Ultrasonic calorimeter capable of detecting content of heavy metals and filtering impurities

A heavy metal and ultrasonic technology, applied in the field of ultrasonic heat meters, can solve the problems of inability to measure the content of heavy metals in water and filter impurities, and achieve the effect of ensuring normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

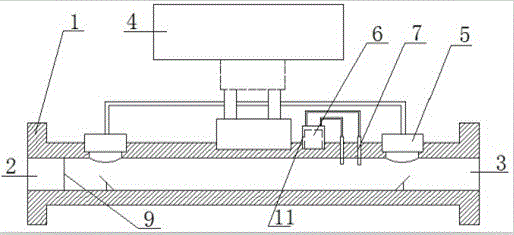

[0013] Such as figure 1 As shown, this embodiment provides an ultrasonic calorimeter for detecting heavy metal content and filtering impurities, including a meter body 4, a copper tube 1, a transducer 5 on the copper tube 1 and water inlets 2 at both ends of the copper tube 1 and the water outlet 3, between the meter body 4 and the transducer 5, a placement chamber 11 for a heavy metal detector 6 is arranged on the copper pipe 1 close to the water outlet 3, and the placement chamber 11 and the copper pipe 1 are welded Fixedly connected, a probe of a heavy metal detector 6 is arranged between the placement cavity 11 and the transducer 5 . When people need to detect the heavy metal content in water, they can use the heavy metal detector on the ultrasonic heat meter to observe the data, and take measures to protect the copper pipe in time.

Embodiment 2

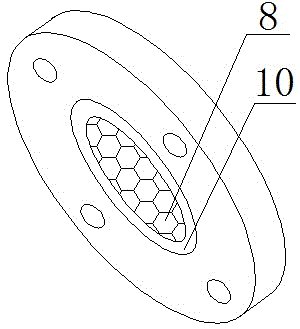

[0015] Such as figure 1 with figure 2 As shown, in this embodiment, on the basis of Embodiment 1, a high temperature resistant filter screen-8 is provided at the nozzle 10 of the water inlet 2, and a high temperature resistant filter is built in the copper pipe 1 between the transducer 5 and the water inlet 2. Filter two 9. The filter screen in the copper pipe can block some impurities. Because the diameter of the filter screen is large, it will not have a great impact on the water flow velocity. In addition, the filter screen is provided with a layer at the nozzle and the copper pipe, which can be used in Under the premise of not affecting the water flow speed, the impurities contained in the water are filtered out to ensure the normal use of the ultrasonic heat meter.

[0016] The invention solves the problem that the existing ultrasonic heat meter cannot measure the heavy metal content in water and filter impurities. When people need to detect the heavy metal content in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com