Two-step method for gasification of pulverized coal fluidized bed and device utilizing method

A technology of fluidized bed gasification and pulverized coal, which is applied in the direction of granular/powdered fuel gasification, chemical industry, and the manufacture of combustible gas, etc. It can solve the problems of affecting gasification efficiency, fragility, and poor thermal stability of lignite. Achieve the effects of improving gasification efficiency, reducing pollution, and improving sensible heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

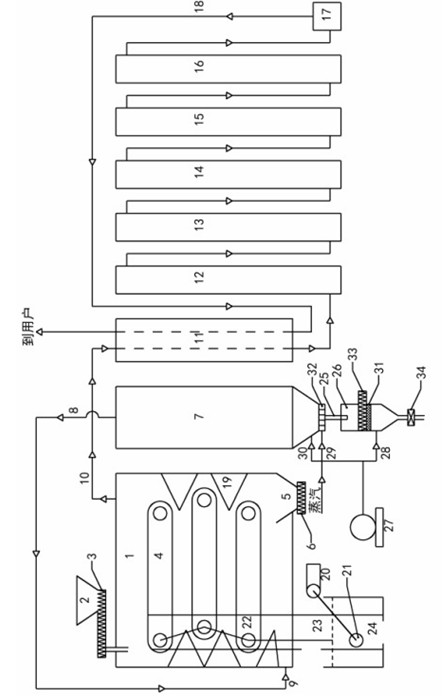

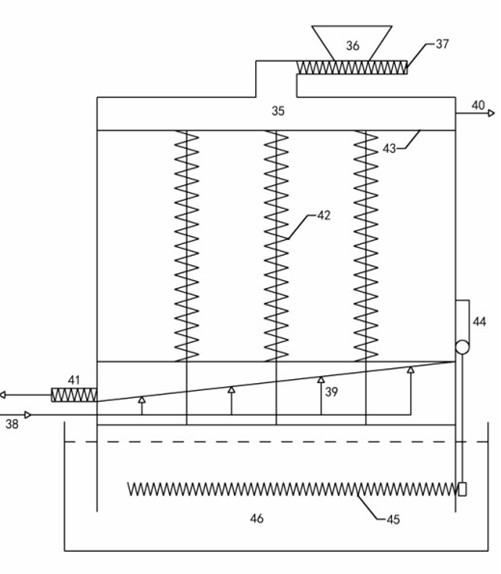

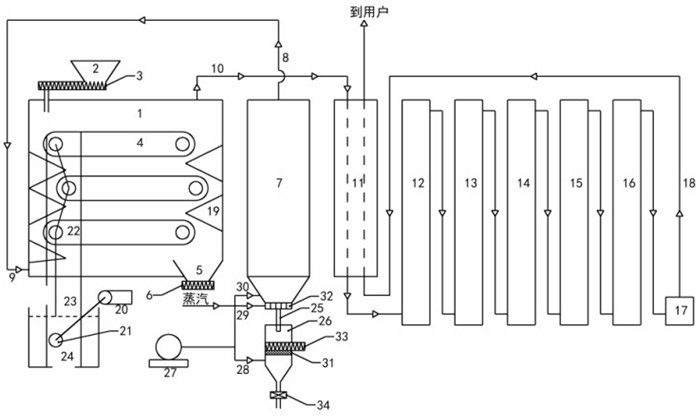

[0015] The two-step pulverized coal fluidized bed gasification device is to install a horizontal dry distillation tower in front of the gasifier to pretreat the raw coal, such as figure 1 As shown, the pulverized coal fluidized bed gasification device is mainly composed of a horizontal retort tower 1 with a horizontal cuboid structure, several layers of chain grates or chain mesh belts 4 in the horizontal retort tower are horizontally arranged in a staggered way up and down, and a gasifier 7 , gas heat exchanger 11, washing tower 12, intercooler A13, electric coke catcher 14, desulfurization tower 15, intercooler B16, fan or compressor A17, etc.; the gas inlet 9 of the horizontal dry distillation tower passes through the gas pipeline A8 Connect the gas outlet at the upper end of the gasifier, the gas outlet 10 of the horizontal dry distillation tower is connected to the gas heat exchanger 11, and the gas heat exchanger is connected to the scrubber scrubber 12, the intercooler A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com