High temperature furnace slag sensible heat power generating method

A technology of thermal power generation and slag, which is applied in the direction of machines/engines, improvement of process efficiency, ceramic extrusion dies, etc., can solve the problems of low utilization rate of wet energy, uneconomical technology, and few practical applications, etc., to achieve the improvement of slag Sensible heat utilization rate, realization of cascade utilization, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

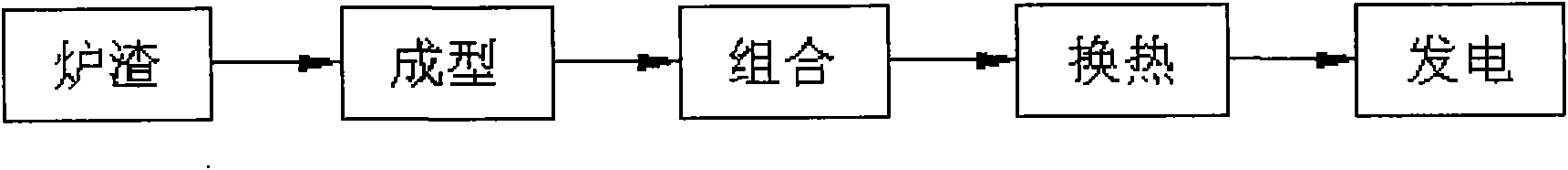

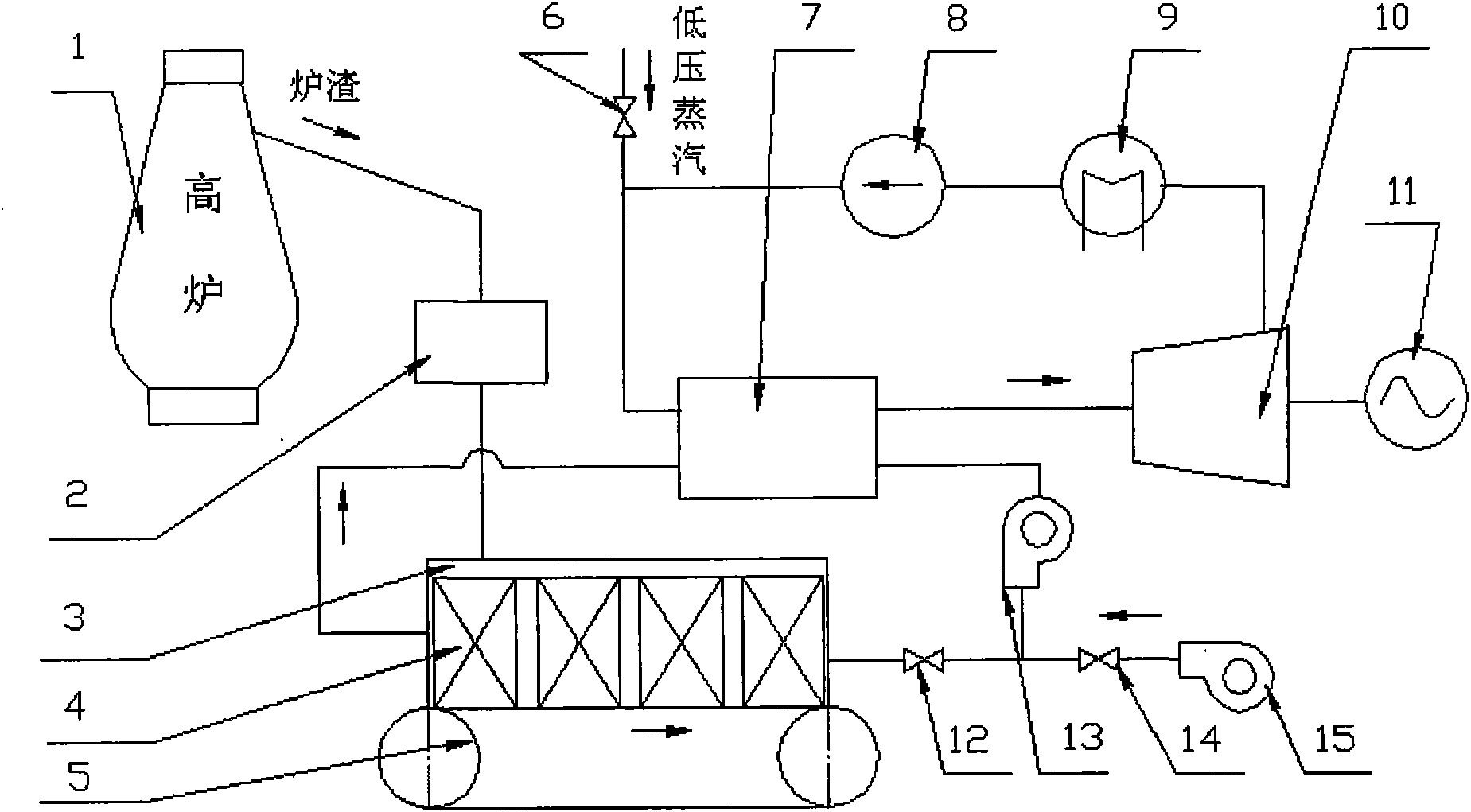

[0032] figure 2 It is a specific embodiment of the high-temperature slag sensible heat power generation method of the present invention.

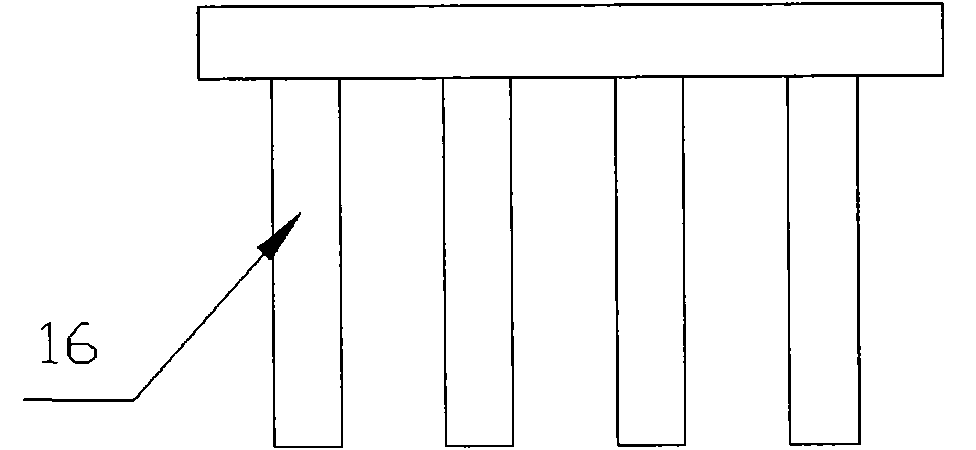

[0033] Sensible heat generation of high temperature slag of the present invention such as figure 2 As shown, the power generation system consists of blast furnace 1, pressing device 2, adiabatic furnace 3, slag checker brick 4, chain machine 5, valve 6, waste heat boiler 7, circulation pump 8, condenser 9, steam turbine 10, generator 11, Valve 12, circulation fan 13, valve 14 and blower fan 15 constitute. The high-temperature slag generated by the blast furnace 1 with a temperature of 1300-1450°C is pressed by the cylinder 16 of the upper mold of the pressing device 2 into such Figure 4 The slag checker brick shown in 4.

[0034] Place the slag checker bricks 4 in the channel 18, channel 19 or channel 20 of the adiabatic furnace 3 in sequence, and the low-temperature flue gas enters the channel 18, channel 19 or 20 of the adiabatic fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com