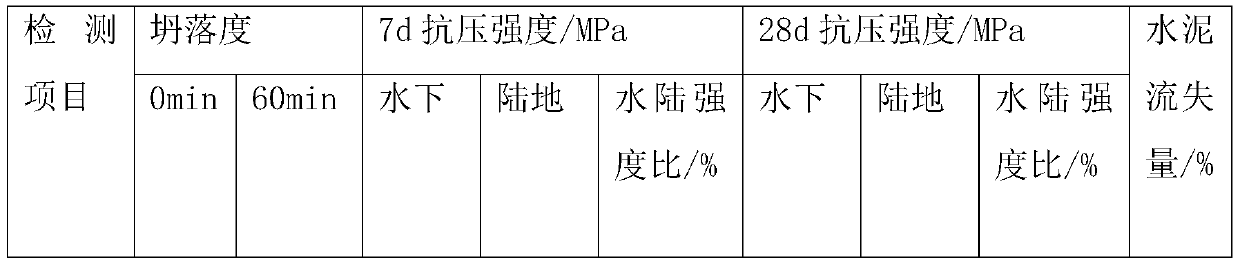

Method used

Image

Examples

preparation example 1-3

[0042] The coal gangue powder in the preparation example 1-3 is selected from the coal gangue of Wangfenggang Coal Preparation Plant in Huainan City, Anhui Province. The main components (wt%) are 56.35% silicon dioxide, 32.79% aluminum oxide, 5.85% iron sesquioxide, and 3.11% calcium oxide. Magnesium oxide 1.18, the silane coupling agent is selected from the silane coupling agent of model KH-550 sold by Henan Weichen Chemical Products Co., Ltd.

preparation example 1

[0043] Preparation Example 1: Select coal gangue to remove impurities, soak it in water for 2 hours, dry and pulverize it until the average particle size is 3.0 μm; dissolve 1 kg of silane coupling agent with 8 kg of water, add 20 kg of coal gangue powder, and stir at 80 ° C for reaction. Washing, suction filtration, and drying at 110°C to obtain modified gangue powder.

preparation example 2

[0044] Preparation Example 2: Select coal gangue to remove impurities, soak it in water for 2.5 hours, dry and crush it to an average particle size of 3.3 μm; dissolve 1.3 kg of silane coupling agent with 9 kg of water, add 23 kg of coal gangue powder, and stir at 85°C for reaction , washed, suction filtered, and dried at 115°C to obtain modified gangue powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com