Continuous dry-type methane fermenting device and methane preparing method

A biogas fermentation and dry process technology, applied in biochemical equipment and methods, fermentation, biological material sampling methods, etc., can solve problems such as gas sealing, and achieve the effects of ensuring air tightness, reliable sealing, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

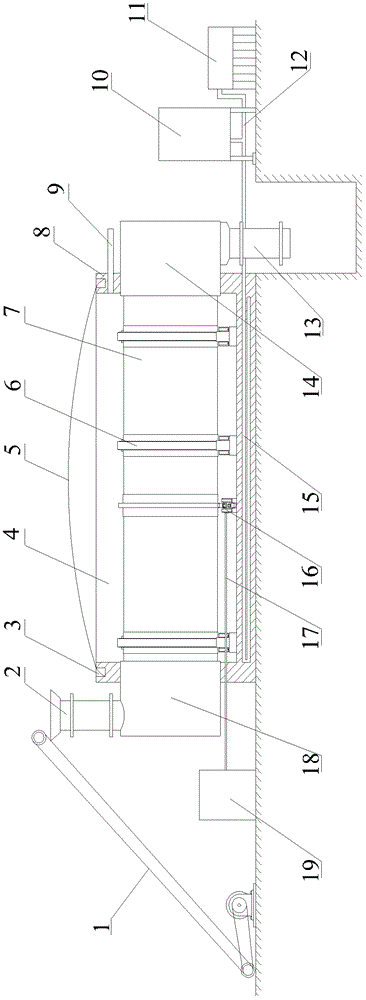

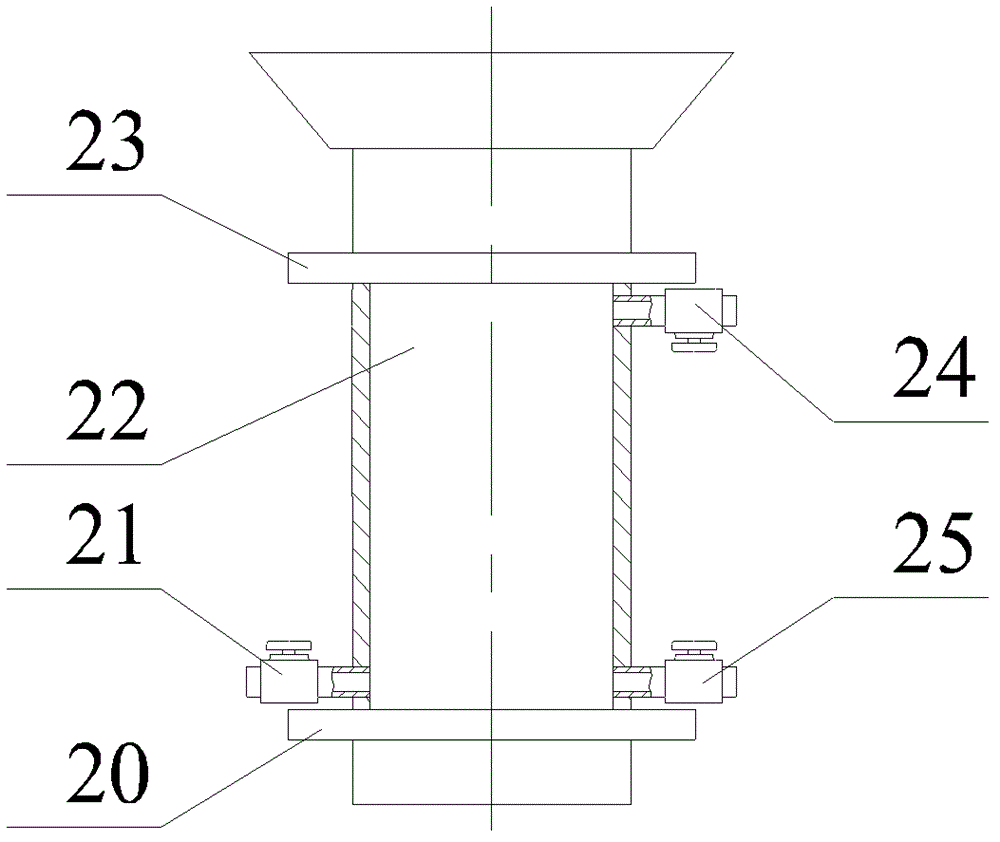

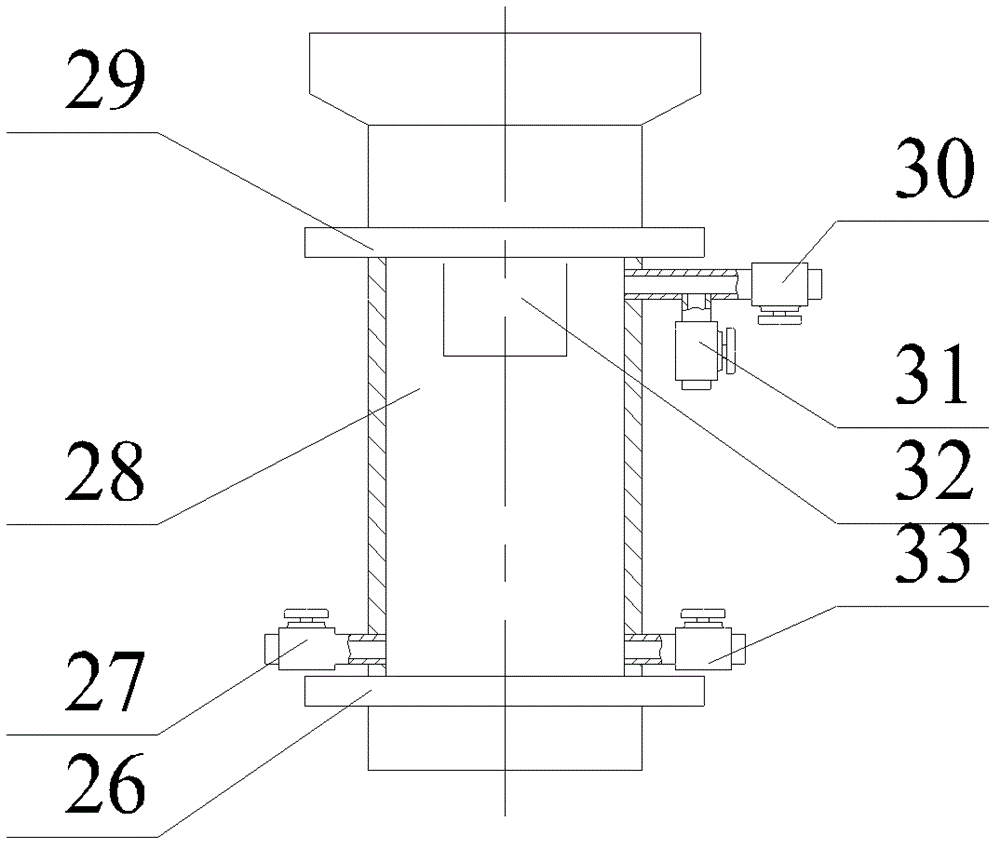

[0030] As shown in the figure, the invention is designed as follows: figure 1 As shown, the continuous dry biogas fermentation equipment is mainly composed of a feeding device 1, a feeding device 2, a concrete film tank reactor 4, a drum stirrer 6, a discharging device 13, and an auxiliary heating system. The specific connection method is as follows: the feeding device 1 is connected to the feeding device 2; the water tank 3 is installed on the top of the tank body 8; the concrete film tank reactor 4 is composed of the tank body 8 and its bottom surface and four vertical surfaces are composed of flexible membranes 5. On its top surface, the two ends of the concrete film tank reactor 4 are respectively installed with a first fixed cylinder 18 and a second fixed cylinder 14; the feeding device 2 and the discharging device 13 are respectively connected to the first fixed cylinder 18 and the second fixed cylinder 14 The drum agitator 6 is connected to the hydraulic motor 16, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com