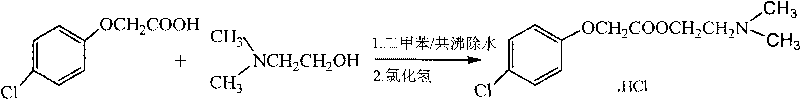

Method for preparing meclofenoxate hydrochloride sterile bulk drug

The technology of meclofenxe hydrochloride and raw material medicine is applied in the field of preparation of aseptic raw material medicine of central stimulant meclofen axetil hydrochloride, and can solve the problems of easy hydrolysis of the raw material of meclofen axetil hydrochloride of filter, easy blockage of pipelines and the like, Achieve the effect of low cost, stable process and low moisture content of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In the reflux reaction device, add accurately weighed 1 kg of non-sterile meclofenoxate hydrochloride and 15 L of isopropanol, stir, heat and reflux until completely dissolved, add 50 g of medicinal activated carbon, decolorize under reflux for 15 minutes, and pass through 0.45 μm Coarse filtration with a microporous membrane, and sterile filtration with a 0.25 μm microporous membrane; the resulting filtrate was concentrated under reduced pressure at 50°C to a volume of about 4L, then stood for crystallization, filtered, and dried under reduced pressure at 50°C to obtain 938.9g of the product , the moisture content is 0.25%, and the yield is 93.9%.

Embodiment 2

[0019] In the reflux reaction device, add accurately weighed 1kg of non-sterile meclofenoxate hydrochloride and 12L of isopropanol, stir, heat and reflux until completely dissolved, add 25g of medicinal activated carbon, decolorize under reflux for 30 minutes, and pass through 0.45μm Coarse filtration with a microporous membrane, and sterile filtration with a 0.25 μm microporous membrane; the resulting filtrate was concentrated under reduced pressure at 50°C to a volume of about 3L, then stood for crystallization, filtered, and dried under reduced pressure at 50°C to obtain 922.6g of the product , the moisture is 0.19%, and the yield is 92.3%.

Embodiment 3

[0021] In the reflux reaction device, add accurately weighed 1kg of non-sterile meclofenoxate hydrochloride and 10L of isopropanol, stir, heat and reflux until completely dissolved, add 100g of medicinal activated carbon, decolorize under reflux for 25 minutes, and pass through 0.45μm Coarse filtration with a microporous membrane, and sterile filtration with a 0.25 μm microporous membrane; the resulting filtrate was concentrated under reduced pressure at 50°C to a volume of about 4L, then stood for crystallization, filtered, and dried under reduced pressure at 50°C to obtain 917.1g of the product , the moisture is 0.33%, and the yield is 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com