Sterilizing cabinet power control device and method

A power control and disinfection cabinet technology, applied in the field of disinfection cabinets, can solve the problems of long disinfection time, low heating power, and large power consumption, and achieve the effect of shortening the heating time and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

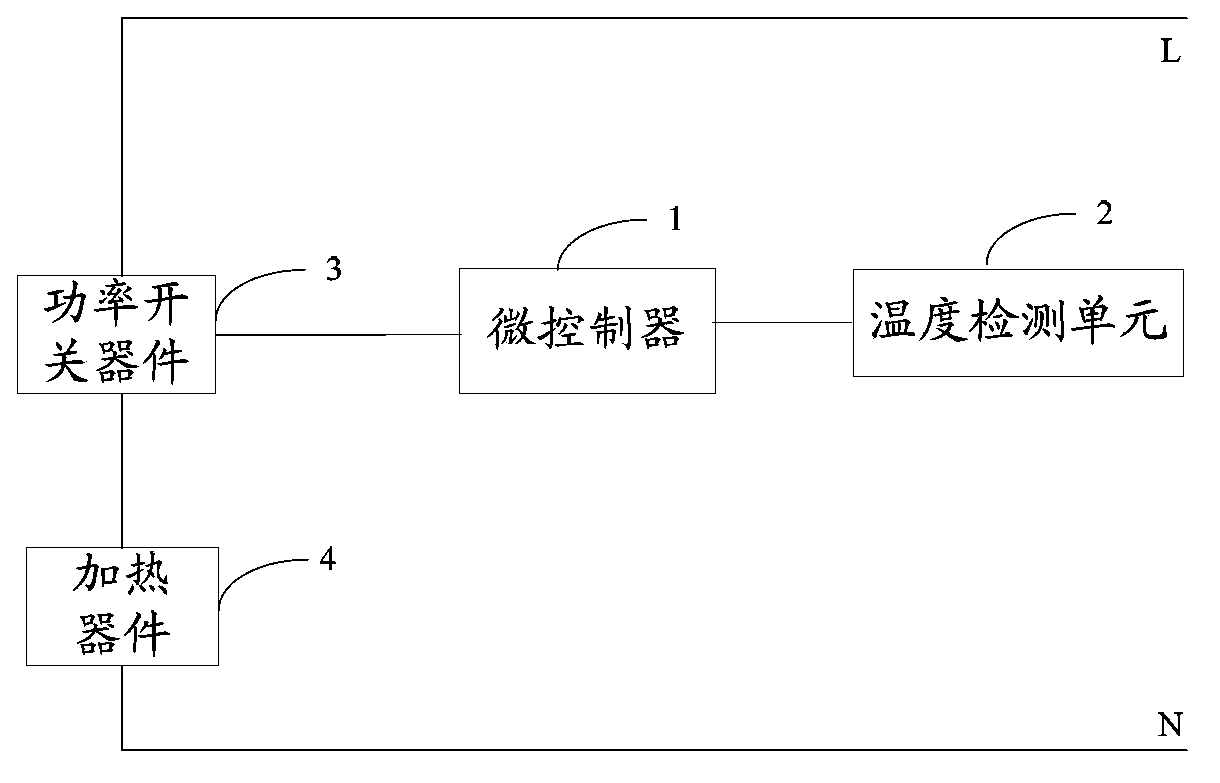

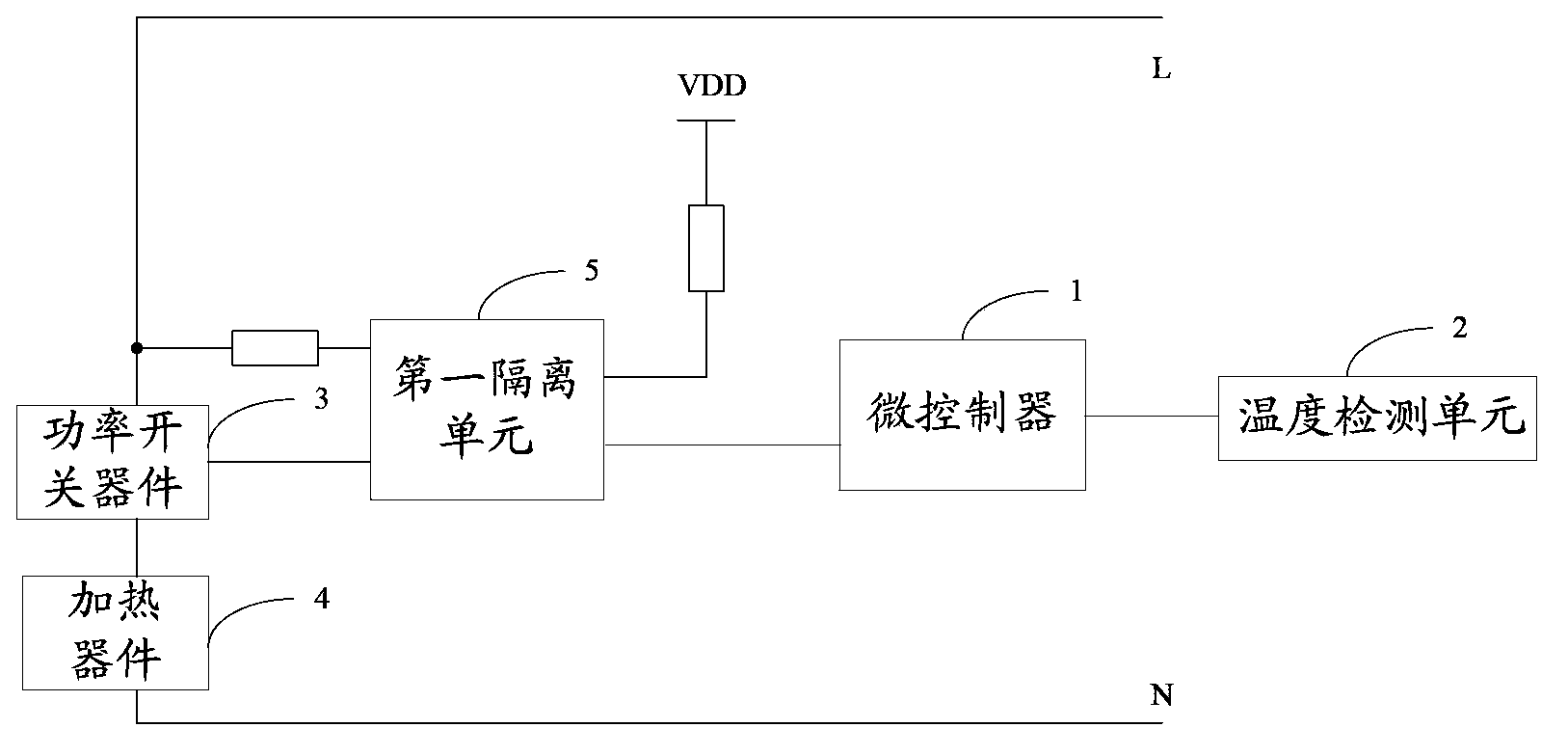

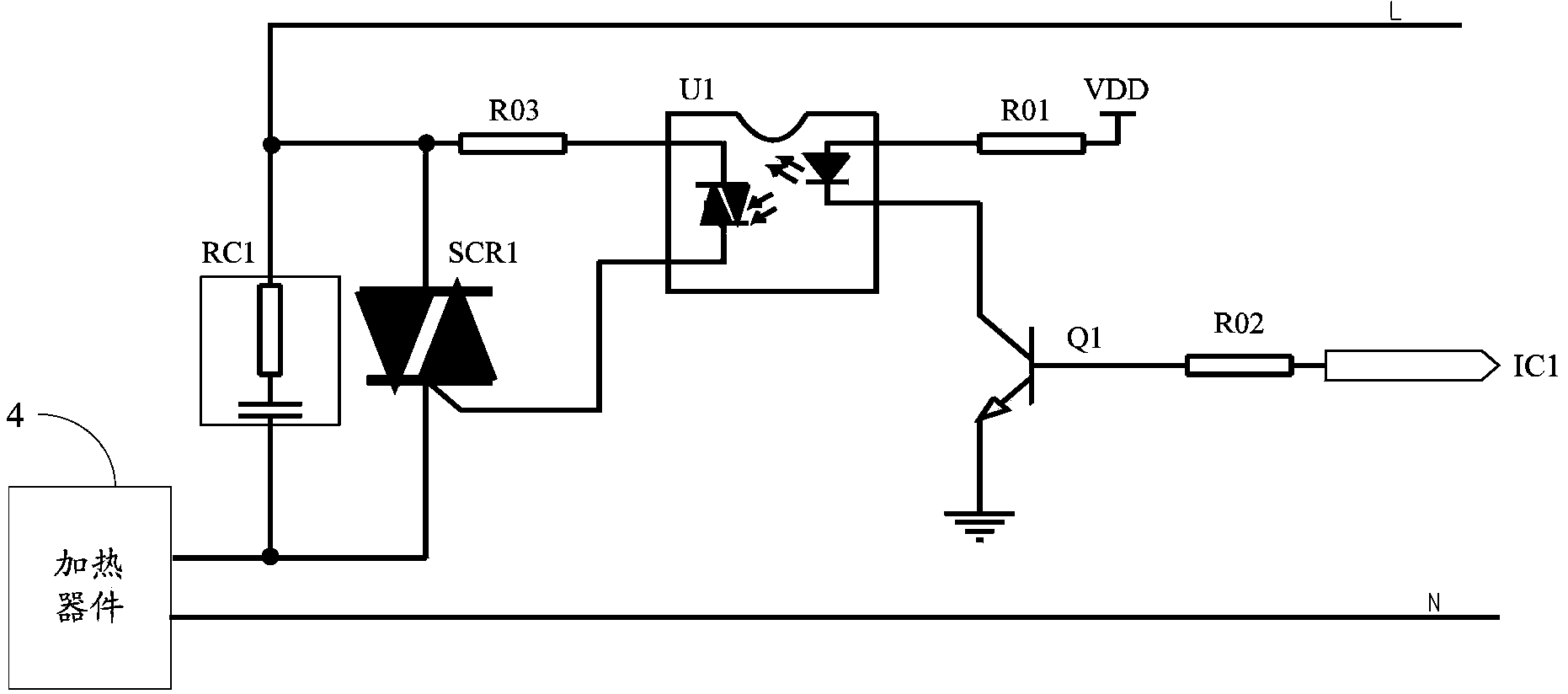

[0051] The embodiment of the present application provides a disinfection cabinet power control device and method, wherein the disinfection power control method adopts a variable power staged control method to control the heating power of the heating device. The first preset power continues to heat, so that the temperature in the high-temperature disinfection chamber rises rapidly, thereby shortening the heating time of the disinfection cabinet; in the second stage, when the temperature in the high-temperature disinfection chamber rises to the first preset temperature (for example, high temperature When the temperature of the disinfection point is 120°C), use a smaller second preset power (such as 300W-400W) for heating, so that the temperature in the high-temperature disinfection chamber will slowly rise to the second preset temperature (such as 130°C) to ensure the disinfection ability In the third stage, the heating power is further reduced to keep the temperature in the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com