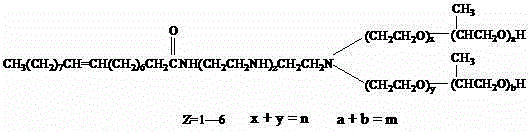

Synthesis method and application of oleic acid-polyethylene polyamine polyether

A technology of ethylene polyamine polyether and synthesis method, which is applied in the directions of chemical characteristics of fibers, textiles and papermaking, single-component cellulose rayon, etc., can solve the problems of difficulty in filtration, poor quality of finished products, poor spinning forming, etc., Achieve good technical effects, reduce surface tension, and promote smooth production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] 1) Synthesis of intermediates is based on (calculated by weight ratio).

[0020] Example 1. In the reaction kettle equipped with mechanical stirring, thermometer and vacuum device, pump 745kg of oleic acid and 305kg of diethylenetriamine, start heating and stirring, raise the temperature to 170±10°C, start the vacuum pump, and put the reaction The generated water is taken out, and the heating is stopped until the water is completely discharged in about 5 hours, and the temperature is lowered to obtain the amidation intermediate of oleic acid diethylenetriamine end group.

[0021] In this embodiment, 1000Kg of intermediate synthetic raw materials is taken as an example, oleic acid is 745Kg, diethylenetriamine is 305Kg, and about 50Kg of water is lost.

[0022] Example 2. In the reaction kettle equipped with mechanical stirring, thermometer and vacuum device, pump 624kg of oleic acid and 421kg of triethylenetetramine, start heating and stirring, raise the temperature to 1...

Embodiment 5

[0030] Be 1000Kg oleic acid polyethylene polyamine polyether synthesis raw material among the embodiment 5, intermediate 450Kg, oxirane 550Kg.

[0031] Example 6, in a four-necked flask equipped with mechanical stirring, a thermometer and a vacuum distillation device, add 350 g of oleic acid tetraethylenepentamine obtained in the previous step, add 1.5 g of potassium hydroxide catalyst, start heating, and at a temperature of 100 ± 10 ℃ Start the vacuum pump, pump out the air in the bottle and the water in the intermediate body, turn off the vacuum, blow with nitrogen for 3 times, remove the air in the system, start adding ethylene oxide, at a temperature of 160±10°C, a pressure of 0.1-0.3 Under the condition of mpa, gradually add 490g of ethylene oxide, after the addition, continue to pass 160g of propylene oxide under this condition, after the addition, continue to react for 1 hour, stop the reaction, and obtain a brown clear liquid, which is oleic acid Tetraethylenepentamine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com