Device for using sensible heat of blast furnace slag with high efficiency

A high-efficiency technology for blast furnace slag, which is applied in the direction of steam engine installations, energy efficiency improvement, recycling technology, etc., can solve the problems of unusable blast furnace slag sensible heat, pollution, etc., and achieve uniform diameter, good granulation effect, and good heat transfer effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

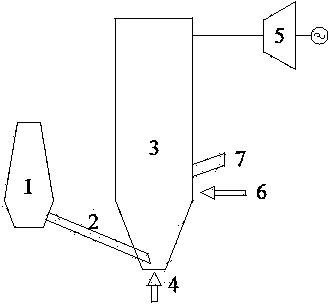

[0020] see figure 1 , the present invention relates to a device for efficiently utilizing the sensible heat of blast furnace slag, comprising a blast furnace 1, a circulating fluidized bed 3 and a steam turbine 5, and a sealed launder is arranged at the outlet of the blast furnace 1 and the inlet of the circulating fluidized bed 3 2. The upper part of the circulating fluidized bed 3 is connected with the steam turbine 5, and the circulating fluidized bed 3 is provided with a secondary air outlet 6 and a feed inlet 7.

[0021] A blast furnace is 3200m 3 , an average of about 100t of hot molten slag is produced per hour, and the slag is discharged once every 2.5 hours. The duration of the slag discharge is 2 hours, and the interruption is 0.5 hours. After adopting the present invention, 90% of the sensible heat of hot molten slag is converted into superheated steam. When the slag discharge is interrupted, it is supplemented with steel plant blast furnace gas, and the circulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com