A converter gas purification and waste heat recovery and utilization system

A waste heat recovery and converter gas technology, applied in furnaces, furnace components, waste heat treatment, etc., can solve the problems of converter gas recovery discontinuity, safety, large cross-section and airflow changes, etc., to prevent explosive smoke pollution, The effect of increasing the ratio of steel scrap and increasing the ratio of steel scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

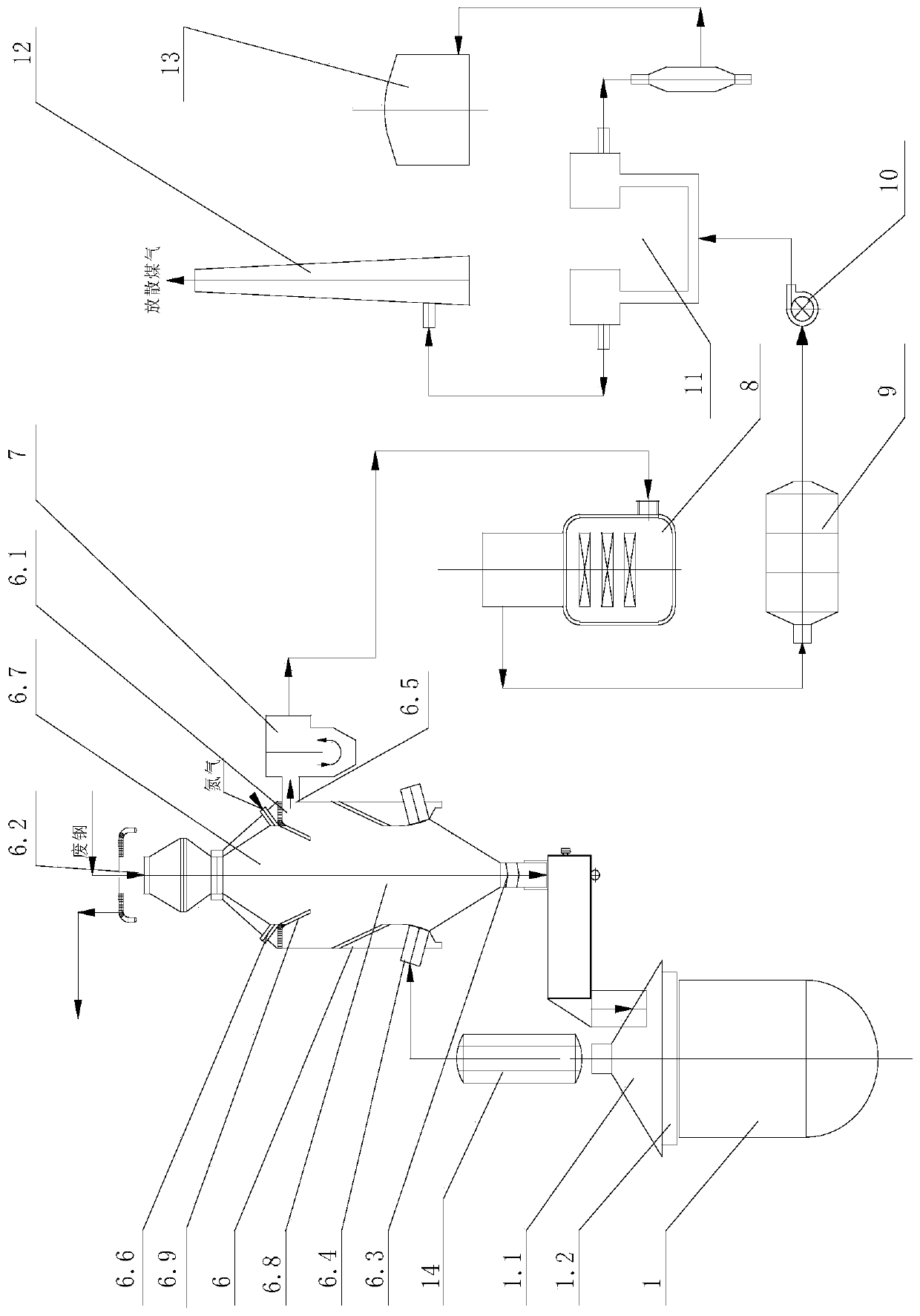

[0038] see figure 1 The system of the present invention includes a converter smelting system and a converter flue dust waste heat recovery purification conditioning system, the converter smelting system includes a converter 1 with a converter hood 1.1 and a movable skirt 1.2 and a cold material preheater 6 located above the converter 1 , the discharge port of the cold material preheater 6 is connected to the feed port on the converter hood 1.1, and the air inlet of the cold material preheater 6 is connected to the converter hood 1.1 through the vaporization cooling flue 14 The soot outlet of the cold material preheater 6 is connected to the gas outlet of the converter flue dust waste heat recovery purification conditioning system. In this embodiment, the cold material preheater includes a cold material preheater 6, and the input cold material is steel scrap.

[0039] The top of the cold material preheater 6 is provided with a material inlet 6.2, the bottom is provided with a ...

Embodiment 2

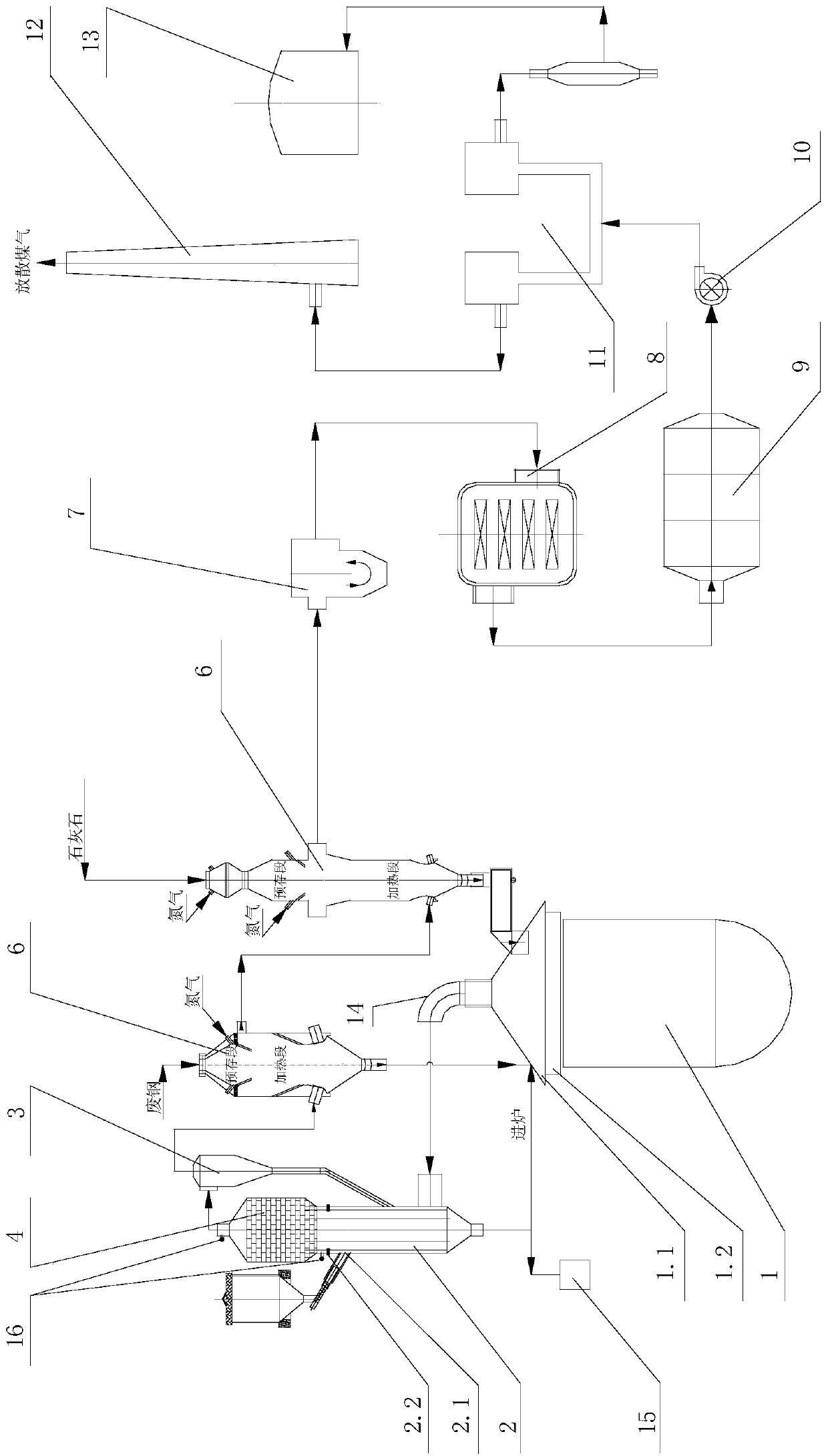

[0047] see figure 2 , and the difference from Example 1 is: the outlet of vaporization cooling flue gas 14 is connected with the air inlet of the fluidized bed gasifier 2, regenerator 4, cyclone dust collector 3 and the cold material preheater 6 , the ash outlet of the cyclone dust collector 3 is connected to the fluidized bed gasifier 2 . The material dropped into the fluidized bed gasifier 2 is medical waste; the cold material preheater 6 is two in series, and the steelmaking cold material dropped into the first cold material preheater 6 is scrap steel, The steelmaking cold material dropped into in the second cold material preheater 6 is limestone. All the other are with embodiment 1.

[0048] Wherein, the fluidized bed gasifier 2 is provided with a solid material feed port 2.1 and a liquid material injection port 2.2 for feeding medical waste or high-concentration organic waste liquid, and the top of the fluidized bed gasifier 2 is provided with There is a regenerator 4...

Embodiment 3

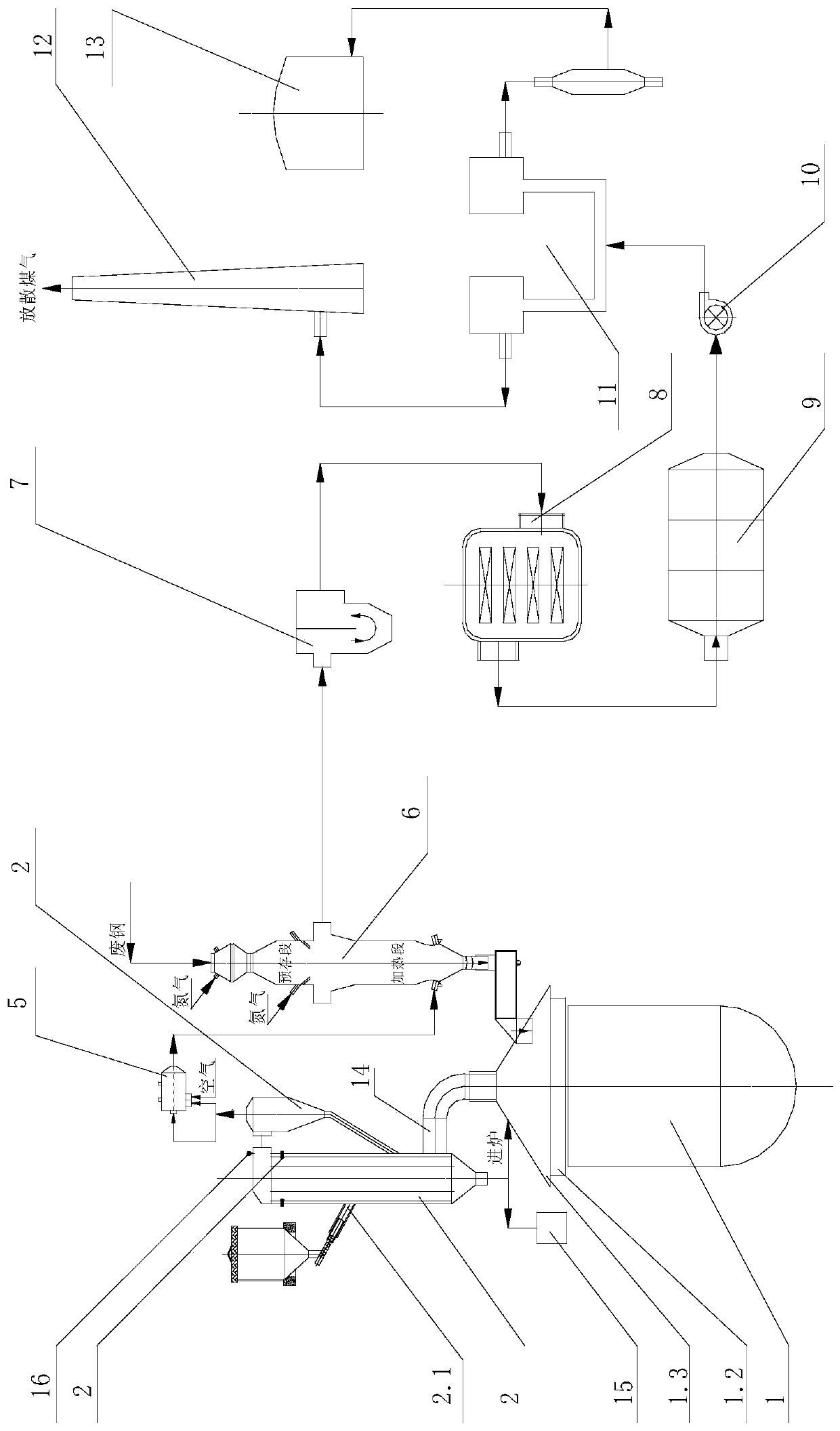

[0054] see image 3 , and the difference from Example 2 is that the regenerator 4 is canceled, the fluidized bed gasifier 2 is connected with a cold material preheater 6 through the cyclone dust collector 3, the combustion chamber 5, and the liquid material is sprayed into the inlet 2.2. The material put into the fluidized bed gasifier 2 is high-concentration organic waste liquid, and the steelmaking cold material in the cold material preheater 6 is steel scrap. All the other are with embodiment 2.

[0055] The process is different from Example 1 in that: the mixed gas from the fluidized bed reactor is first dedusted by the cyclone dust collector 3, and then sent into the cold material preheater 6 through the combustion chamber 5, and controlled to enter the cold material preheater. The mixed gas temperature of heater 6 is at 800-1000 ℃. When the combustion chamber 5 is installed, when the converter starts the oxygen blowing smelting stage, high-concentration organic waste l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com