A Fuel Injection System for Regeneratively Cooled Knock Combustion Chamber

A fuel injection system, regenerative cooling technology, applied in intermittent injection devices, jet propulsion devices, machines/engines, etc., can solve problems such as pressure pulsation, achieve the effects of avoiding pressure pulsation, realizing conversion and utilization, and realizing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the accompanying drawings.

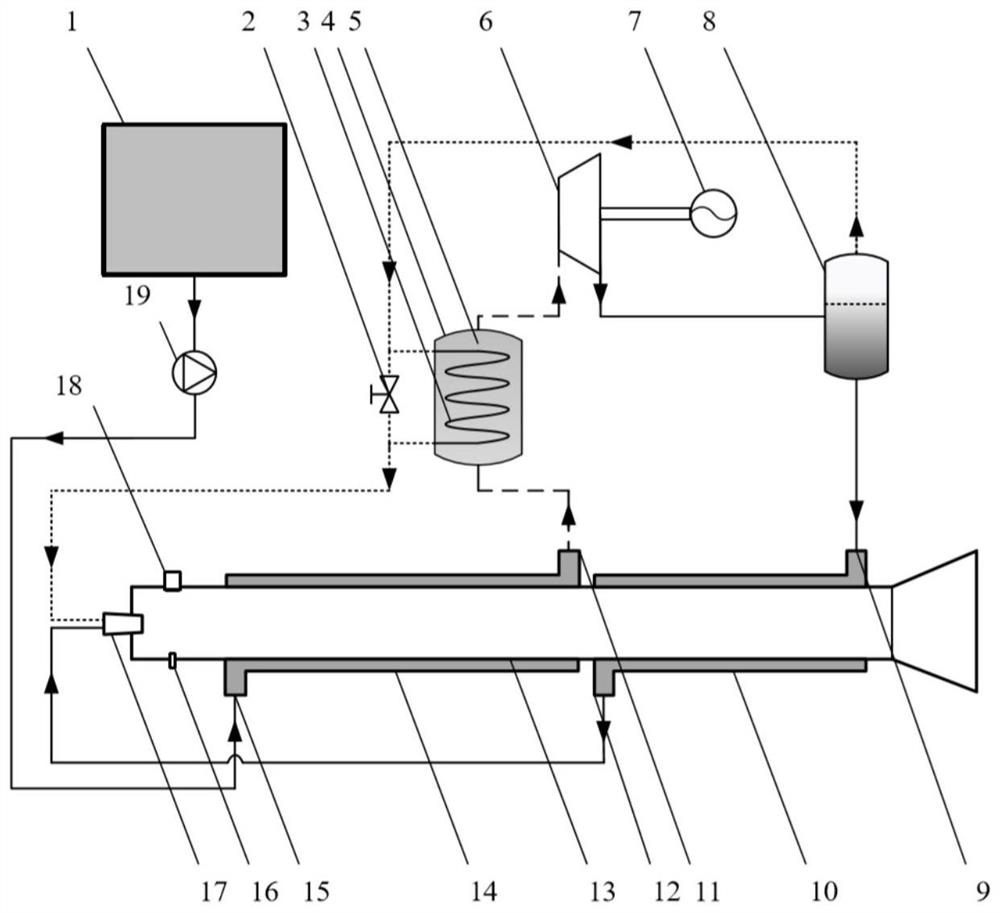

[0025] The present invention is a fuel injection system suitable for regenerative cooling detonation combustion chamber, such as figure 1 As shown, it includes: fuel tank 1, bypass regulating valve 2, regenerator gaseous fuel flow line 3, regenerator 4, regenerator mixed fuel flow chamber 5, low pressure ratio turbine 6, excitation generator 7. Gas-liquid separation chamber 8, second-stage heat exchanger inlet of detonation combustion chamber 9, second-stage heat exchanger of detonation combustion chamber 10, first-stage heat exchanger outlet of detonation combustion chamber 11, detonation combustion chamber The outlet of the second stage heat exchanger 12, the wall surface of the detonation combustion chamber 13, the first stage heat exchanger of the detonation combustion chamber 14, the inlet of the first stage heat exchanger of the detonation combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com