Processing method for salix babylonica wood for preparing heat-resistant strainer

A processing method and technology of the willow tree, applied in the direction of wood treatment, wood heat treatment, wood treatment details, etc., can solve the problems of restricting the development and use of natural renewable material fences, achieve economical and environmental protection, and reduce pore space. , Improve the effect of antibacterial myocardial infarction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

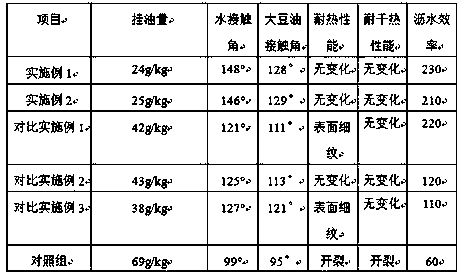

Examples

Embodiment 1

[0018] A processing method for preparing tamarisk wood for heat-resistant hedgerows, comprising the steps of:

[0019] Step 1. Hydrothermal treatment of tamarisk wood: (1.1) Select fresh and straight tamarisk branches, peel and leave the core, and the peeled tamarisk will have no pests and diseases, and the shape will be complete; the peeled tamarisk will be treated For the first cooking, the cooking system is an aqueous solution containing 15% sodium acetate and 15% ethanol, and cook for 15 minutes; (1.2) Rinse the cooked tamarisk wood with water for 12 minutes, and then drain the water Drain; the drained tamarisk wood is aged, and the aging process is to put the tamarisk wood into a ceramic pot for aging, adopting the method of putting a layer of tamarisk wood and a layer of salt, pressing it with stones In fact, the ratio of tamarisk wood to edible salt is 100:30. After aging for 2 days, turn over the lower tamarisk wood, then age it for another 3 days, remove it, and then ...

Embodiment 2

[0026] A processing method for preparing tamarisk wood for heat-resistant hedgerows, comprising the steps of:

[0027] Step 1. Hydrothermal treatment of tamarisk wood: (1.1) Select fresh and straight tamarisk branches, peel and leave the core, and the peeled tamarisk will have no pests and diseases, and the shape will be complete; the peeled tamarisk will be treated For the first cooking, the cooking system is an aqueous solution containing 10% sodium acetate and 10% ethanol, and cook for 10 minutes; (1.2) Rinse the cooked tamarisk wood with water for 10 minutes, and then drain the water Drain; the drained tamarisk wood is aged, and the aging process is to put the tamarisk wood into a ceramic pot for aging, adopting the method of putting a layer of tamarisk wood and a layer of salt, pressing it with stones In fact, the ratio of tamarisk wood to edible salt is 100:12, and the aging will be turned over once a day, and the lower tamarisk wood will be turned over, then aged for an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com