Patents

Literature

31results about How to "Fast pressurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite structured adsorbents

InactiveUS20080148936A1Lower overall pressure dropReduce power consumptionGas treatmentIsotope separationVacuum pressureSorbent

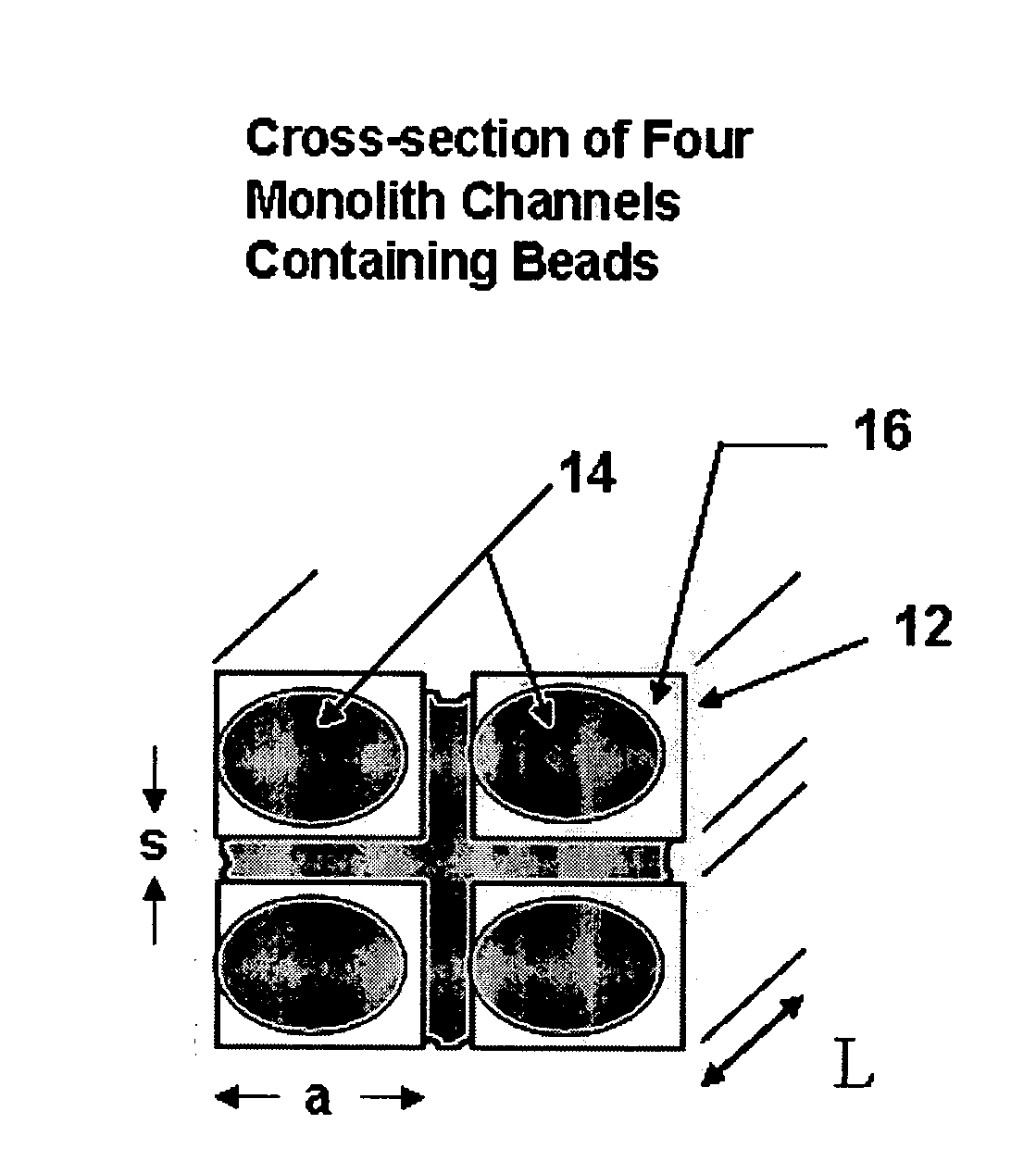

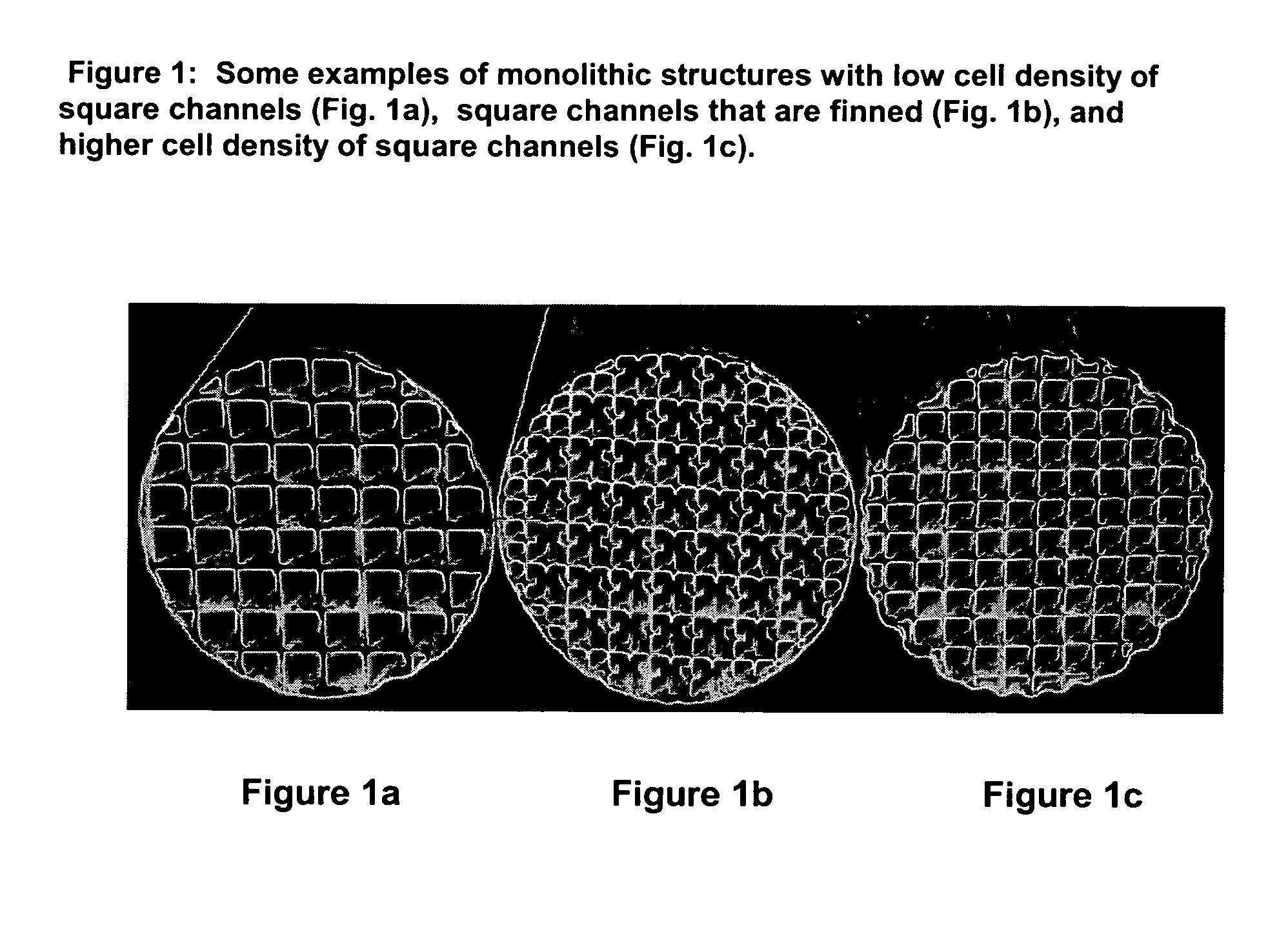

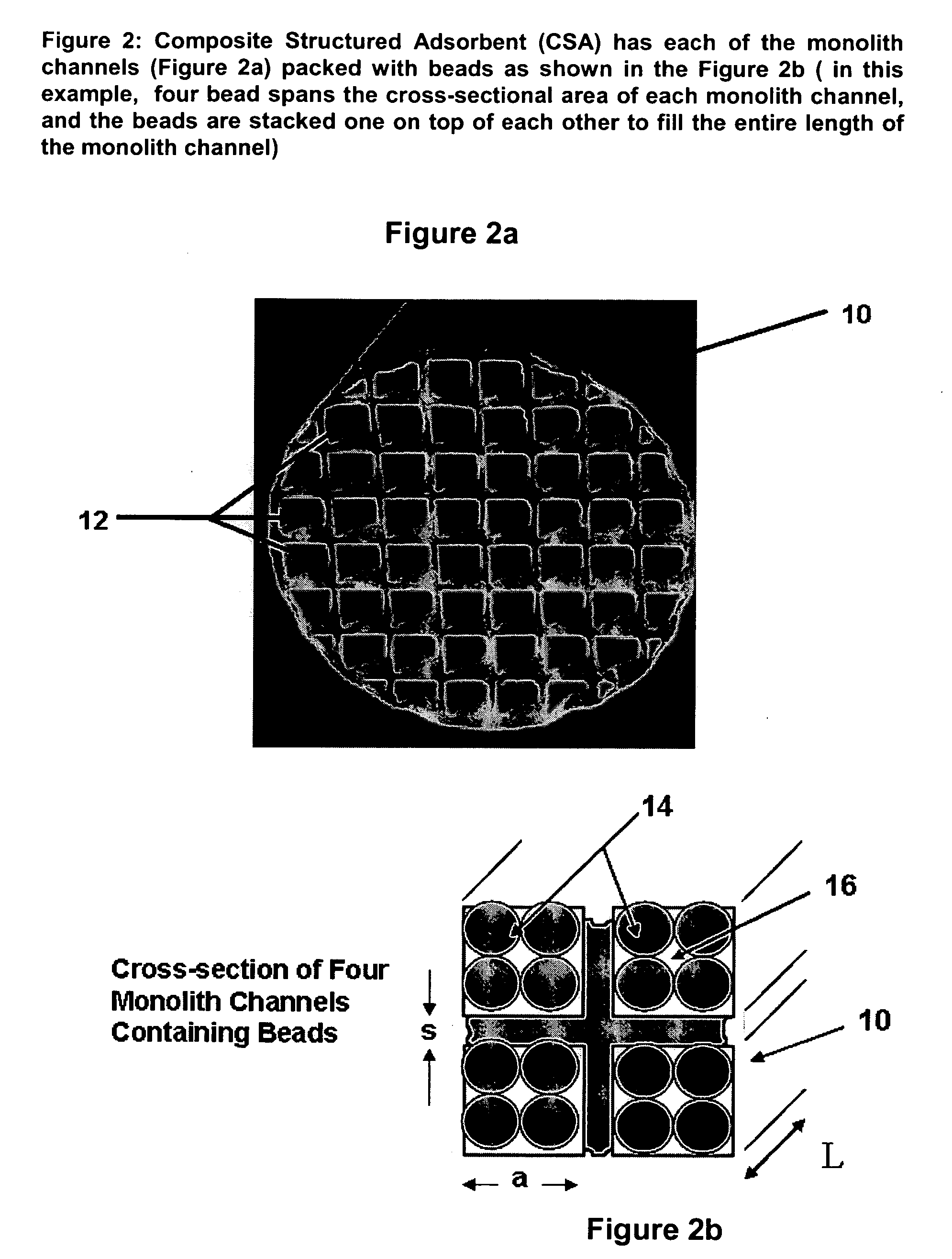

The present invention relates to composite structured adsorbents and methods of use therefor. The invention more particularly relates to composite structured adsorbents that can include a multi-channel framework (e.g., monoliths), the channels of the multi-channel framework containing adsorbent beads particles therein, with a channel-to-particle diameter ratio in the range of 1 to 10, more preferably 1 to 7 and even more preferably 1 to 5. In the case of non-spherical particles, the hydraulic diameter is used in the calculation of the channel-to-particle diameter. The composite structured adsorbents of the present invention can be used in various industrial applications, for example in pressure swing adsorption (PSA) or vacuum pressure swing adsorption (VPSA) processes to produce O2 from air.

Owner:PRAXAIR TECH INC

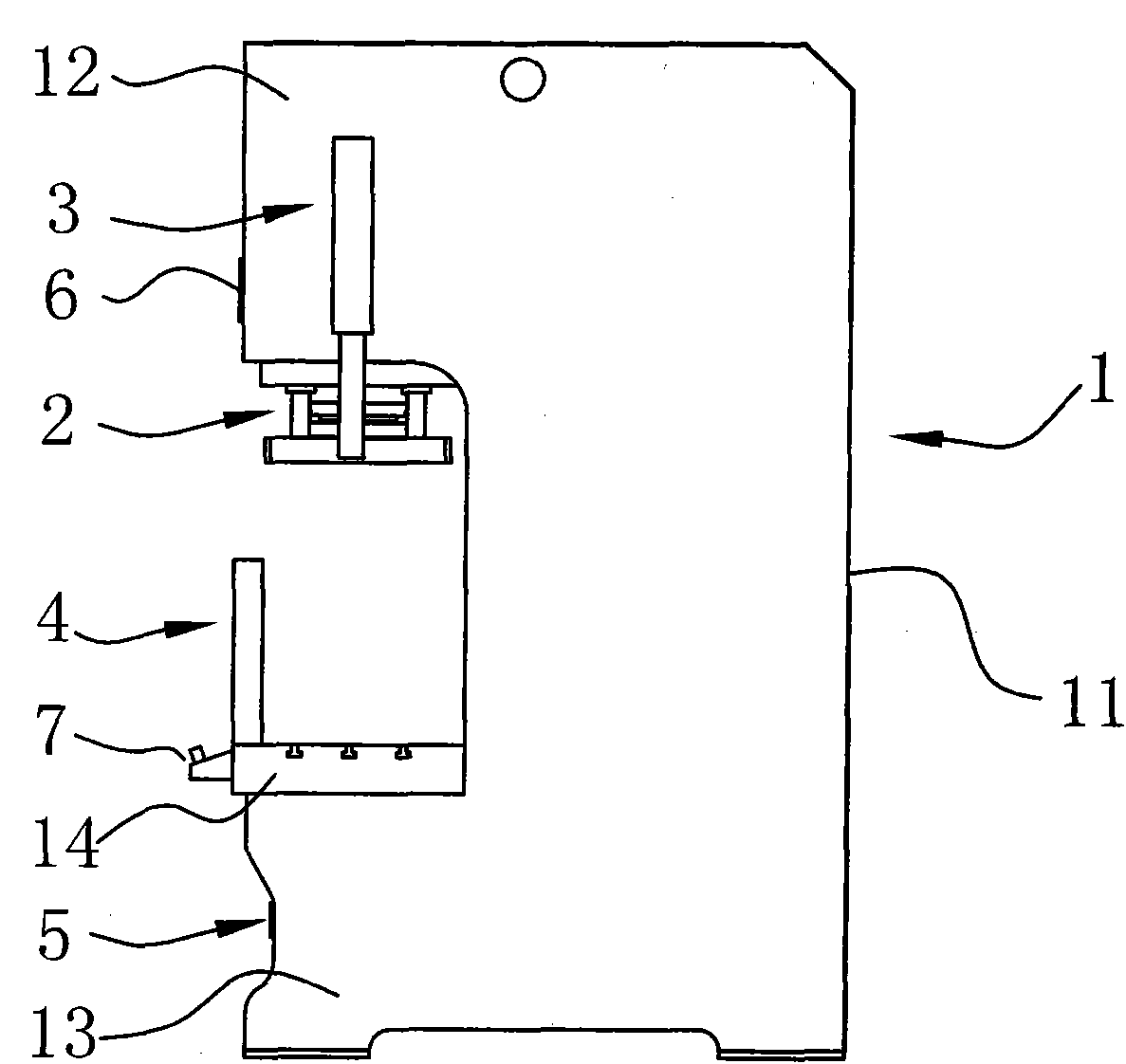

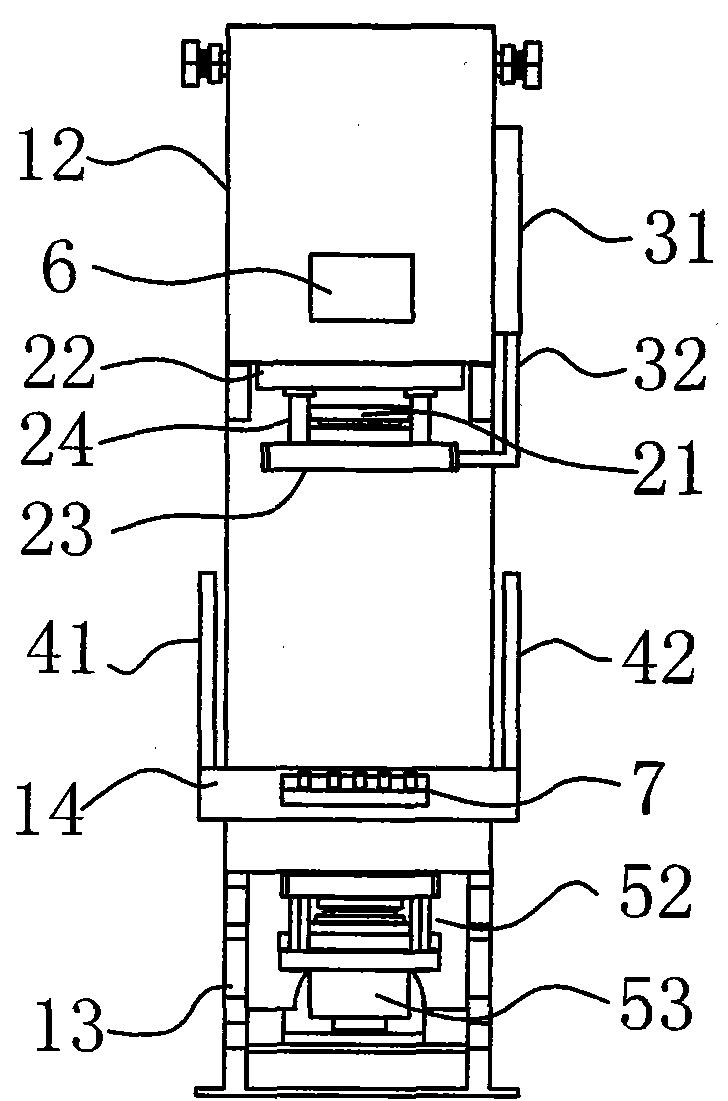

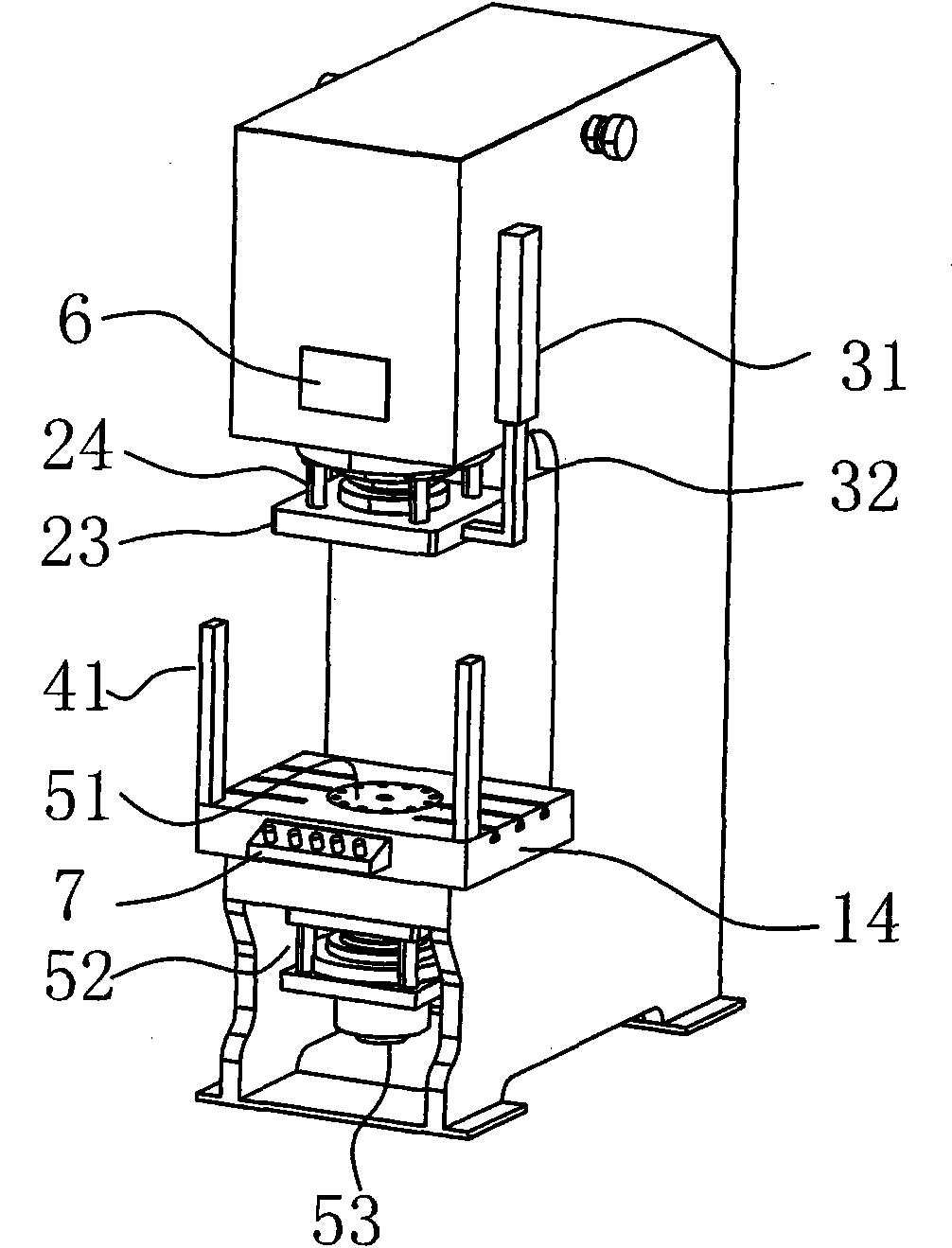

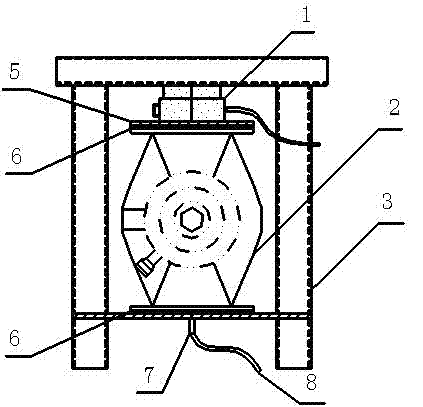

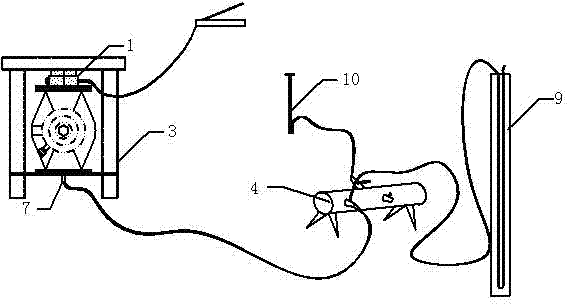

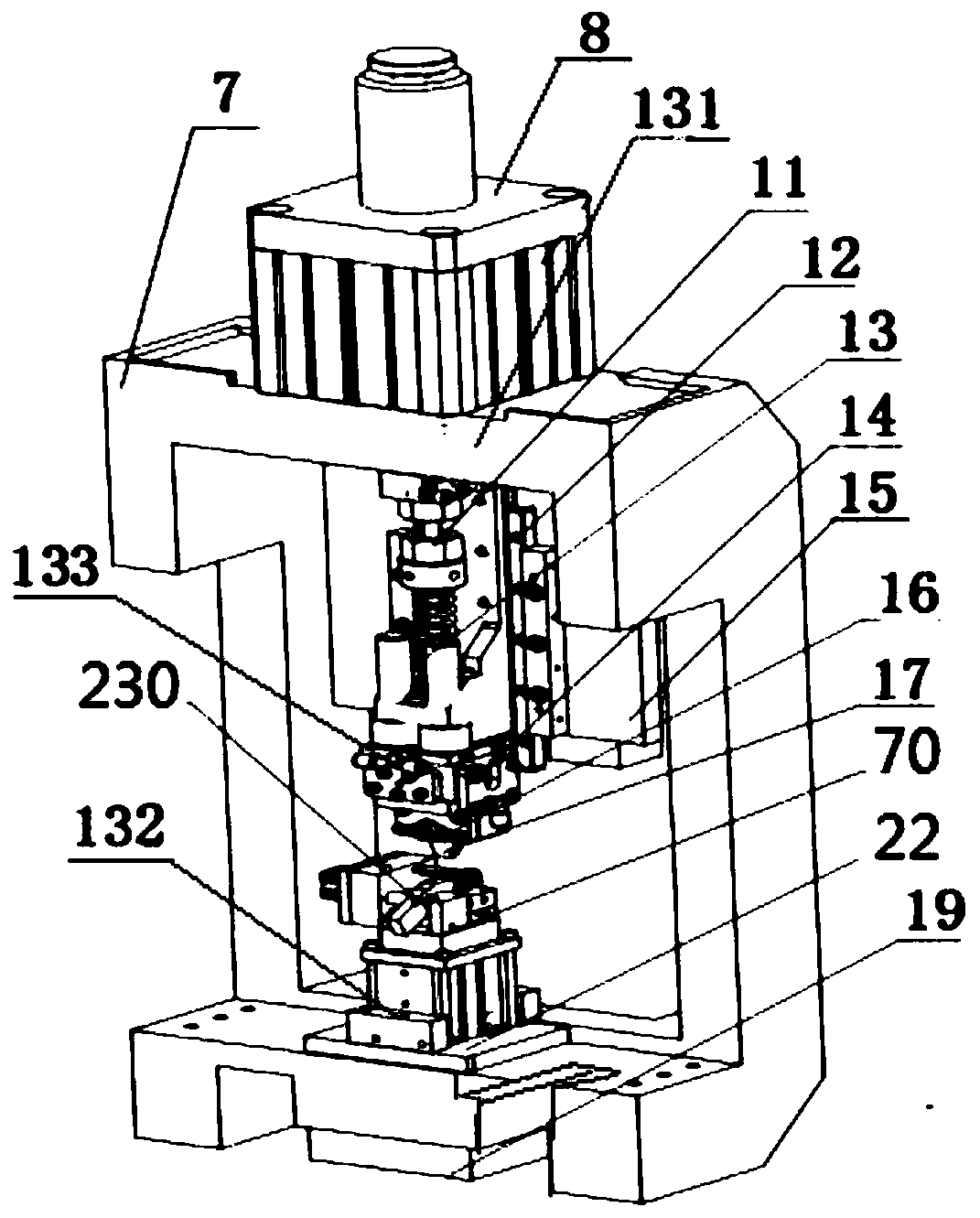

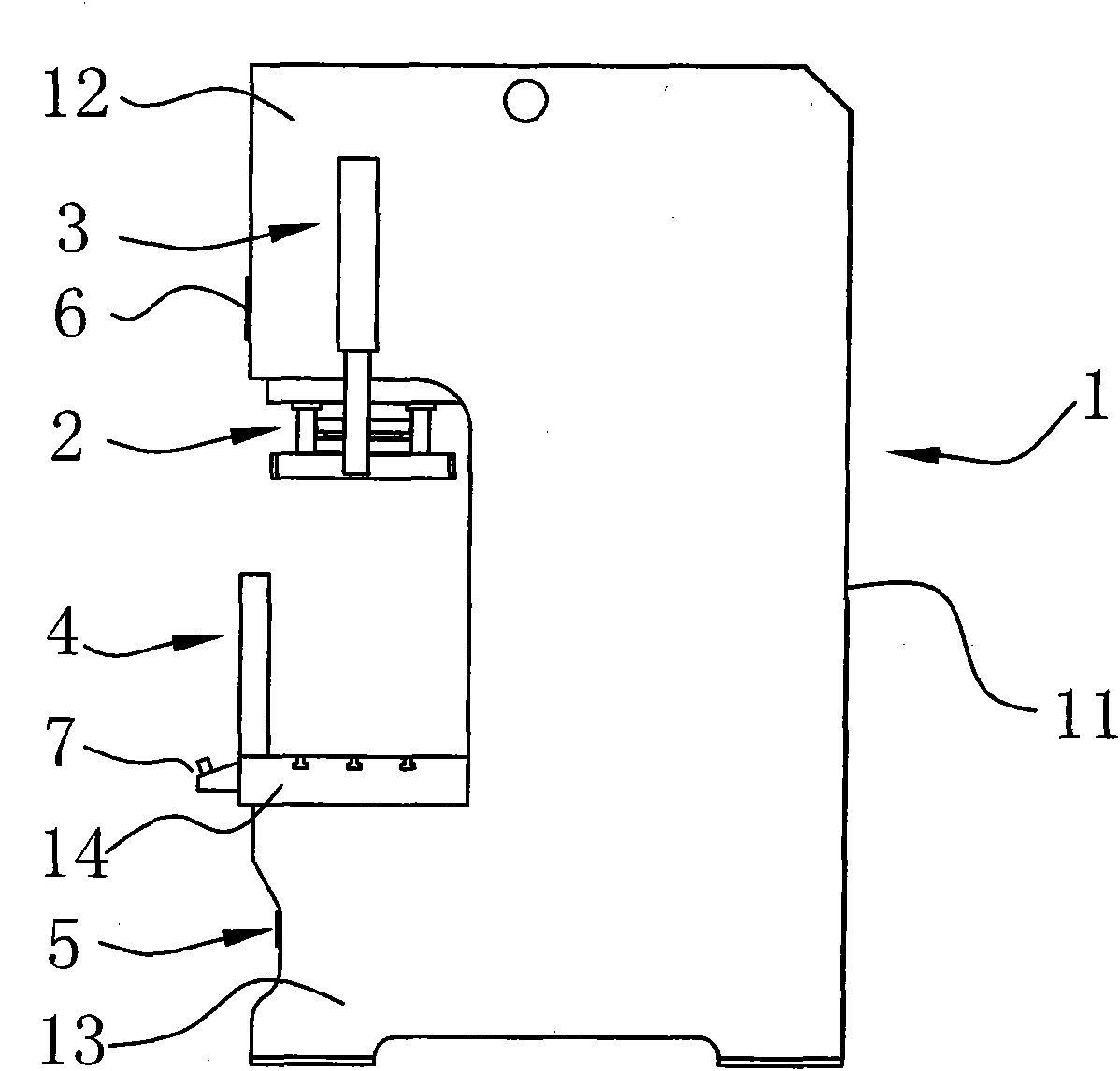

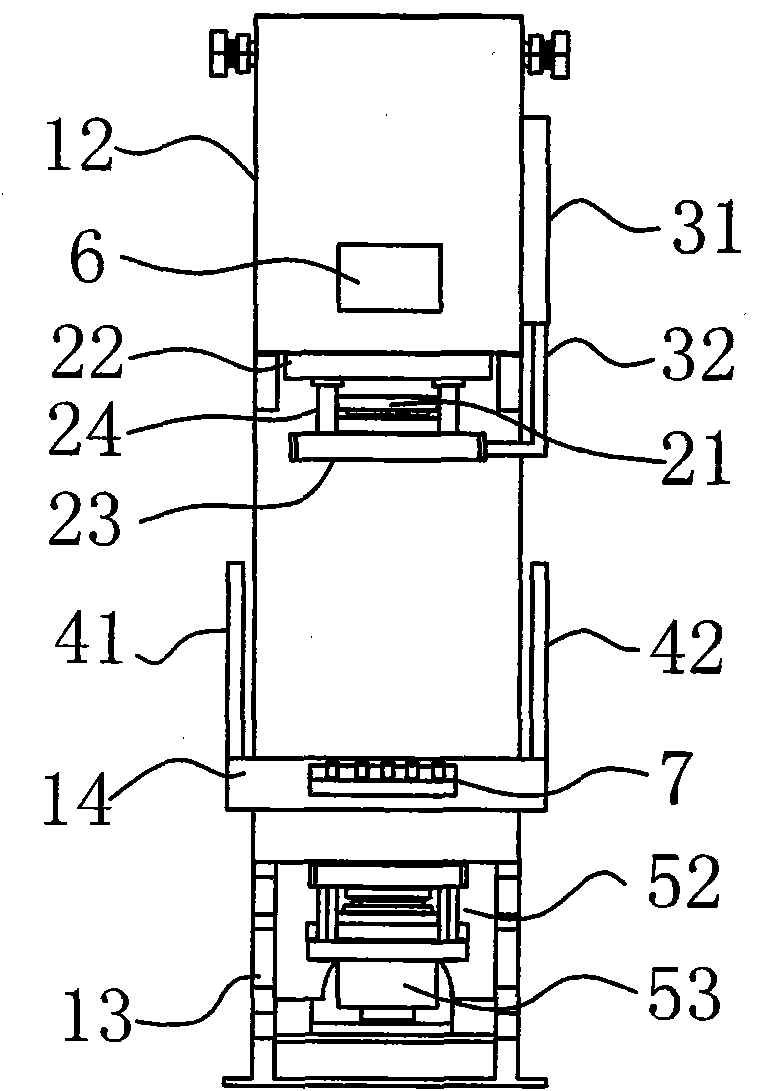

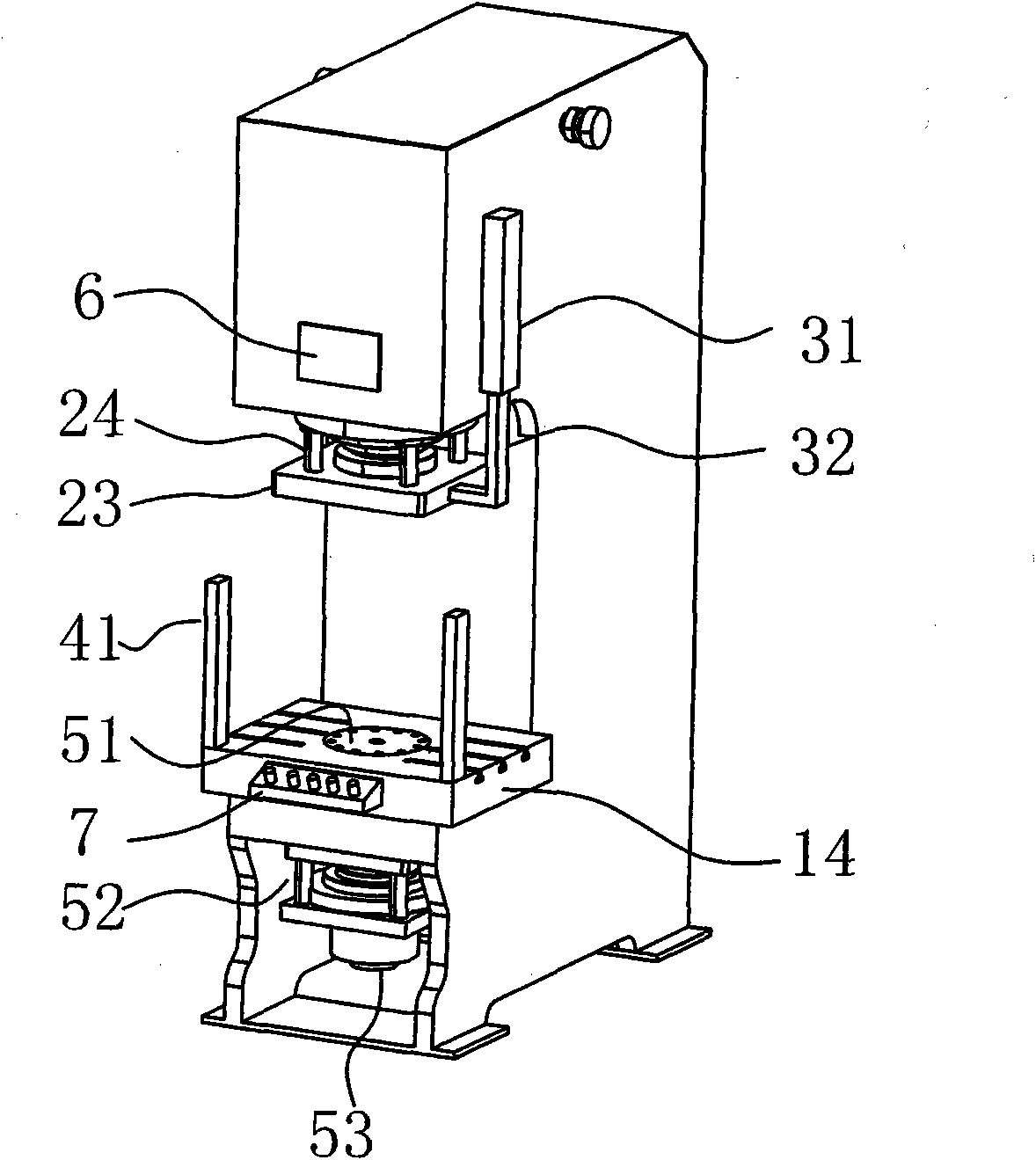

Servo electrohydraulic composite pressure method and press machine thereof

InactiveCN101927578AImprove performanceReduce energy consumptionPress ramNumerical controlPunch press

The invention discloses a servo electrohydraulic composite pressure method, comprising the following steps: 1) arranging a stander; 2) arranging an upper hydraulic device on the stander, 3) arranging a closed ring servo electrohydraulic control system, wherein the closed ring servo electrohydraulic control system is connected with the upper hydraulic device, and controls the work situation of the upper hydraulic device; the invention further discloses a press machine which implements the method; the method provided by the invention uses a servo electrohydraulic technology to replace the traditional electrohydraulic control technology, which has simple manufacturing, high efficiency, little power consumption and high control precision; the position control precision can reach to 0.01 to 0.02 millimeters; the pressing, the tensioning, the de-molding, the full deciding and other functions can be realized simultaneously, so the method has a comparatively high processing flexibility; the press machine provided by the invention is rational in structure, little in volume, stable in work, high in capacity, little in noise, and wide in application range. The advantages of a mechanical punching machine, a hydraulic punching machine and a numerical control are integrated, so the press machine has the advantages of multi-function, low cost, large pressure tonnage, etc.

Owner:东莞市得力仕机械科技有限公司

WPC press

InactiveCN102275324AEasy and flexible operationFast pressurizationShaping pressMaster cylinderEconomic benefits

The invention relates to a wood-plastic press, comprising a base frame, a top frame, and a column. One end of the column is fixed on the base frame, and the other end of the column is fixed to the top frame. A movable beam is strung on the column. The bottom frame is provided with a slide table, and a main oil cylinder is installed in the top frame, the bottom end of the piston in the main oil cylinder protrudes from the main oil cylinder and is connected with the movable beam located below, and the column is covered with frame, a frame oil cylinder is fixed on the movable beam, and a fast oil cylinder is fixed on the top frame. The invention is convenient and flexible in operation, operates simultaneously through a plurality of oil cylinders, has high pressurization speed, improves work efficiency, and has good economic benefits.

Owner:常熟通江机械有限公司

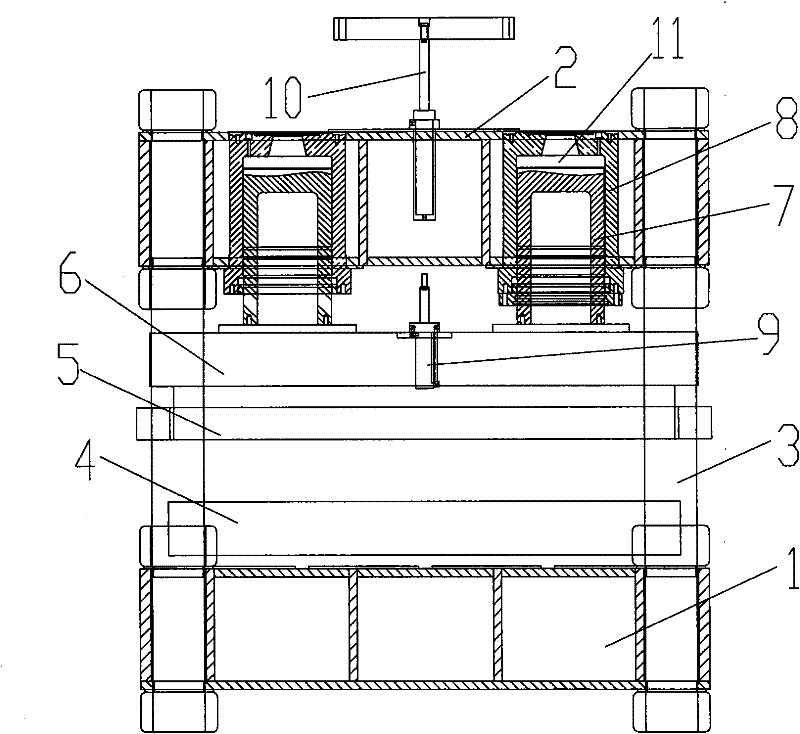

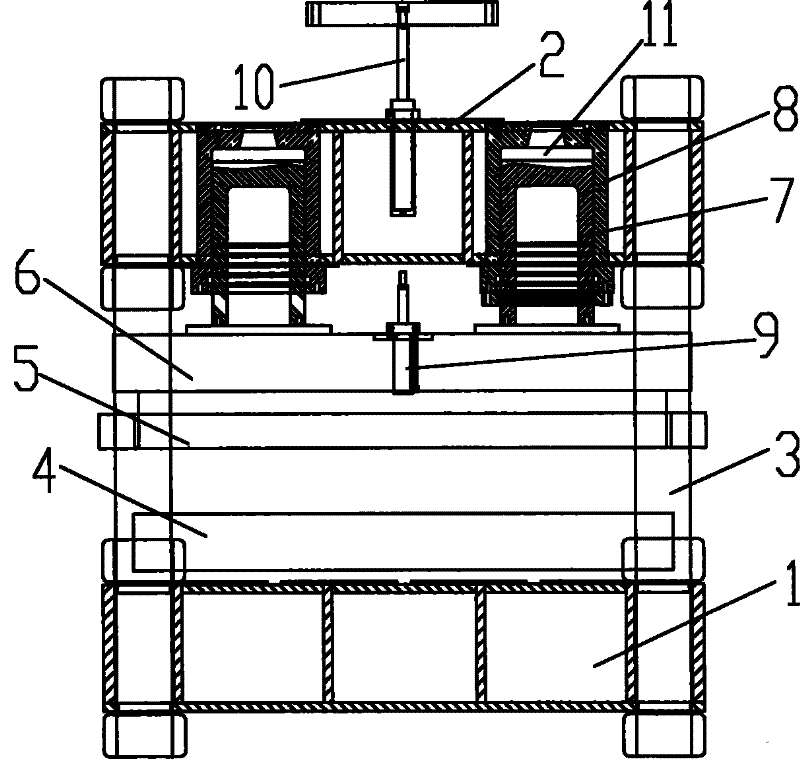

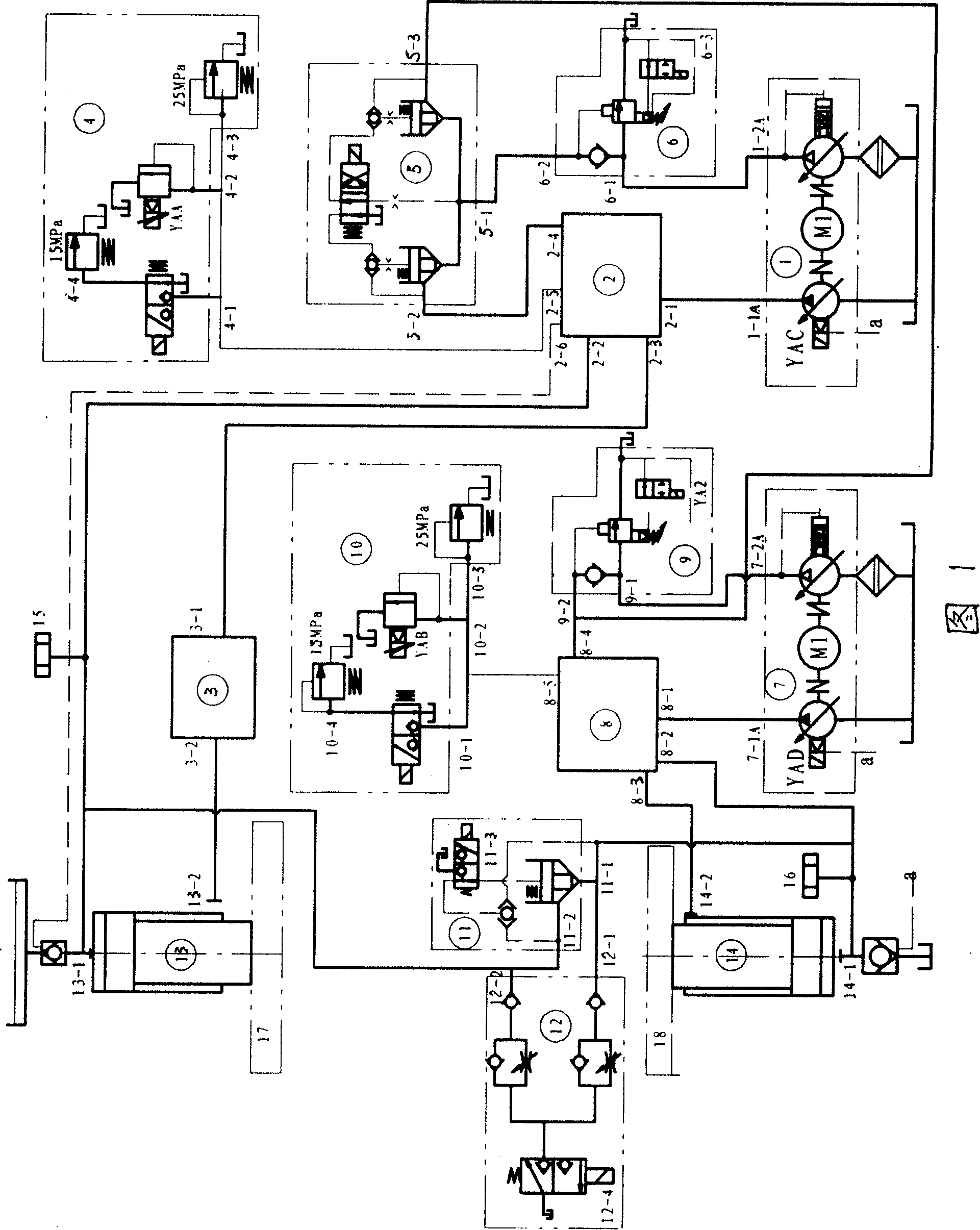

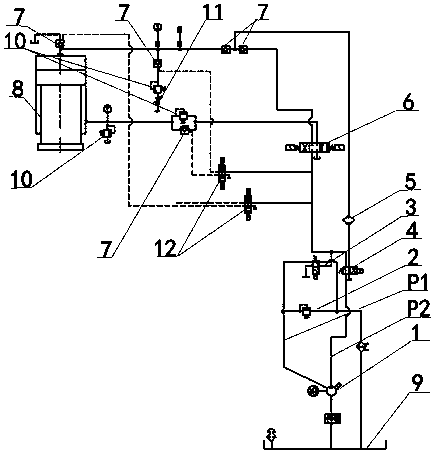

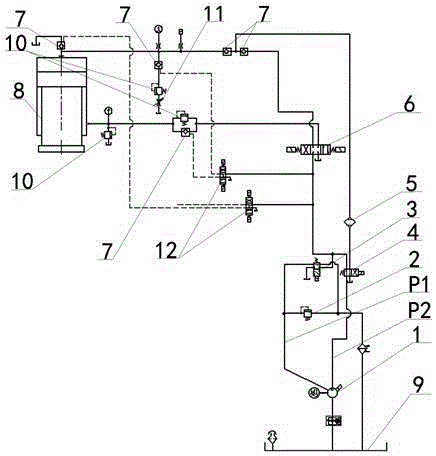

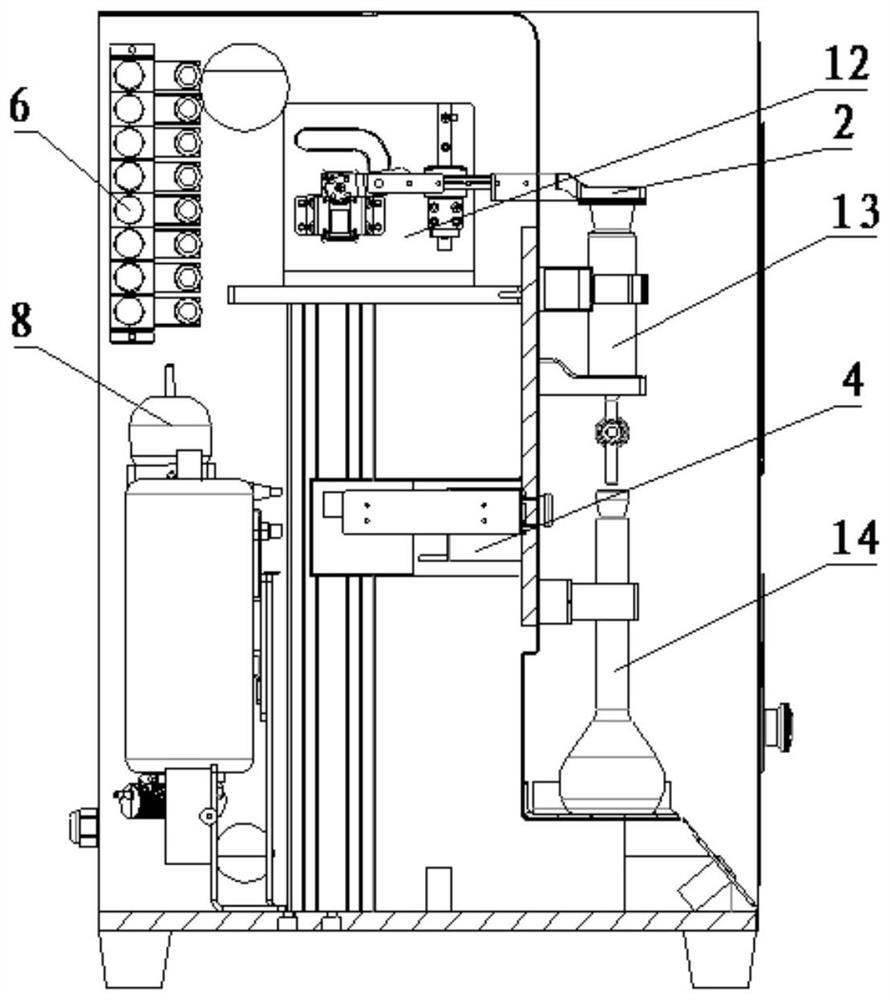

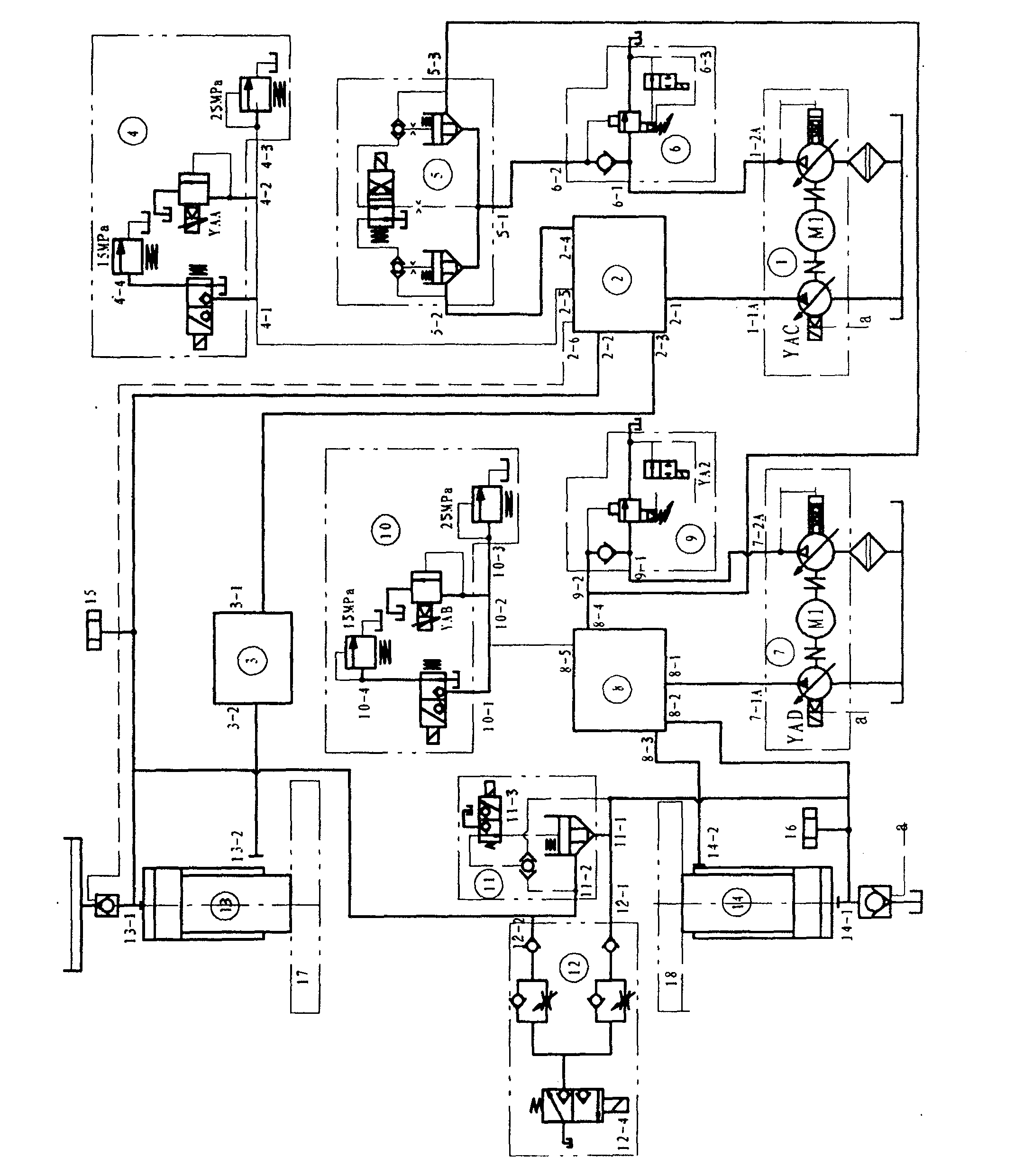

Bidirectional compression hydraulic press intelligent hydraulic control system

The present invention relates to a bidirectional pressing hydraulic machine intelligent hydraulic control system. Said system includes upper main cylinder, lower main cylinder, valve group, oil line, oil pump and oil tank. The described valve group includes upper and lower main cylinder proportion pump group, upper and lower main cylinder pump outlet valve group, supporting valve group, upper and lower main cylinder control valve group, conversion valve group, upper and lower main cylinder unloading valve group, communication valve group and unloading valve group.

Owner:TIANJIN TIANDUAN PRESS CO LTD

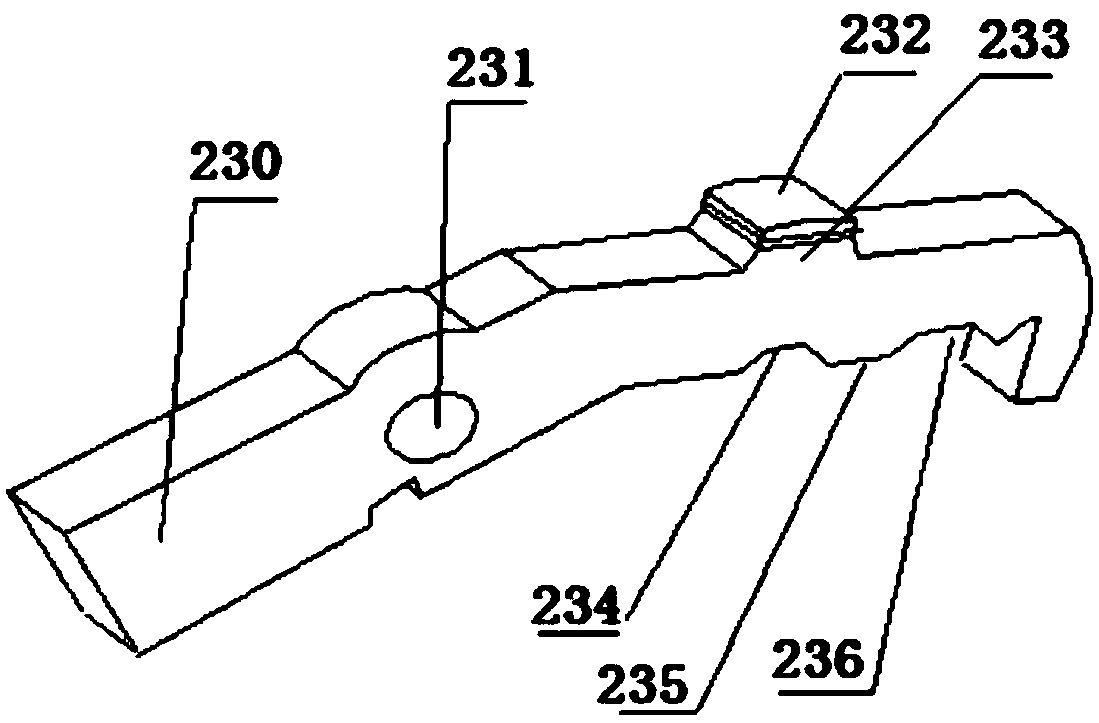

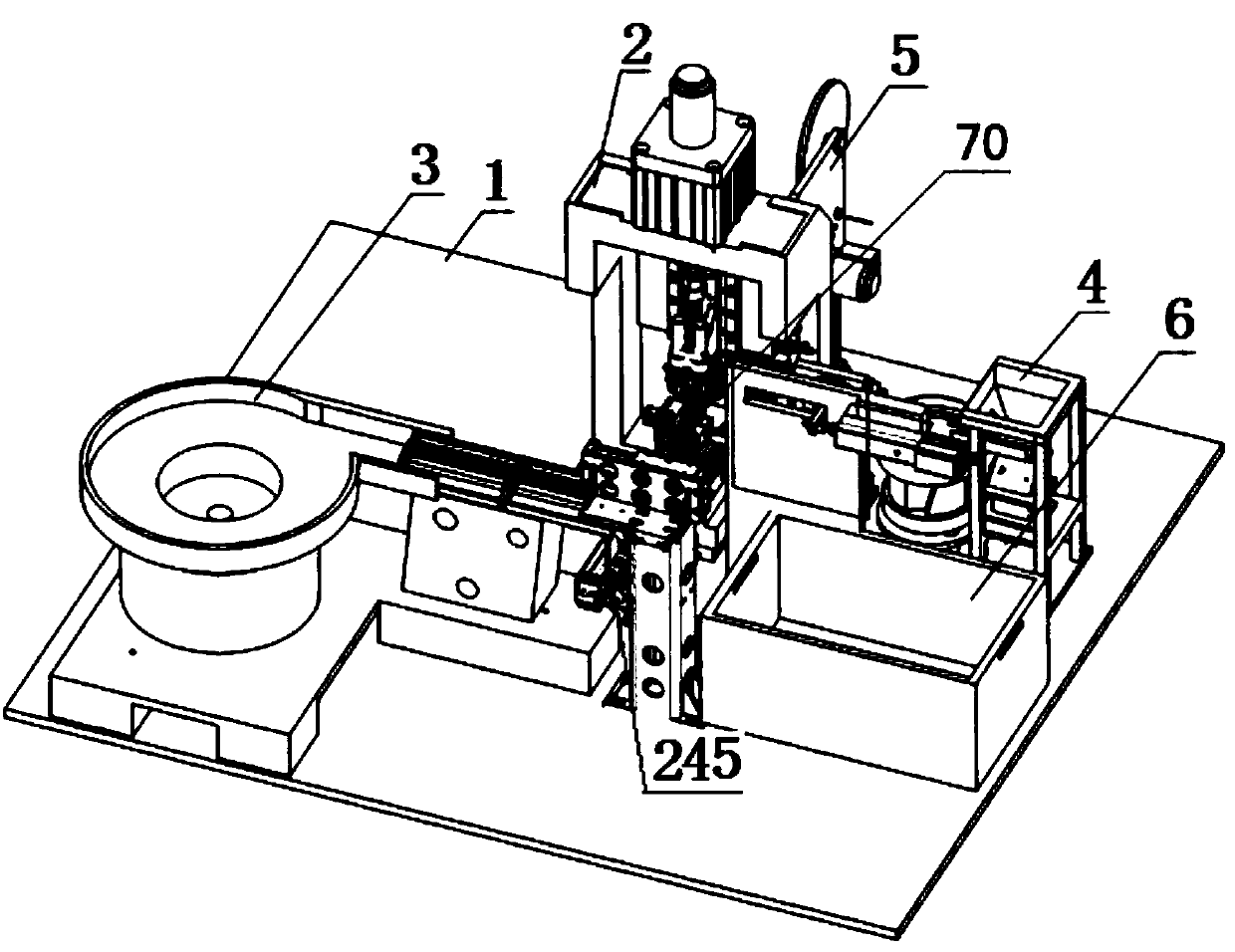

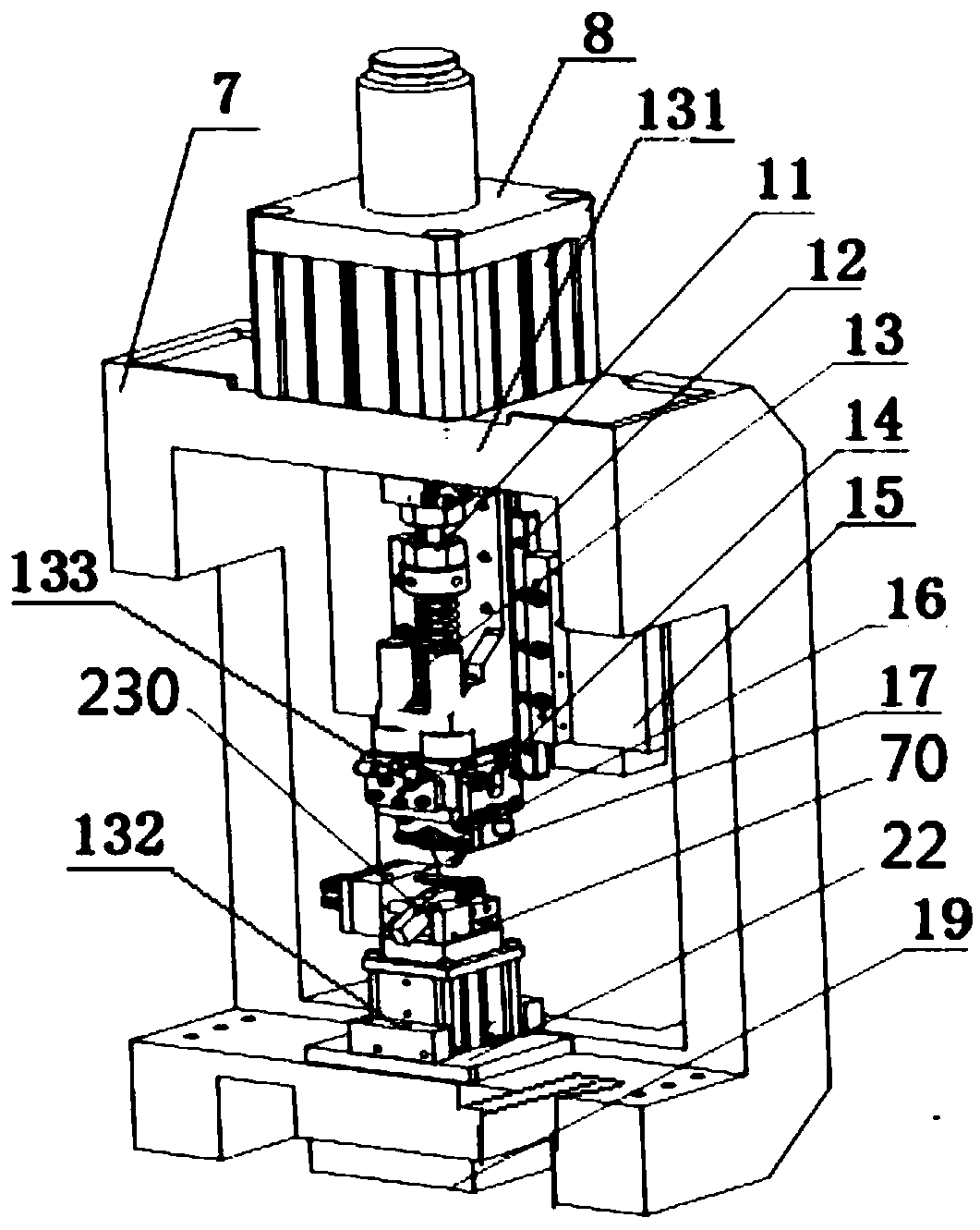

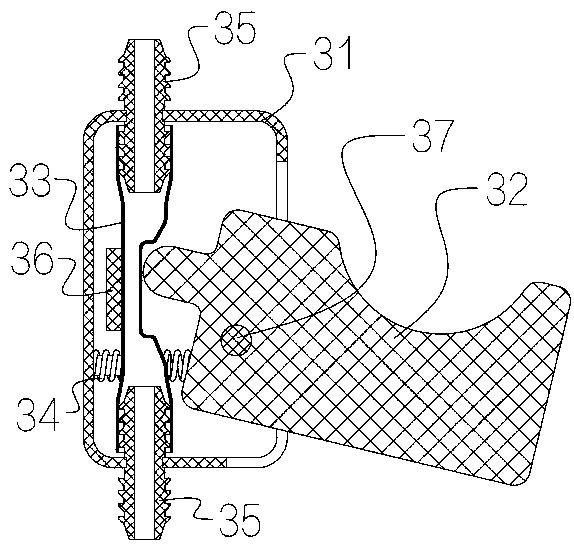

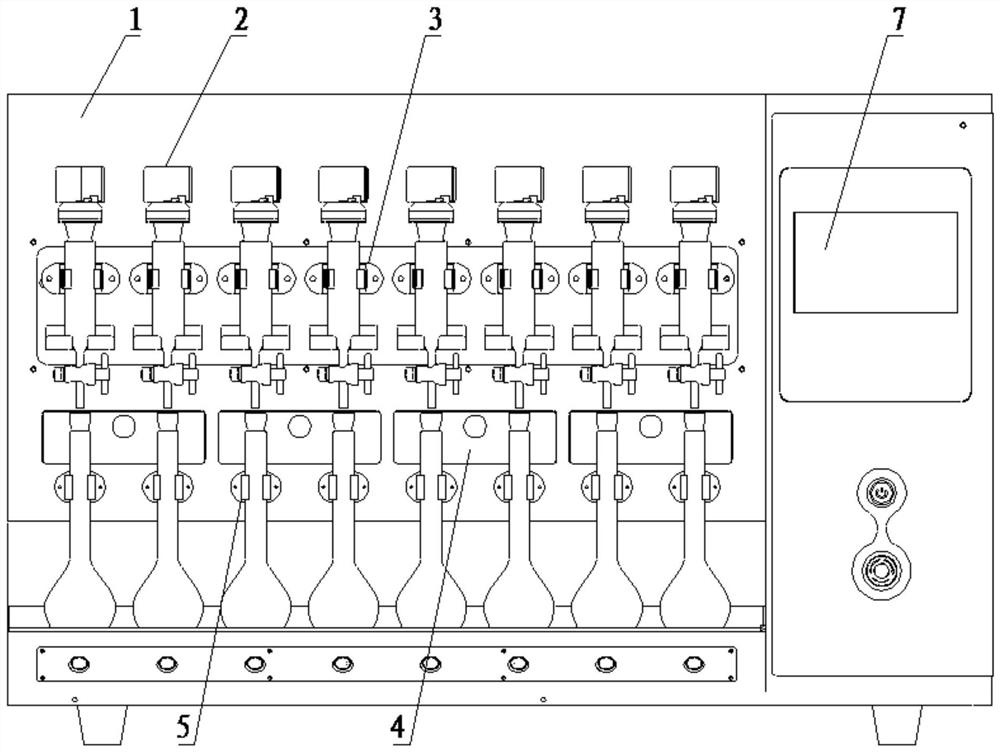

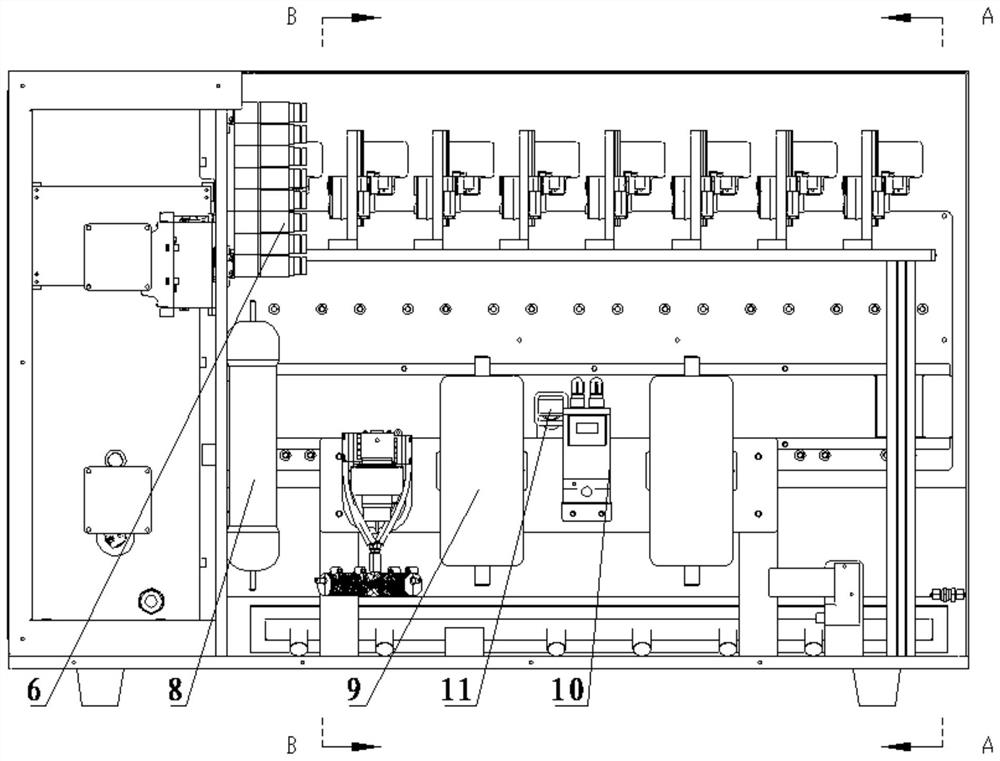

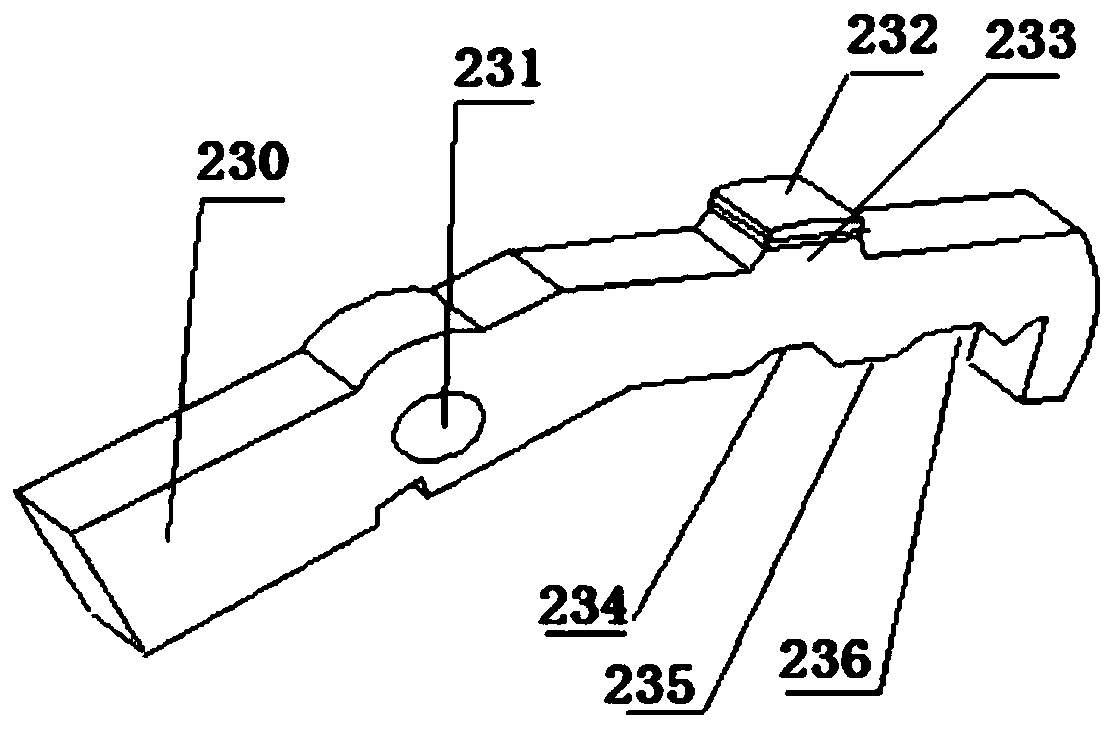

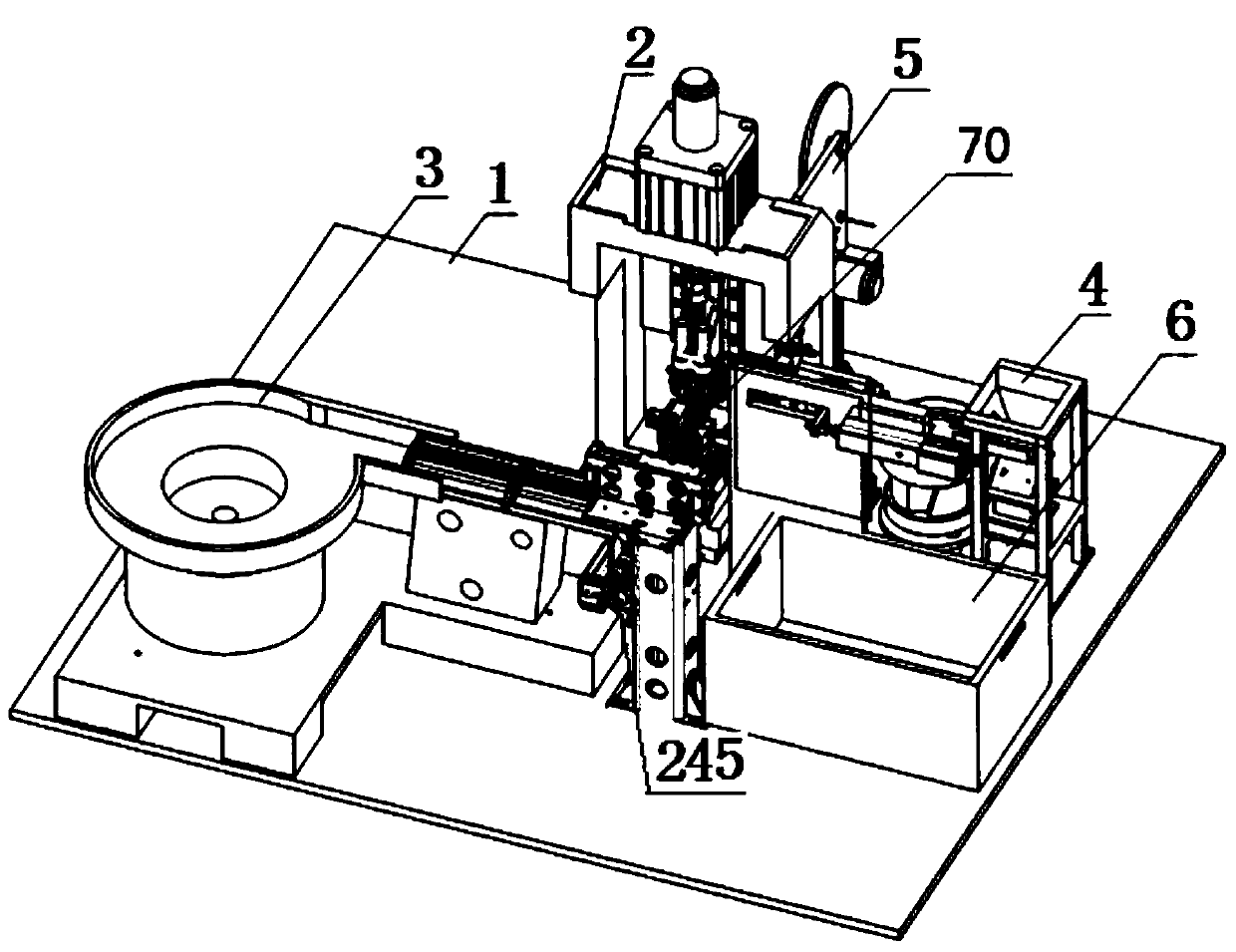

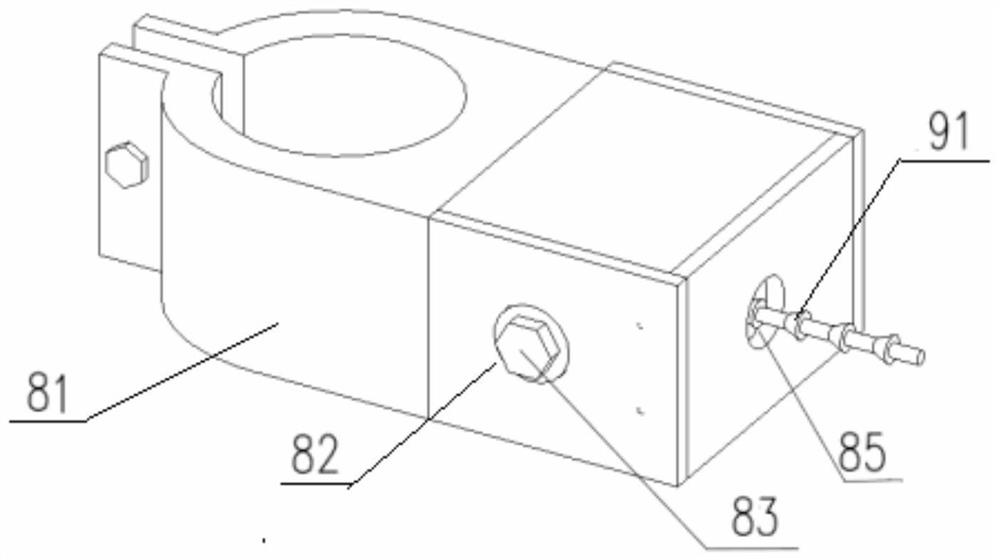

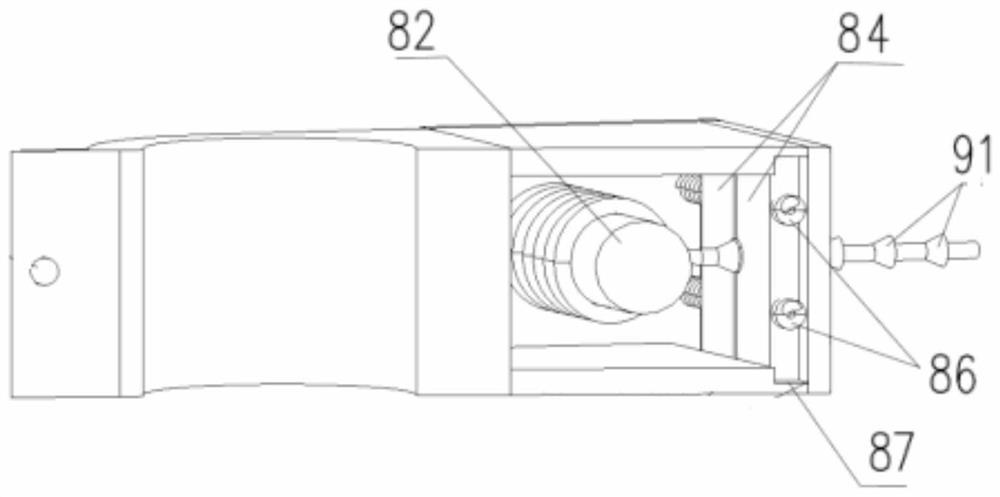

Touch tool full-automatic braze welding equipment

ActiveCN108672873AExtend your lifeLow costHeating appliancesWelding/soldering/cutting articlesEngineeringSoldering

The invention discloses touch tool full-automatic braze welding equipment. The touch tool full-automatic braze welding equipment is characterized in that a welding mechanism is arranged on a table, corresponding executing mechanisms are arranged around the welding mechanism, that is, the touch tool feeding mechanism is arranged on a first station, the soldering lug feeding mechanism is arranged ona second station, the touch spot feeding mechanism is arranged on a third station, and the discharging mechanical hand and a material box are arranged on a fourth station; the welding mechanism comprises a portal type U-shaped frame, the upper portion of the U-shaped frame is provided with a pressing unit, and an upper electrode assembly is arranged on the lower portion of the pressing unit; andthe lower portion of the U-shaped frame is provided with a suspension supporting unit. According to the touch tool full-automatic braze welding equipment, through a four-stage heating mechanism, a four-stage flexible pressurizing mechanism, a seamless pressurizing fitting mechanism and an automatic feeding mechanism, full-automatic braze welding of a touch tool and a touch spot is achieved, the welding quality is stable, the working efficiency is high, and the equipment cost is low.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

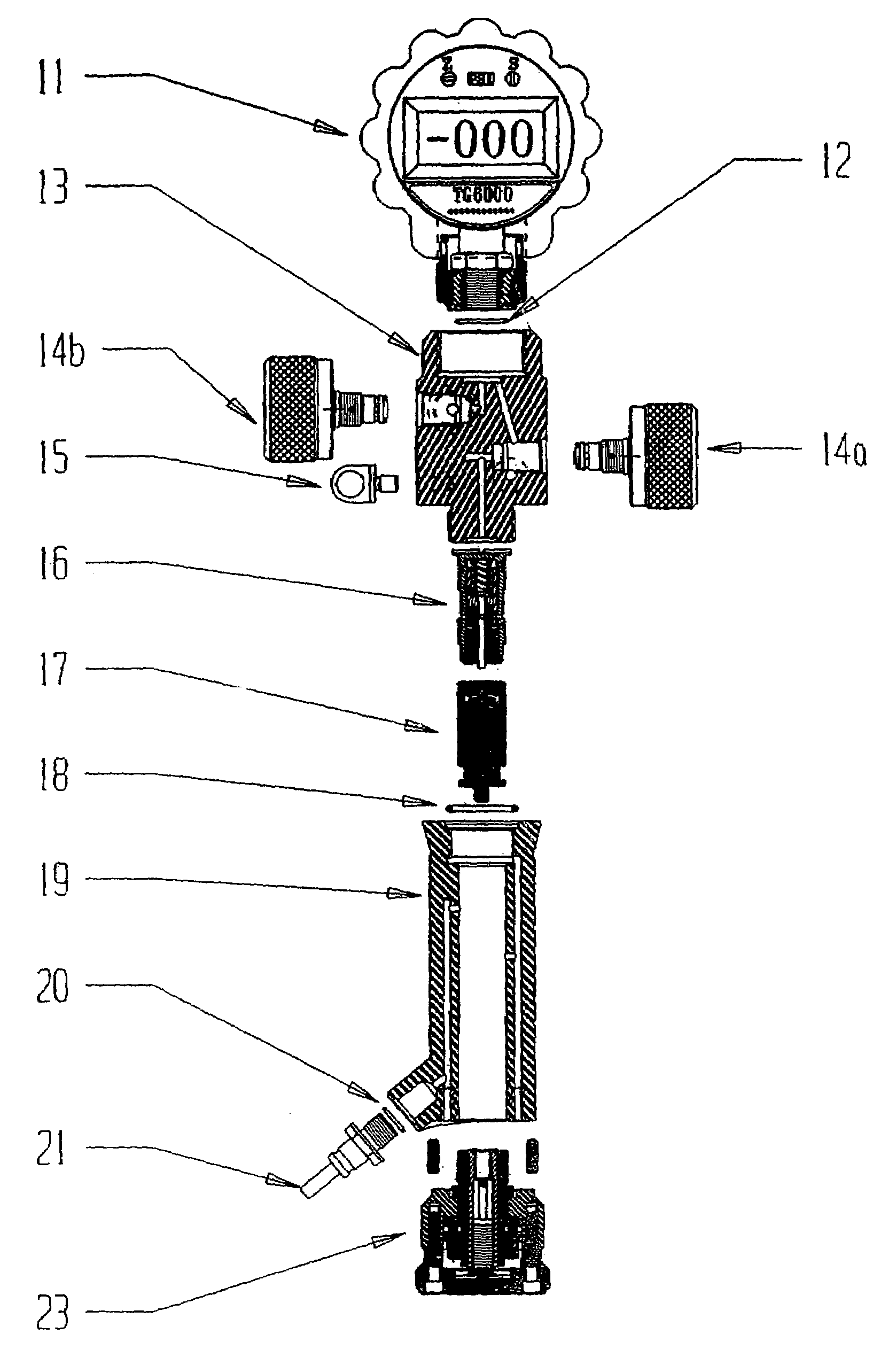

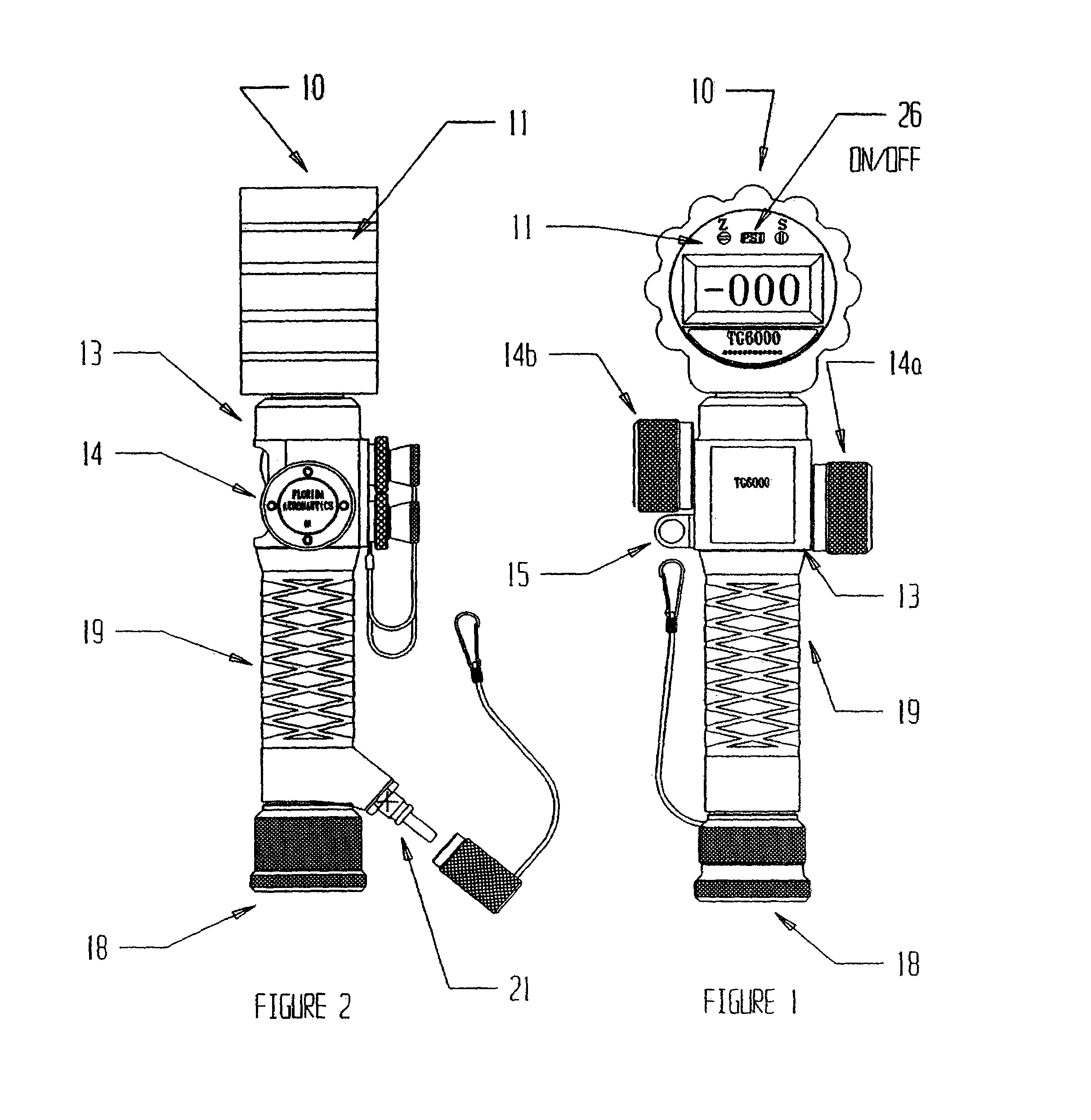

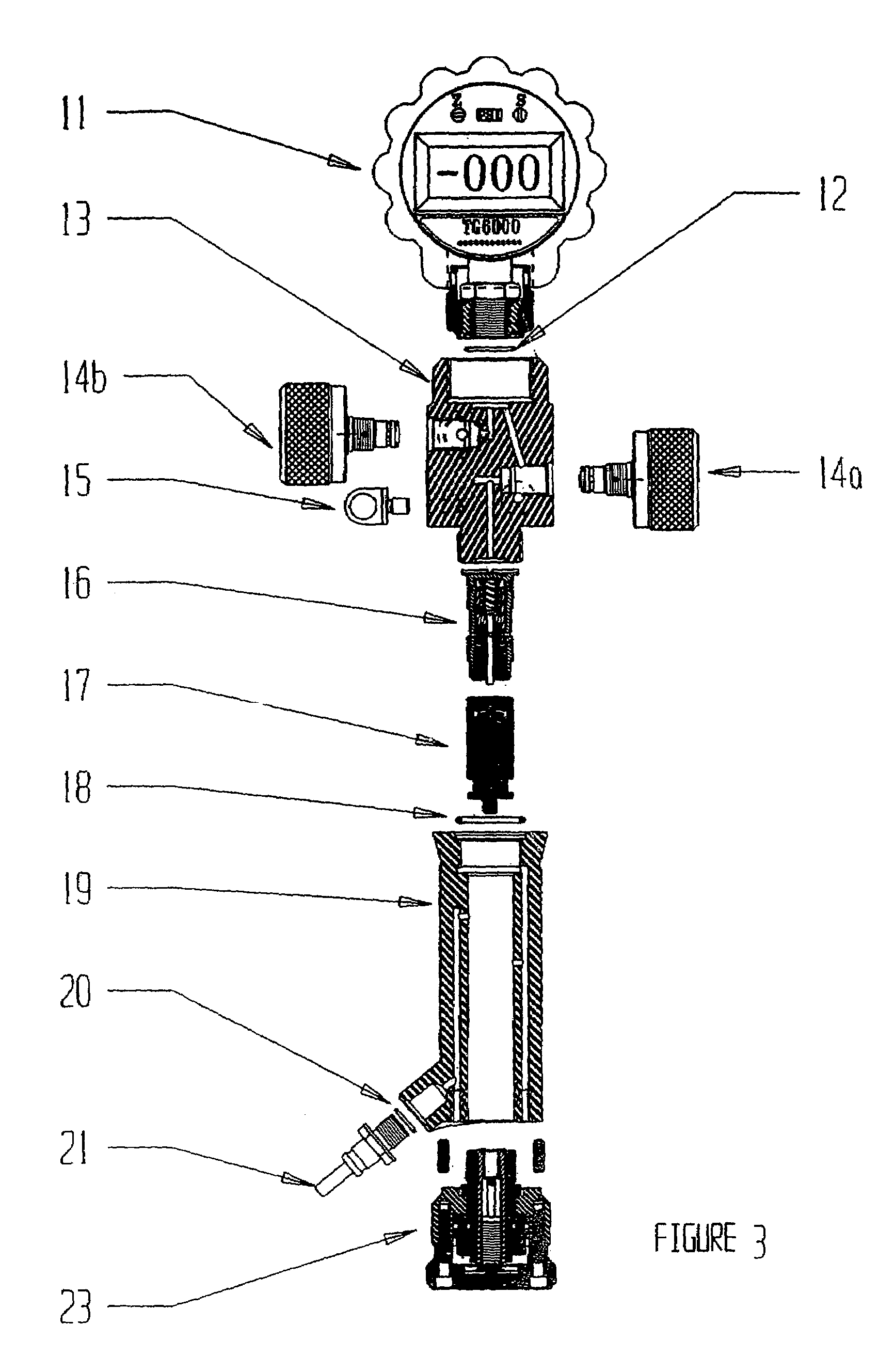

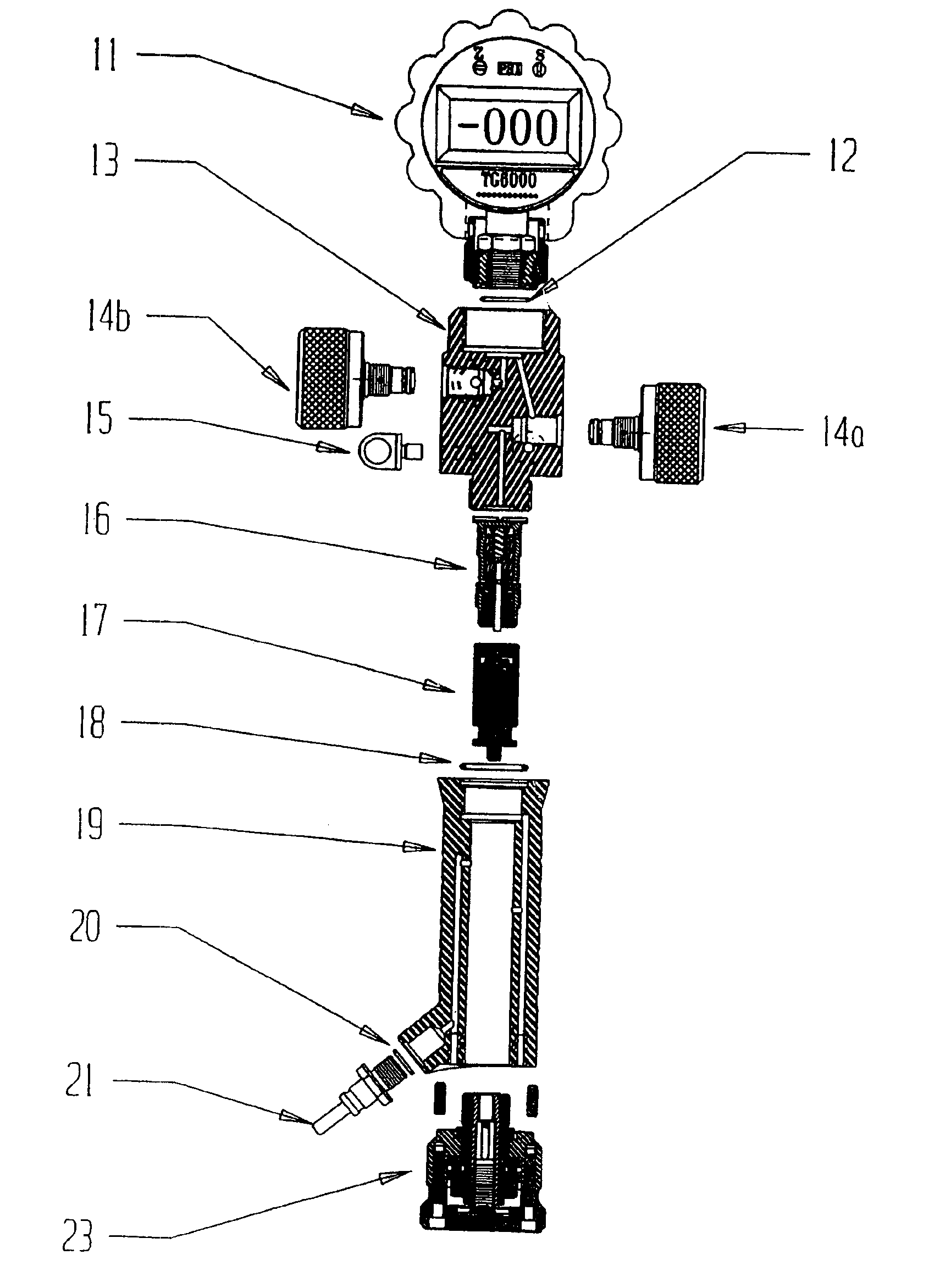

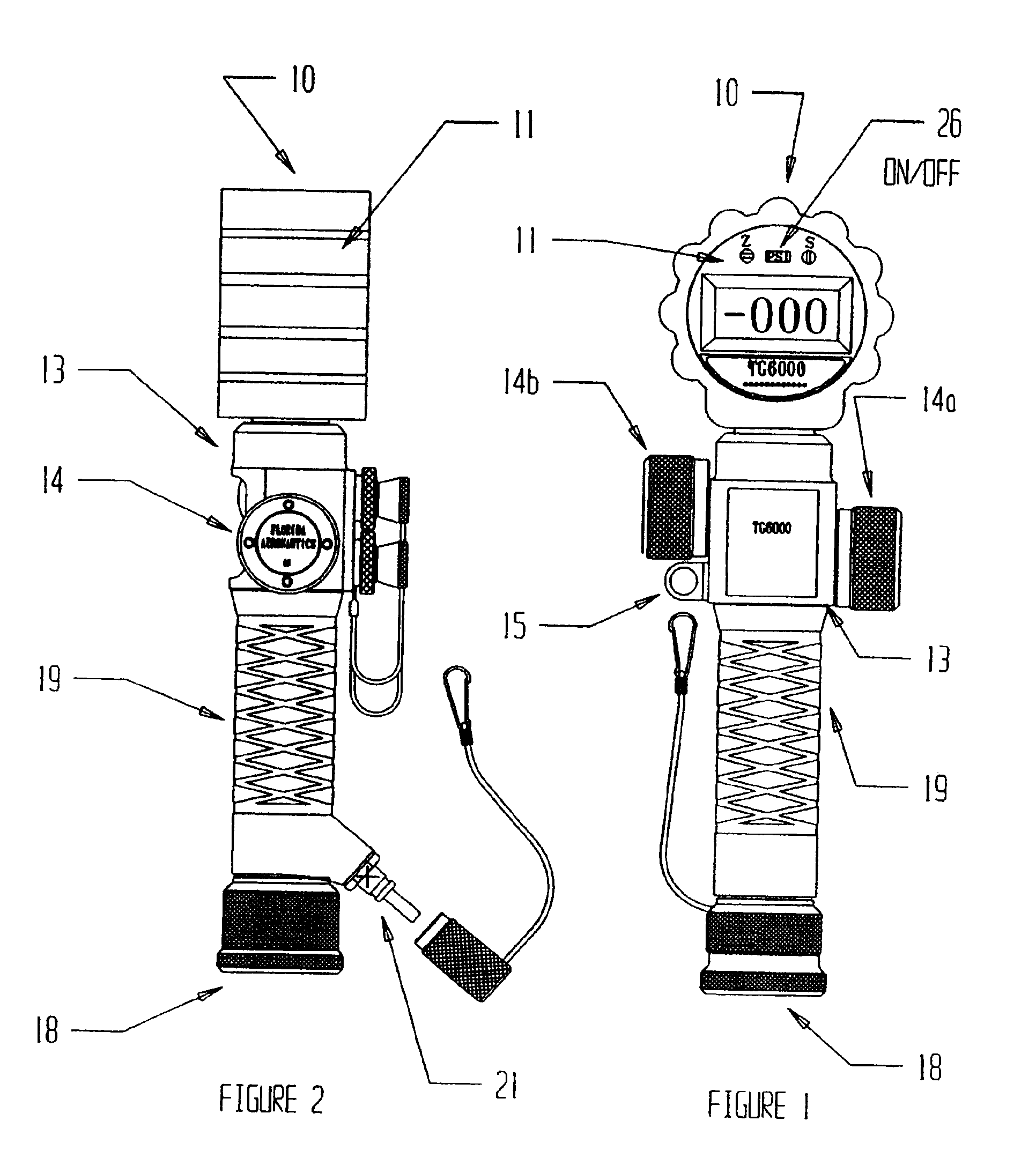

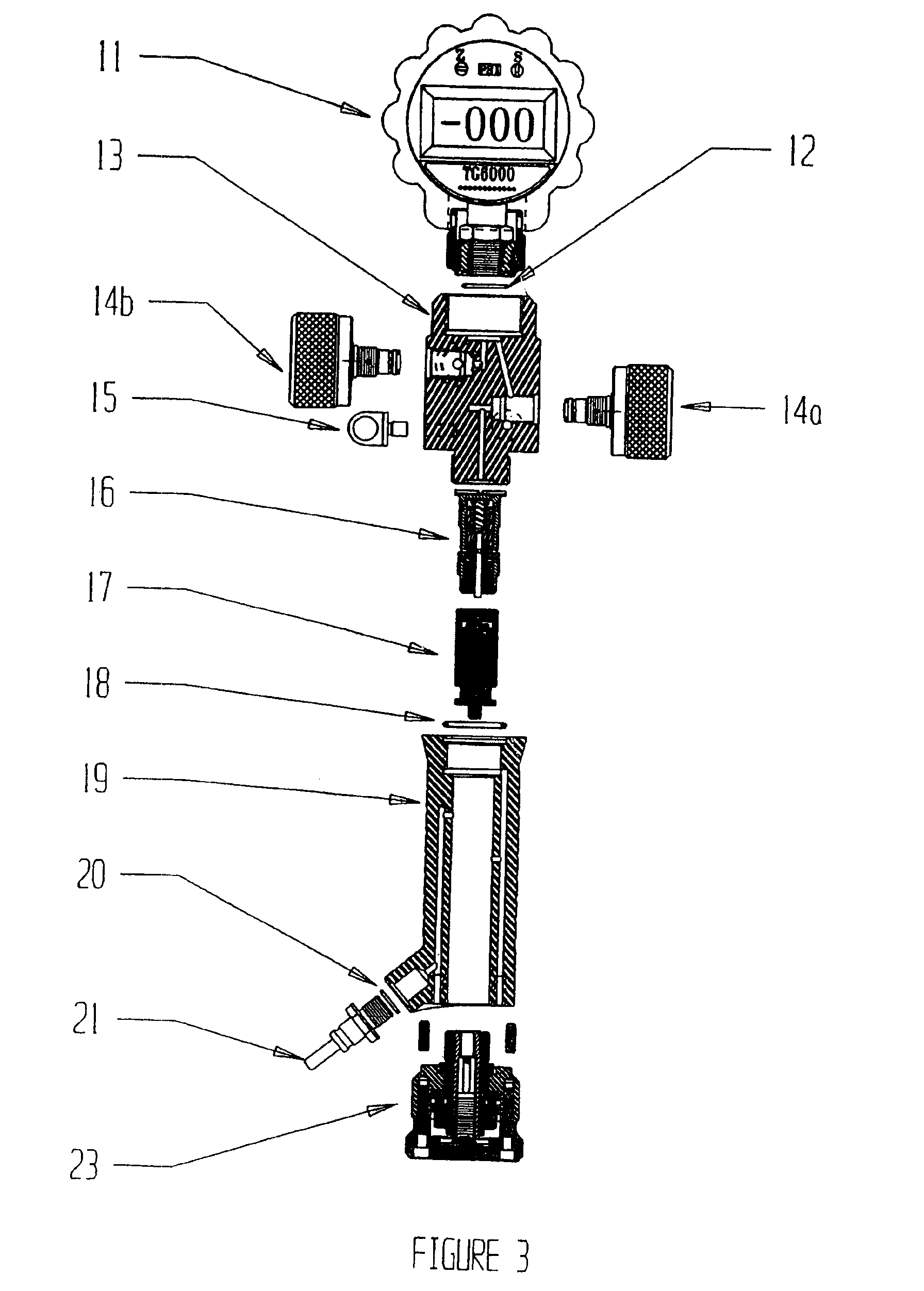

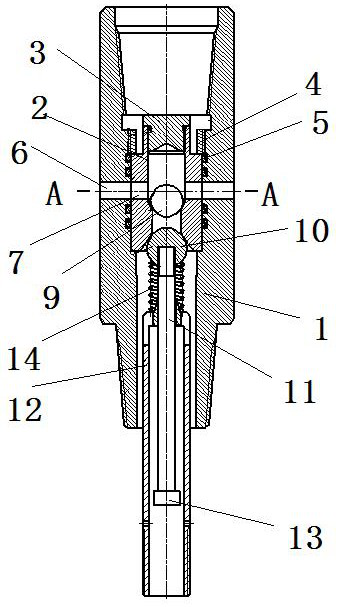

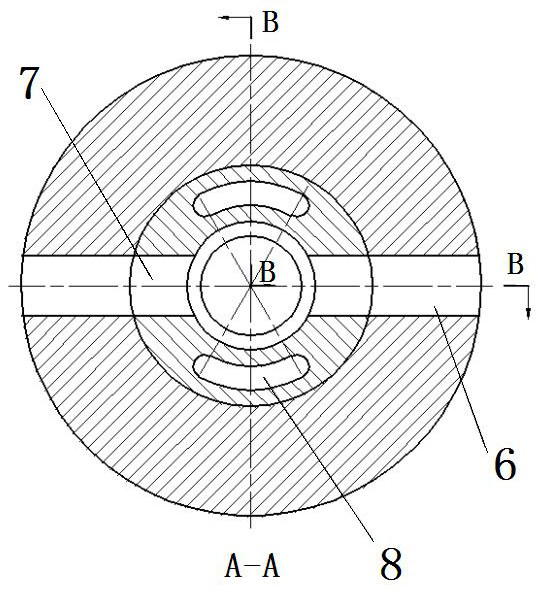

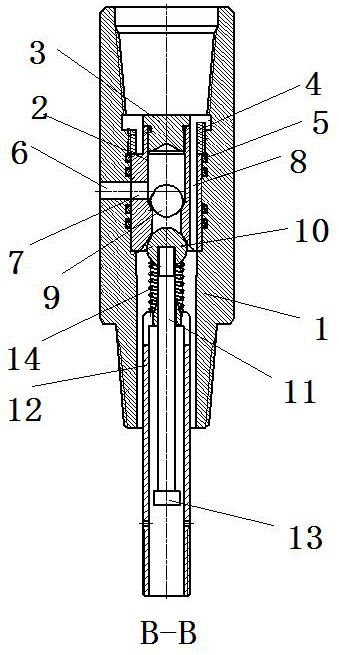

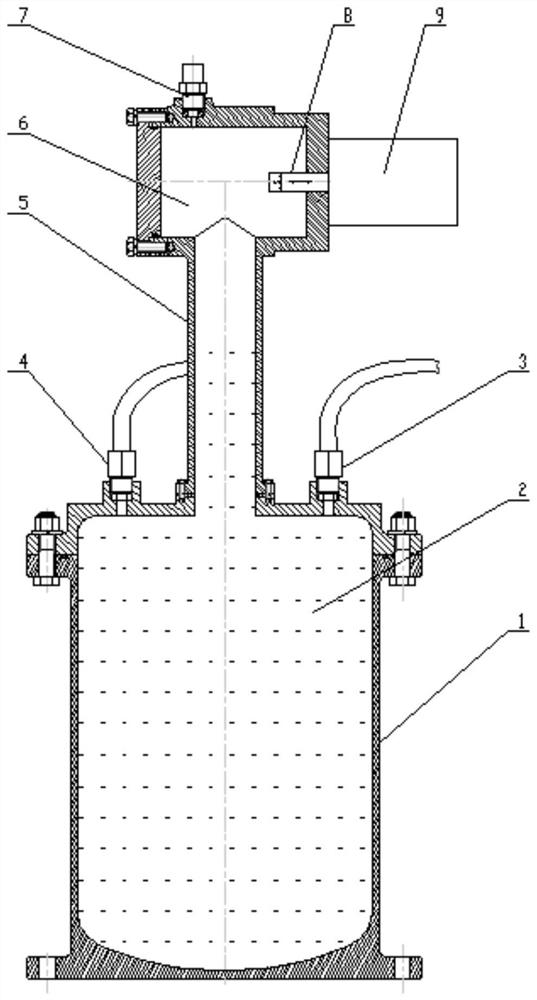

Digital pressurization compound terminal

InactiveUS7096881B1Facilitated releaseAccurate collectionOperating means/releasing devices for valvesServomotor componentsHigh resistanceCoupling

A digital pressurization compound terminal 10 comprising a high accuracy digital pressure gauge 11 sheltered in a silicon housing, main body 13 made of a high-resistance allow and dimensioned to be held in the palm of the user's hand, o-ring 12, control or HP valves 14, ring 15, regulator assembly valve 16, equipped piston 17, second o-ring 18, inferior body and handle 19, third o-ring 20, male quick coupling 21, screw 22, regulator setting wheel 23, purging female quick coupling 24, service female quik coupling 25 and on-off switch 26.

Owner:FERNANDEZ MANUEL ROLAND

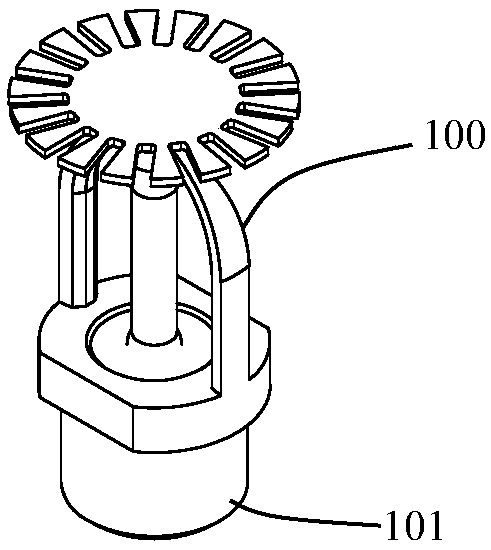

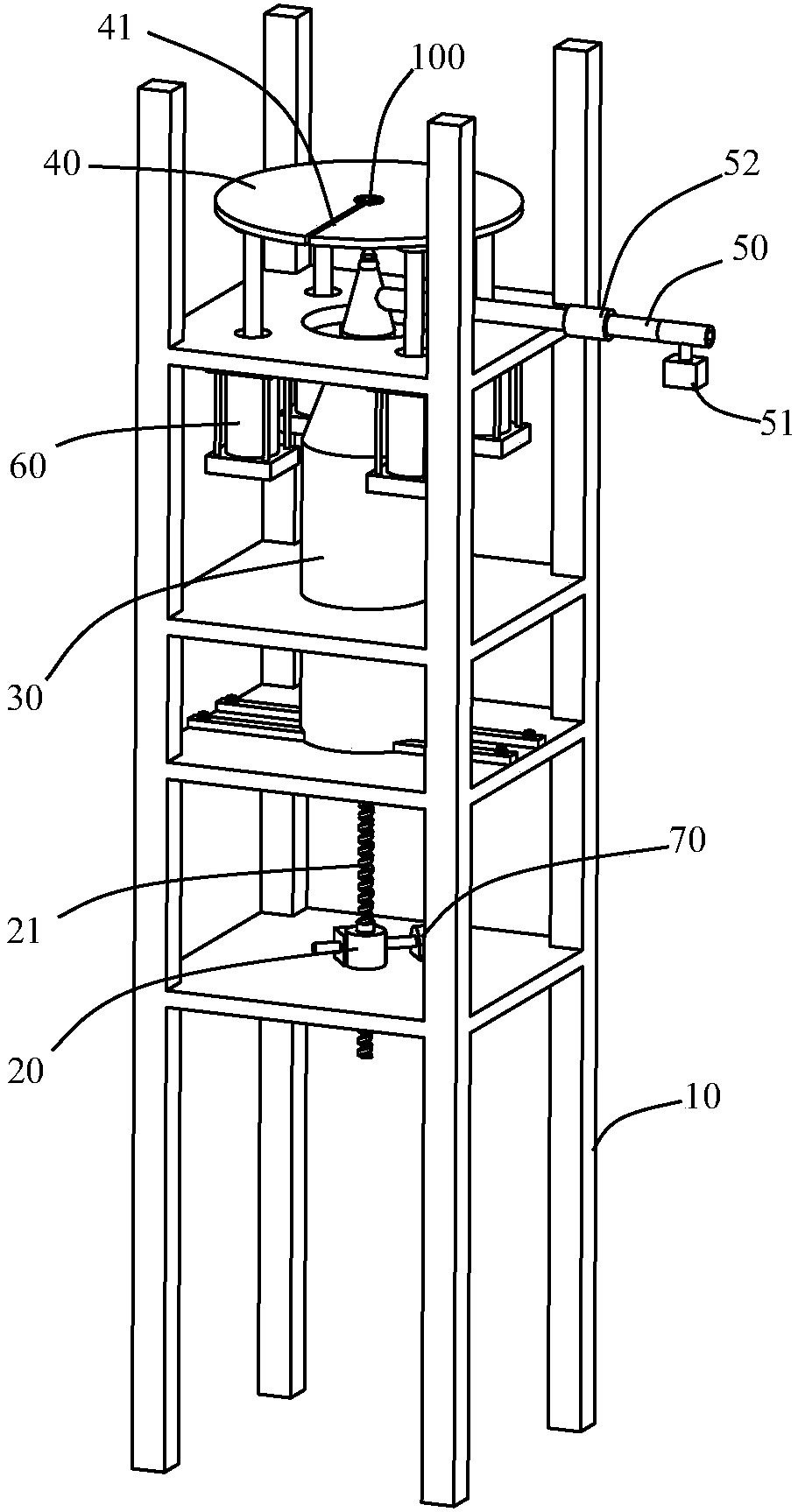

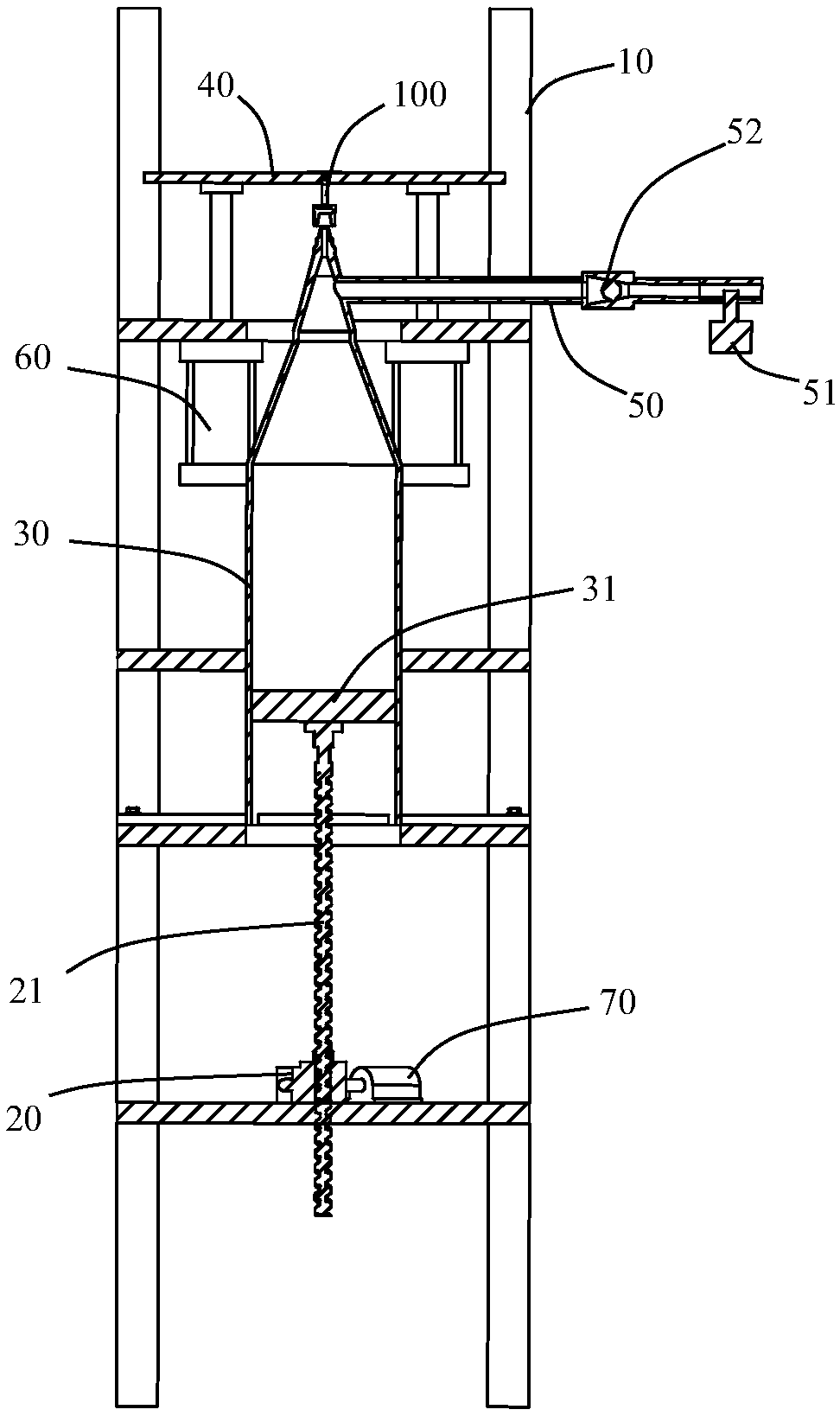

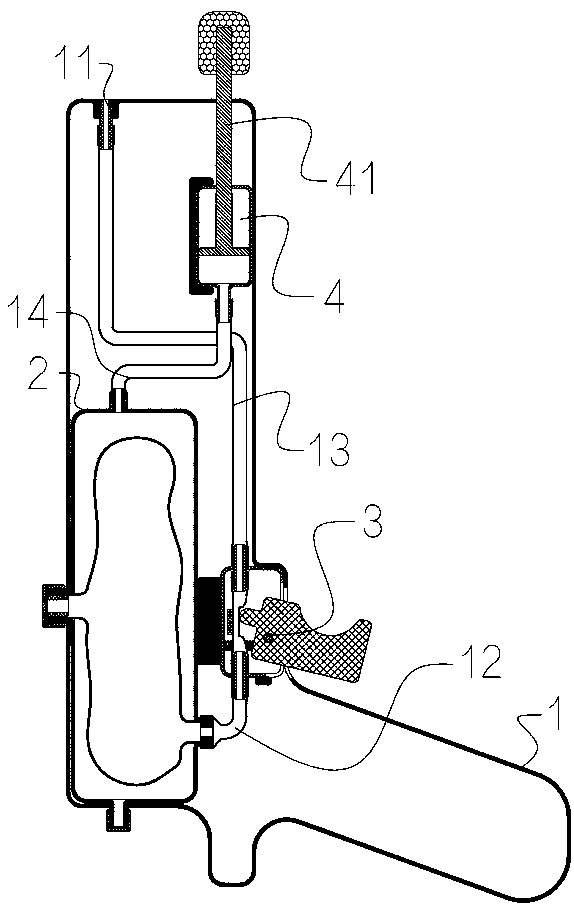

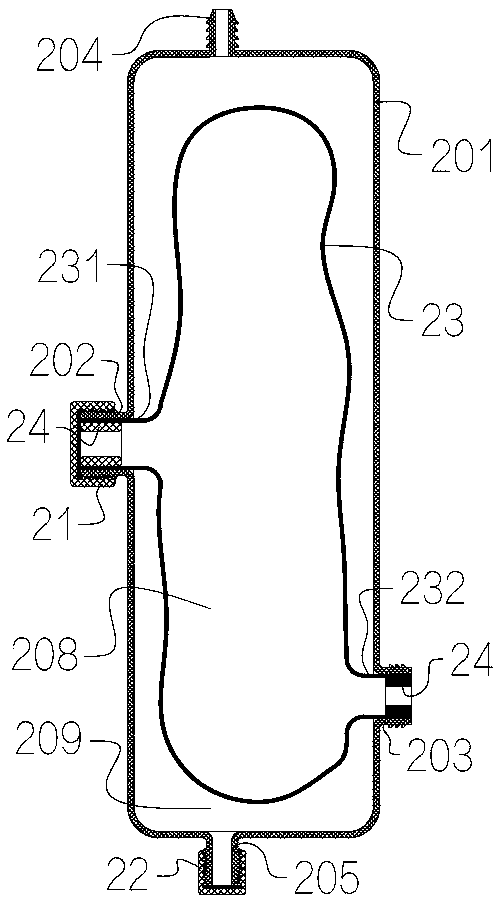

Sealing performance detection device for fire-fighting spray head

InactiveCN107643151AReduce water consumptionFast pressurizationMeasurement of fluid loss/gain rateEngineeringCylinder block

The invention discloses a sealing performance detection device for a fire-fighting spray head. The sealing performance detection device comprises a support, a screw rod elevator, a piston cylinder, aspraying head positioning plate and air cylinders, wherein the piston cylinder is fixed in the support, a piston is arranged in the piston cylinder, the top of the piston cylinder is provided with a water outlet port which can be in butt joint with a joint of a fire-fighting spray head to be detected, and a water inlet pipe used for injecting water into the piston cylinder is further arranged on the piston cylinder; the screw rod elevator is fixed in the support, and the top end of the lifting screw rod of the screw rod elevator is fixedly connected with the piston; and the fire-fighting sprayhead to be detected is fixed in the spray head positioning plate, a plurality of cylinder bodies of the air cylinders are fixed on the support, and the spray head positioning plate is fixedly connected with push rods of the air cylinders. The sealing performance detection device is small in water consumption, the pressure is adjustable in the detection process, the pressurization speed is high, the detection speed is high, and the efficiency is high.

Owner:DONGHUA UNIV

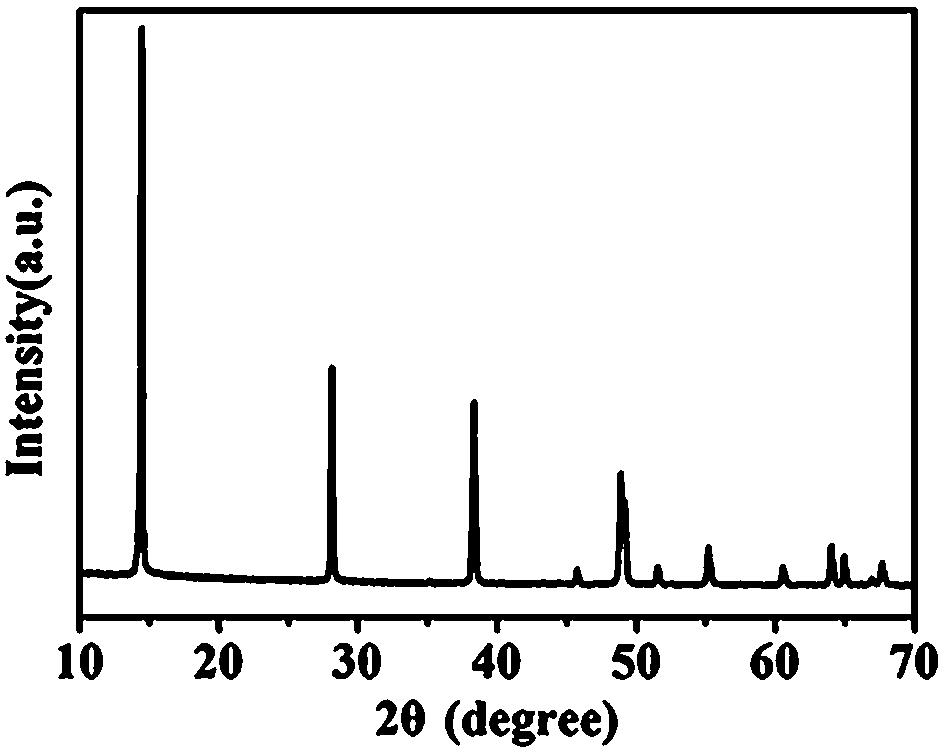

Production technology for preparing boehmite microcrystalline powder

InactiveCN108275706AFast pressurizationEasy to manage pressureAluminium oxides/hydroxidesFiltrationWater vapor

The invention discloses a production technology for preparing boehmite microcrystalline powder, and belongs to the field of ceramic materials. A high-pressure hydrothermal kettle is used, and cheap industrial alumina trihydrate with thick raw crystal (D50 is about 13 microns) is used as a raw material, and the boehmite microcrystalline powder is prepared through heating and pressurization with water vapor. The production technology comprises the following specific steps: firstly, slurrying the industrial alumina trihydrate powder with distilled water, and pouring into the high-pressure hydrothermal kettle with a stirring function, wherein the stirrer is always in a working state during a reaction; then, introducing the water vapor for heating and pressurization, preserving the pressure after a certain pressure is reached to obtain boehmite slurry; finally, naturally performing air cooling on the obtained slurry to room temperature, and then repeatedly performing suction filtration withdistilled water for washing till filtrate is neutral, and drying to obtain the boehmite microcrystalline powder which has small particle size (D50 is 2.97 microns) and diamond-shaped and uniformly distributed particles.

Owner:QILU UNIV OF TECH

Digital pressurization compound terminal

InactiveUS6935359B2Facilitated releaseAccurate collectionOperating means/releasing devices for valvesServomotor componentsHigh resistanceCoupling

A digital pressurization compound terminal 10 comprising a high accuracy digital pressure gauge 11 sheltered in a silicon housing, main body 13 made of a high-resistance allow and dimensioned to be held in the palm of the user's hand, o-ring 12, control or HP valves 14, ring 15, regulator assembly valve 16, equipped piston 17, second o-ring 18, inferior body and handle 19, third o-ring 20, male quick coupling 21, screw 22, regulator setting wheel 23, purging female quick coupling 24, service female quik coupling 25 and on-off switch 26.

Owner:FERNANDEZ MANUEL ROLAND

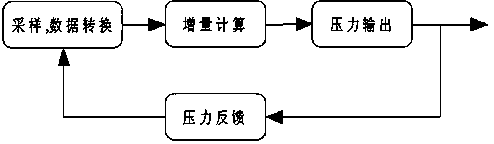

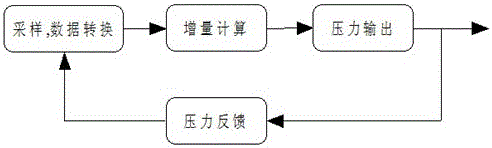

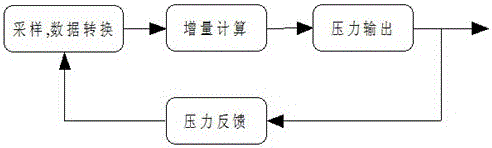

Pneumatic servo system for grinder

ActiveCN104354093AFast pressurizationHigh pressurization accuracyLapping machinesPull forceEngineering

The invention discloses a pneumatic servo system for a grinder. The system comprises a controller, a sampling module and an air cylinder, wherein the sampling module comprises a pressure sensor, a pulling force sensor and an in-position sensor; the air cylinder comprises an upper air cylinder and a lower air cylinder; the pressure sensor is used for detecting the pressure of an upper grinding disk to workpieces; the pulling force sensor is used for detecting the pulling force of the cylinder to the upper grinding disk; the in-position sensor is used for detecting the in-position information of the upper grinding disk; according to a pressure signal detected by the pressure sensor and a pulling force signal detected by the pulling force sensor, the controller outputs a control signal to control the air pressure of the upper cylinder and the air pressure of the lower cylinder and the pulling force of the upper grinding disk, so as to control the upper grinding disk to rise or fall, and the pressure of the upper grinding disk to the workpieces is controlled according to a preset working procedure. Through the adoption of the system, the upper grinding disk is raised and fallen smoothly, the pressurization is stable, the precision is high, the rate of finished products of the workpieces is effectively increased, and the damage ratio of the workpieces is decreased.

Owner:盈利时表业(东莞)有限公司

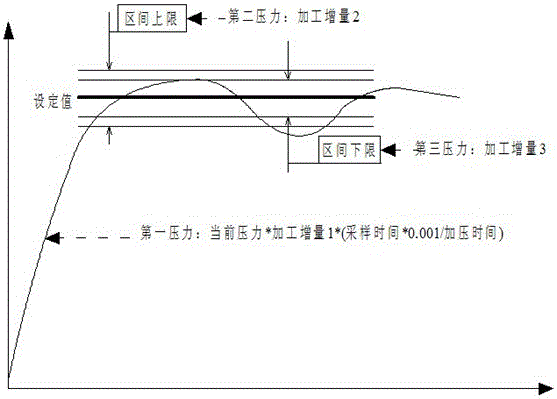

Three-stage pressure control method for plane grinding machine

InactiveCN105014538AReduce unbalanced stressFast pressurizationAutomatic grinding controlLower limitThree stage

The invention discloses a three-stage pressure control method for a plane grinding machine. The three-stage pressure control method includes the pressurization process and the depressurization process. A target pressure value, a pressure upper limit value, a pressure lower limit value, a first stepping pressure value, a second stepping pressure value and a third stepping pressure value are preset, the three-stage pressurization and depressurization mode is adopted, and pressurization is conducted through large stepping pressure at the beginning so that the pressure can rapidly reach the pressure upper limit value; pressurization is then conducted through the slightly smaller stepping pressure, the speed is decreased, and the pressure reaches the pressure lower limit value; and finally, pressurization is conducted through the smallest stepping pressure, and the pressure slowly reaches the set value of the pressure at a constant speed. The depressurization process is the inverse process of the pressurization process. By means of the pressurization and depressurization mode, the pressurization speed can be high; meanwhile, the pressurization accuracy is high, uniformity is high, the unbalanced pressure on workpieces is reduced, and the yield is increased; and the three-stage pressurization process is further divided into the pressurization achieved through the small stepping pressure and the slow pressurization, and therefore the excessively-large pressure and low accuracy are avoided.

Owner:SUZHOU DERUILANG INTELLIGENT TECH

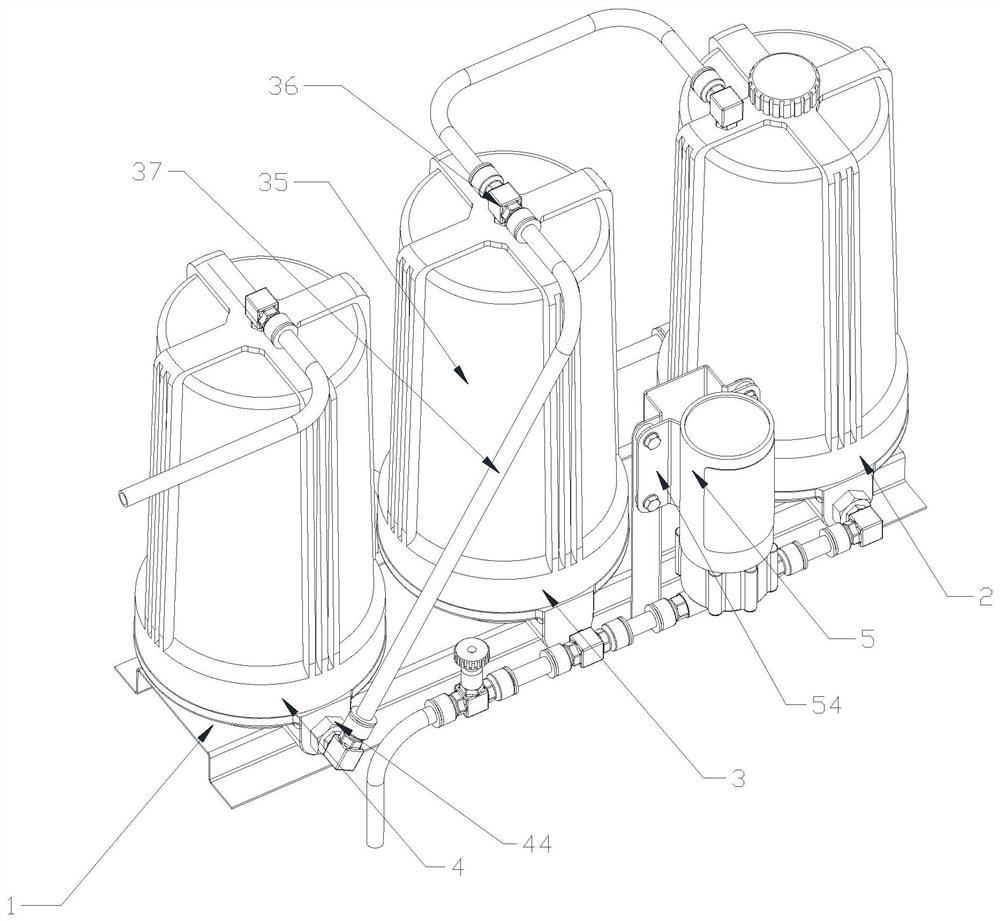

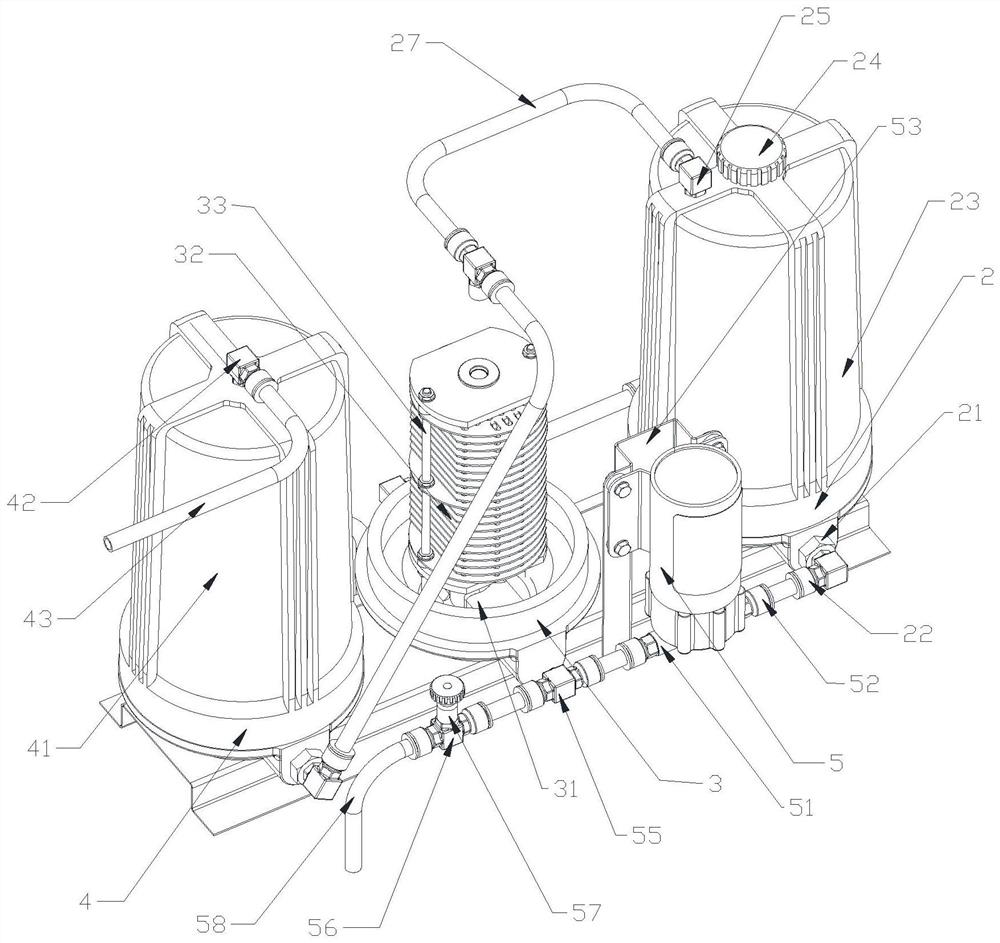

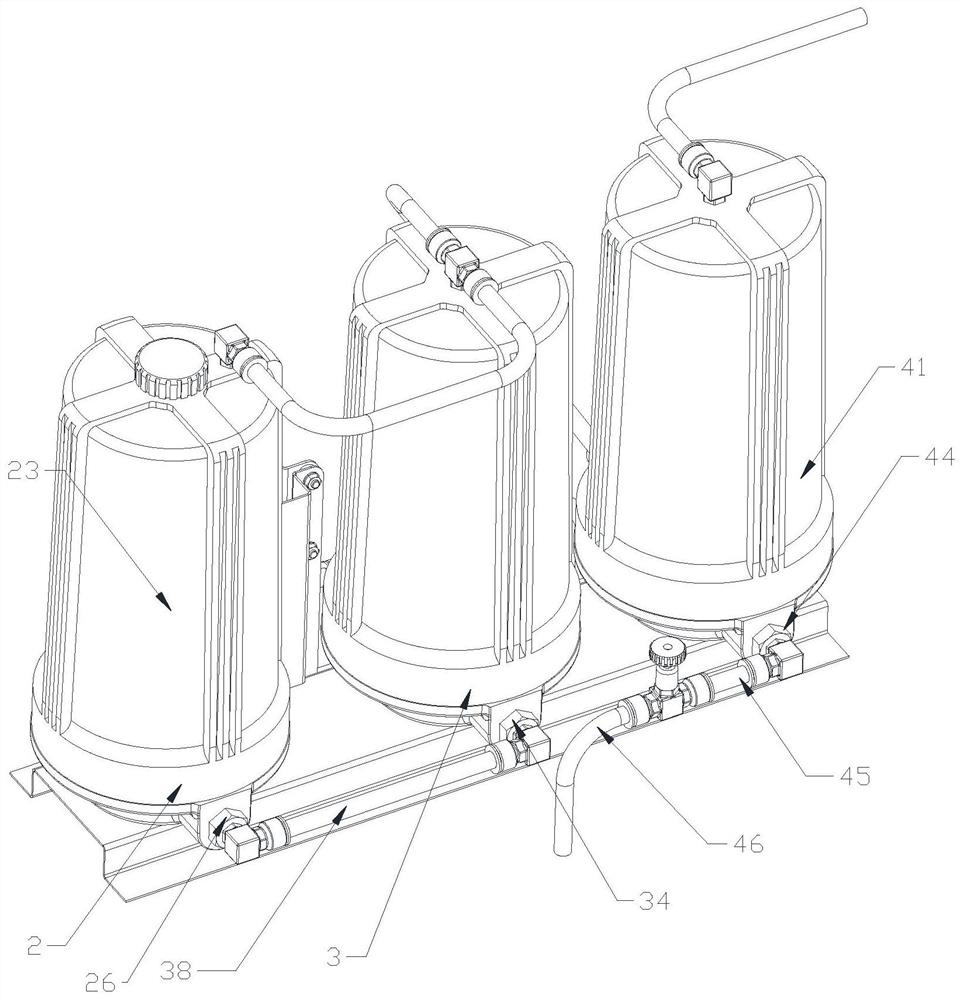

Automatic gastrointestinal decompression device

PendingCN112023128AFast pressurizationReduce patient burdenMedical devicesIntravenous devicesGastric pressureMedical staff

The invention discloses an automatic gastrointestinal decompression device. The device comprises a device base, wherein a liquid treatment tank base, a gas treatment tank base and a buffer tank base are arranged on the device base; a negative pressure pumping rack is arranged on one side of the device base; a negative pressure pumping machine is arranged on the negative pressure pumping rack; a first connector is arranged on one side of the liquid treatment tank base; a liquid treatment tank is arranged on the liquid treatment tank base; a liquid outlet connector is arranged on one side of thenegative pressure pumping machine; a pumping connector is arranged on the other side of the negative pressure pumping machine; a first pipeline is arranged between the liquid outlet connector and thefirst connector; at least one extension pipe is arranged on one side of the pumping connector according to the length; a valve section is arranged at one end of each extension pipe; a flow valve is arranged on each valve section; an insertion pipe is arranged at one end of each valve section; a gas treatment tank is arranged on the gas treatment tank base; and a buffer tank is arranged on the buffer tank base. Accordingly, medical staff can adjust different demand conditions of patients conveniently, when the gastric pressure of the patients is too large, the pressurization speed can be increased, and the burden of the patients is relieved.

Owner:南京市江宁医院

A pressure control method of a grinding machine pneumatic servo system

ActiveCN104369087BReduce unbalanced stressFast pressurizationSemiconductor/solid-state device manufacturingLapping machinesLower limitAtmospheric pressure

The invention discloses a pressure control method of a grinder air pressure servo system. A three-section pressurization and pressure reduction mode is adopted, so that pressurization is performed with larger steeping pressure to rapidly reach a pressure upper limit value at the beginning, then the pressurization is performed with smaller steeping pressure to reduce speed and reach a pressure lower limit value, and finally the pressurization is performed with the smallest steeping pressure to enable the speed to be constant slowly and reach a pressure set value. By means of the pressurization mode, the pressurization speed can be high, meanwhile the pressurization accuracy is high, uniformity is good, unbalance pressure of a workpiece is reduced, and the finished product rate is improved.

Owner:珠海宾赫机械设备有限公司

Water gun fixedly provided with water storage tank

InactiveCN109341413ASmall volumeContinuous shooting is effectiveLiquid ejecting gunsWater storage tankSpray nozzle

The invention relates to the technical field of liquid spray guns, and discloses a water gun fixedly provided with a water storage tank. The water gun comprises a water gun shell, the water storage tank, a nozzle, a control water valve and an air charging device. The control water valve comprises a trigger, a flexible water bag is arranged in the water storage tank, and the water storage tank is provided with a water inlet, a water outlet, an air inlet and an air outlet. The water inlet and the air outlet of the water storage tank are exposed to the water gun shell, the water bag is provided with a water inlet bag mouth and a water outlet bag mouth, and the water inlet bag mouth communicates with the water inlet in a sealed manner. The water outlet bag mouth communicates with the water outlet in a sealed manner, the water inlet is covered with a water opening cover, and the air outlet is covered with an air opening cover. The water outlet communicates with the control water valve in asealed manner, the control water valve communicates with the nozzle in a sealed manner, and the air inlet communicates with the air charging device in a sealed manner. The shooting angle of the watergun is not limited, water in the water bag is nearly all sprayed out, and the water adding frequency of a player can be reduced during one game.

Owner:GUANGZHOU YUXUAN INFORMATION TECH CO LTD

Underground pressure release valve and hydraulic shaping pipe column

ActiveCN112576221AImprove shaping efficiencyConvenient multi-levelWell/borehole valve arrangementsSealing/packingPressure riseStructural engineering

The invention discloses an underground pressure release valve and a hydraulic shaping pipe column. The underground pressure release valve comprises an outer sleeve, a valve seat, a valve element and apiston connecting piece, wherein a liquid outlet hole is formed in the outer sleeve, the valve seat is fixed in the outer sleeve and is in sealing fit with the outer sleeve, a pressurizing channel and a pressure release channel are formed in the valve seat, the piston connecting piece can move downwards along with a piston of a hydraulic booster when pressurizing the interior of the outer sleeve,a transmission relation is established between the piston connecting piece and the valve element when the piston connecting piece moves downwards by a certain distance, and the valve element is disengaged from the valve seat to communicate the pressure relief channel. According to the underground pressure release valve, when the piston connecting piece descends to a certain position, the valve element can be automatically driven to be disengaged from the valve seat, the pressure release channel is connected, then the hydraulic shaping column automatically releases pressure, the whole pressurerelease process is conducted underground, frequent pressure rising and releasing on the ground manually are not needed, the pressure release speed is high, the process is safe and reliable, manpowerand material resources can be saved, and pipe column shaping efficiency can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

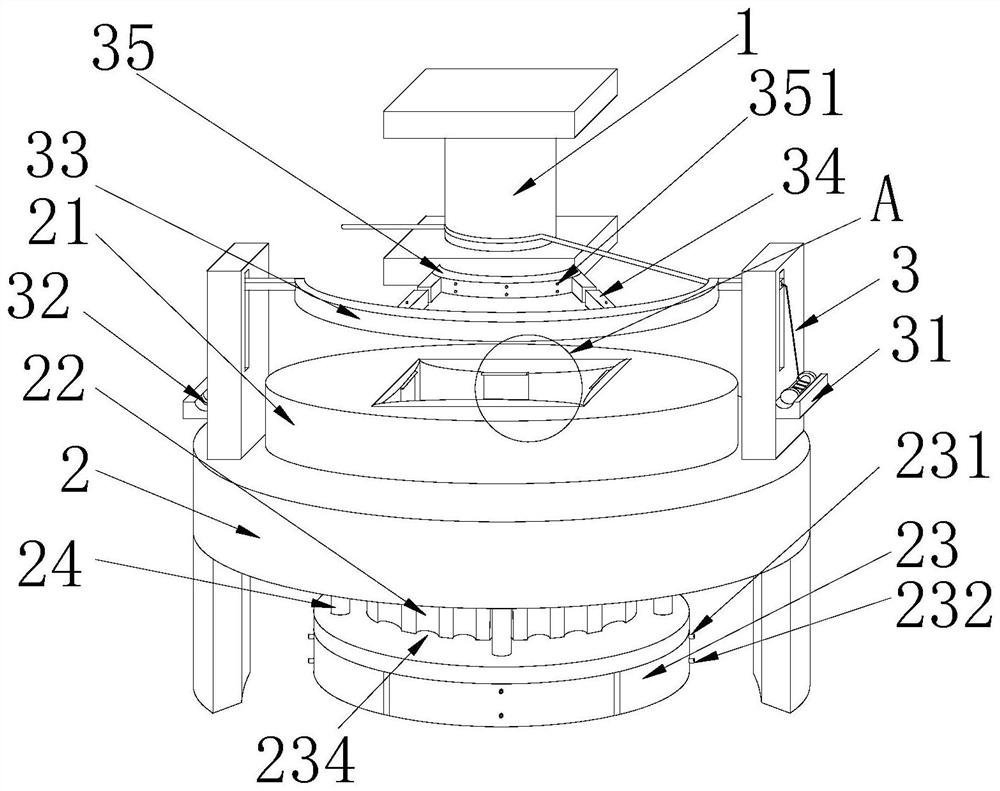

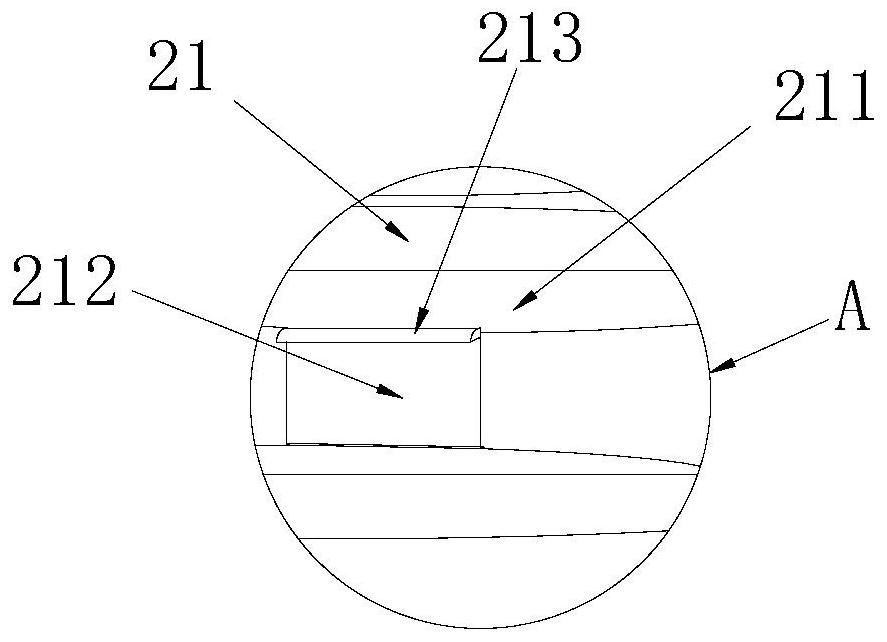

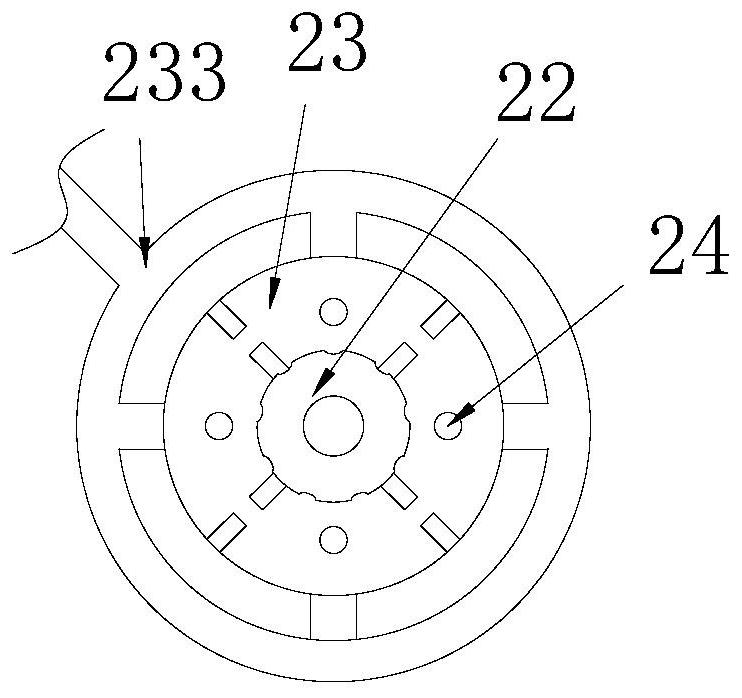

Servo control system device applied to wet-type magnetic material molding

The invention relates to the field of wet-type magnetic material molding, in particular to a servo control system device applied to wet-type magnetic material molding. The servo control system device applied to wet-type magnetic material molding is simple and ingenious in design, time and labor are saved, system valve pipes are simple in structure, operation is safe and reliable, switching operation between the high speed and the low speed can be achieved, and the requirements of a high-requirement product production standard can be met.

Owner:南通市腾达锻压机床厂

A grinder pneumatic servo system

The invention discloses a pneumatic servo system for a grinder. The system comprises a controller, a sampling module and an air cylinder, wherein the sampling module comprises a pressure sensor, a pulling force sensor and an in-position sensor; the air cylinder comprises an upper air cylinder and a lower air cylinder; the pressure sensor is used for detecting the pressure of an upper grinding disk to workpieces; the pulling force sensor is used for detecting the pulling force of the cylinder to the upper grinding disk; the in-position sensor is used for detecting the in-position information of the upper grinding disk; according to a pressure signal detected by the pressure sensor and a pulling force signal detected by the pulling force sensor, the controller outputs a control signal to control the air pressure of the upper cylinder and the air pressure of the lower cylinder and the pulling force of the upper grinding disk, so as to control the upper grinding disk to rise or fall, and the pressure of the upper grinding disk to the workpieces is controlled according to a preset working procedure. Through the adoption of the system, the upper grinding disk is raised and fallen smoothly, the pressurization is stable, the precision is high, the rate of finished products of the workpieces is effectively increased, and the damage ratio of the workpieces is decreased.

Owner:盈利时表业(东莞)有限公司

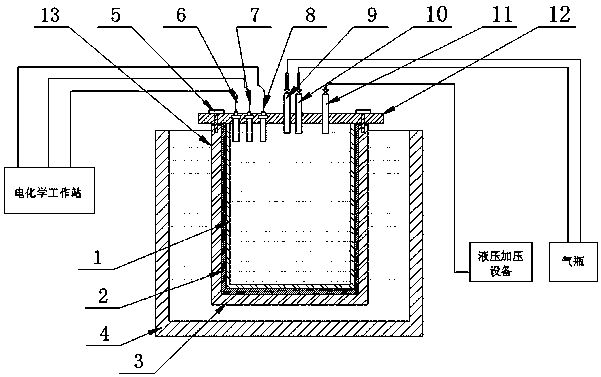

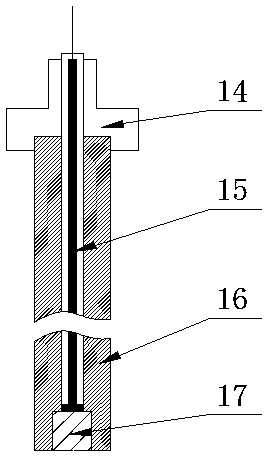

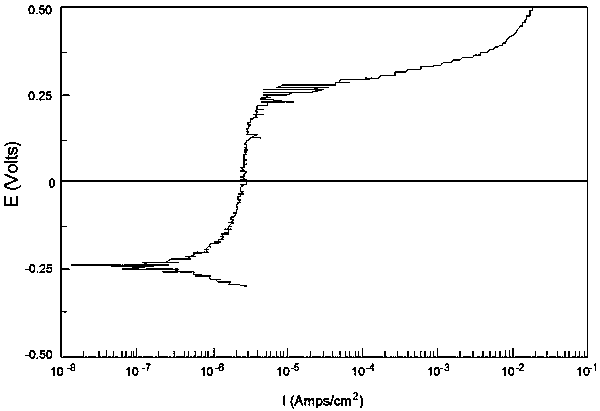

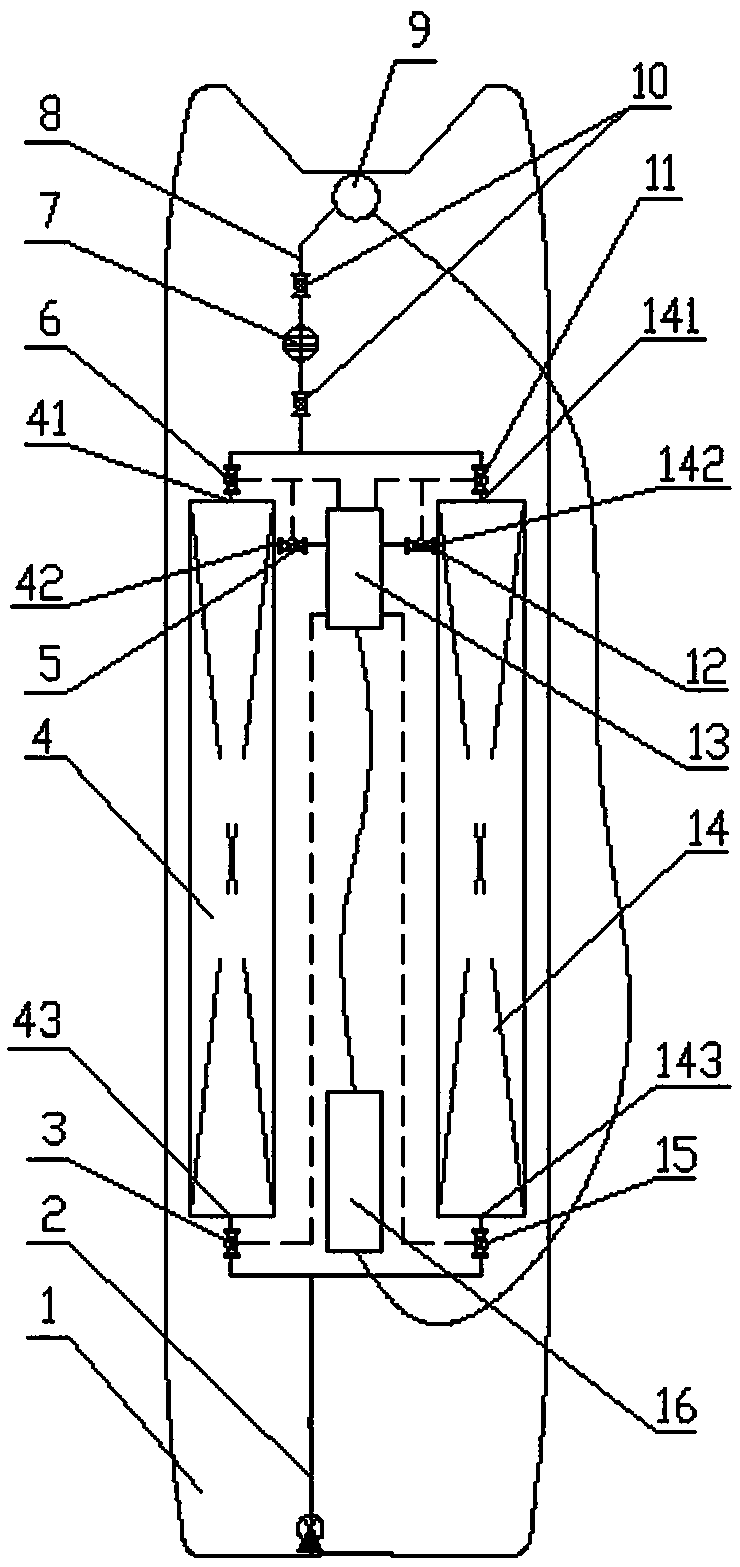

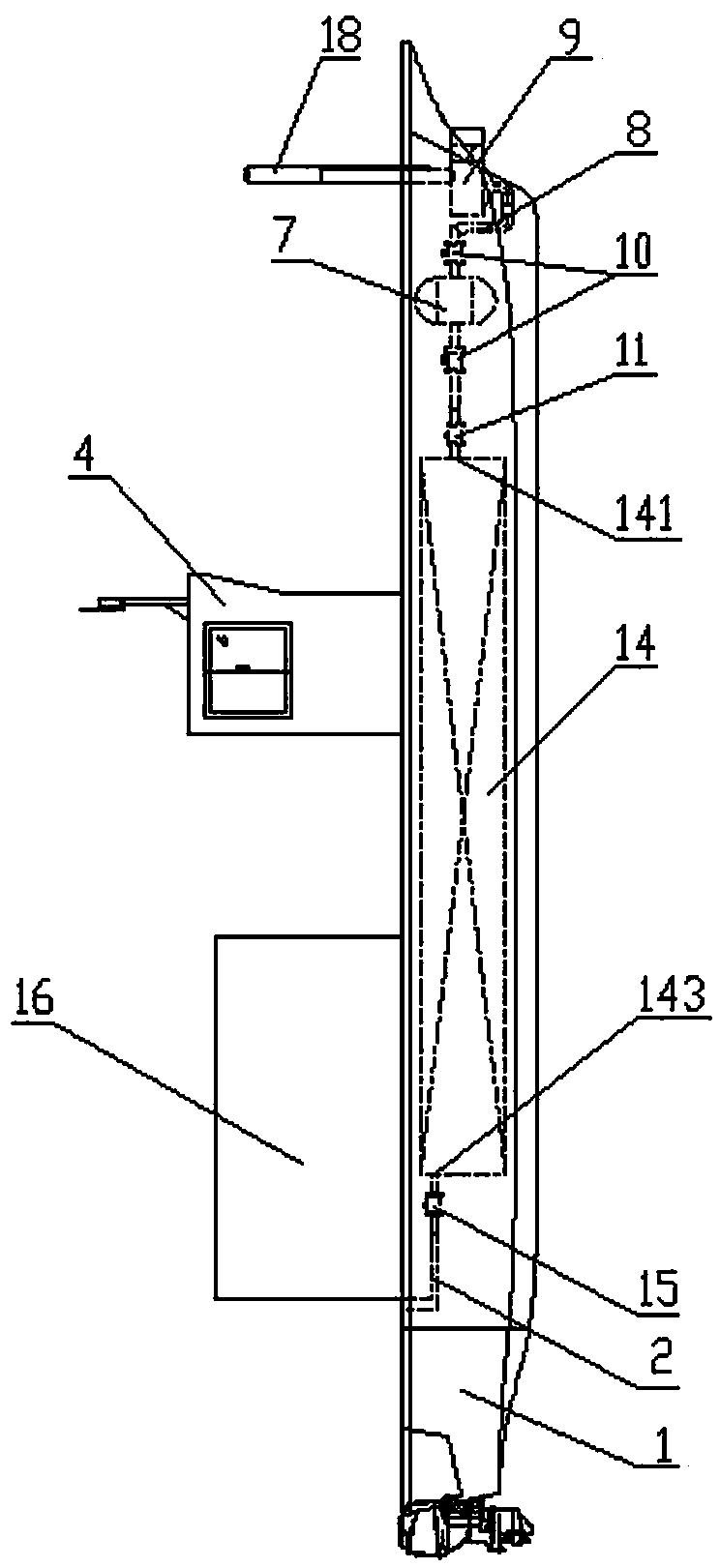

An electrolytic cell device for simulating deep-sea environment electrochemical tests

ActiveCN106644917BReflects corrosion electrochemical performanceEasy to operateWeather/light/corrosion resistanceTemperature controlElectrolysis

The invention provides an electrolytic bath apparatus used for simulating a deep-sea environment for electrochemical testing, belonging to the field of corrosion testing of metal materials. The electrolytic bath apparatus comprises an electrolytic bath main body which is prepared from at least three layers of different metal materials, i.e., an inner corrosion-resistant layer, an outer pressure-resistant layer and an electromagnetic wave shielding layer arranged between the inner corrosion-resistant layer and the outer pressure-resistant layer; three electrode subassembly installing holes, two air vents and one hydraulic pressurization hole are preset in the top cover of an electrolytic bath; and the hydraulic pressurization hole is connected with hydraulic pressurization equipment via a connection flexible pipe. The apparatus provided by the invention is based on the electrolytic bath main body for electrochemical measurement, can realize simulation of the deep-sea environment at the same time, and has the advantages of simple operation, low time consumption, economic performance, a large pressure control scope, fast pressurization speed, accurate temperature control, firm and durable structure, etc. Testing data acquired by using the electrolytic bath apparatus can truly reflect the corrosion-electrochemical performance of a metal material in a simulated deep-sea environment, and the electrolytic bath apparatus provides a more favorable corrosion measurement means for research on materials used in deep-sea environments.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

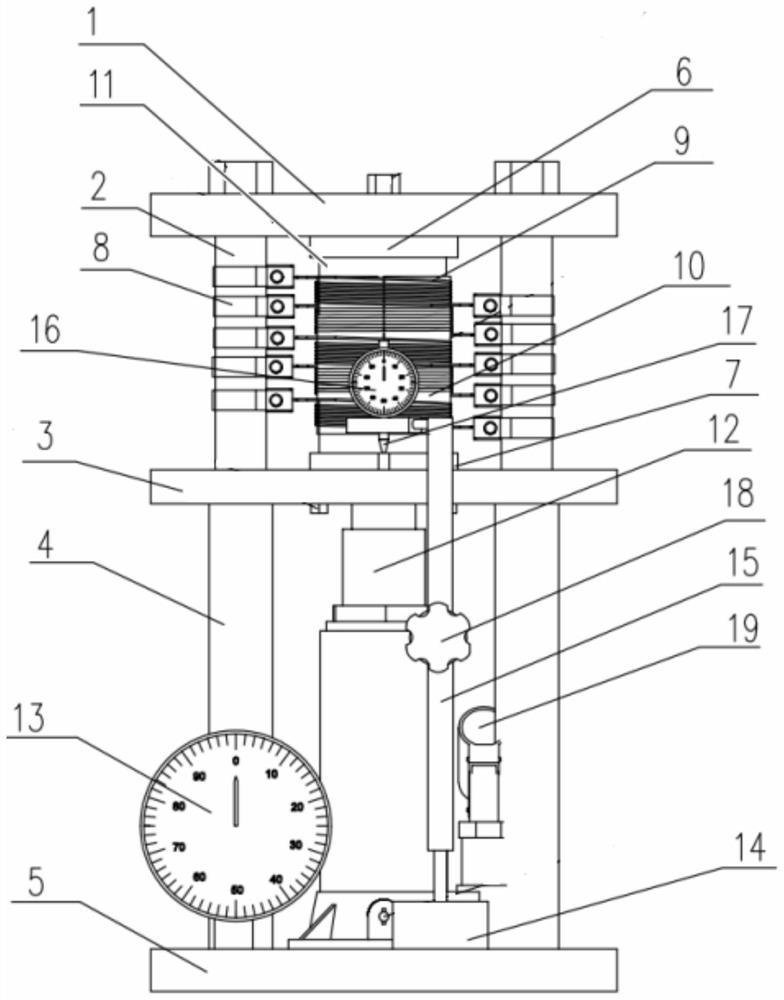

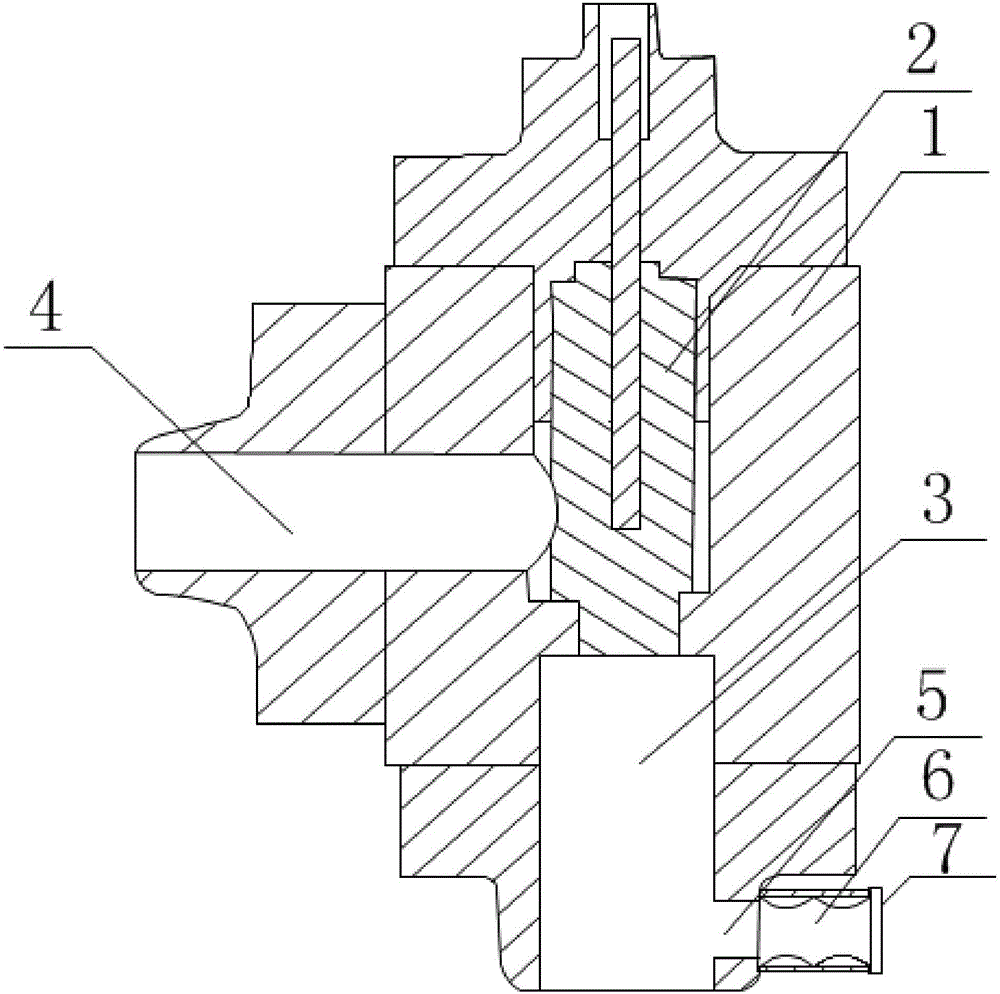

Coke oven heating gas pipeline pressure test device and method

ActiveCN102445313BFast pressurizationReduce labor inputMeasurement of fluid loss/gain rateFixed frameEngineering

The invention discloses a pressure testing device and method for a coke oven heating gas pipeline. The pressure testing device comprises a jack (1), a pressure measuring scale (9), a steel fixing frame (3), an air distribution cylinder (4) and an inflation sleeve (10), and is characterized in that: the jack (1) is a commercially available RCS-series thin hydraulic jack; the pressure indicating measuring scale (9) is a pressure indicating measuring scale which is provided with graduations and is 2.1-2.2 meters in length; the steel fixing frame (3) is formed by welding a carrier rod, an upright post and a bottom plate; the bottom plate is provided with an air inflating hole (7); the air distribution cylinder (4) is an airtight steel air drum; one side of the air distribution cylinder (4) is provided with an air inflating hole, and the other side of the air distribution cylinder (4) is provided with a plurality of air outlet holes; the air inflating hole and the air outlet holes are provided with ball valve switches respectively; and the inflation sleeve (10) is an ordinary bicycle inflation sleeve for supplying air to the air distribution cylinder (4). The pressure testing device for the coke oven heating gas pipeline disclosed by the invention has the advantages of increase in the pressurizing speed and saving in labor force investment due to the application of the hydraulic jack.

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

A Servo Control System Device for Wet Magnetic Material Forming

The invention relates to the field of wet-type magnetic material molding, in particular to a servo control system device applied to wet-type magnetic material molding. The servo control system device applied to wet-type magnetic material molding is simple and ingenious in design, time and labor are saved, system valve pipes are simple in structure, operation is safe and reliable, switching operation between the high speed and the low speed can be achieved, and the requirements of a high-requirement product production standard can be met.

Owner:南通市腾达锻压机床厂

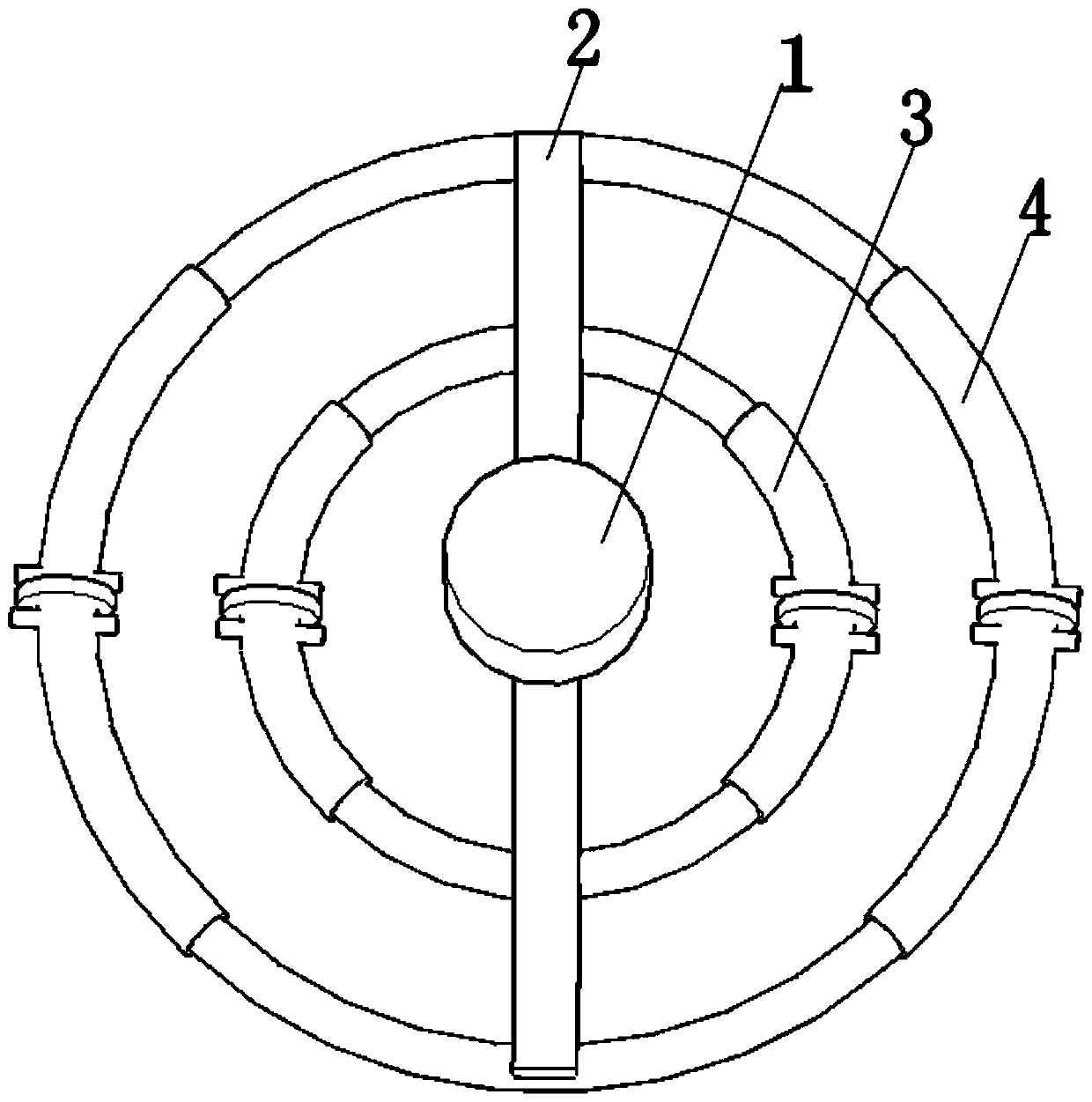

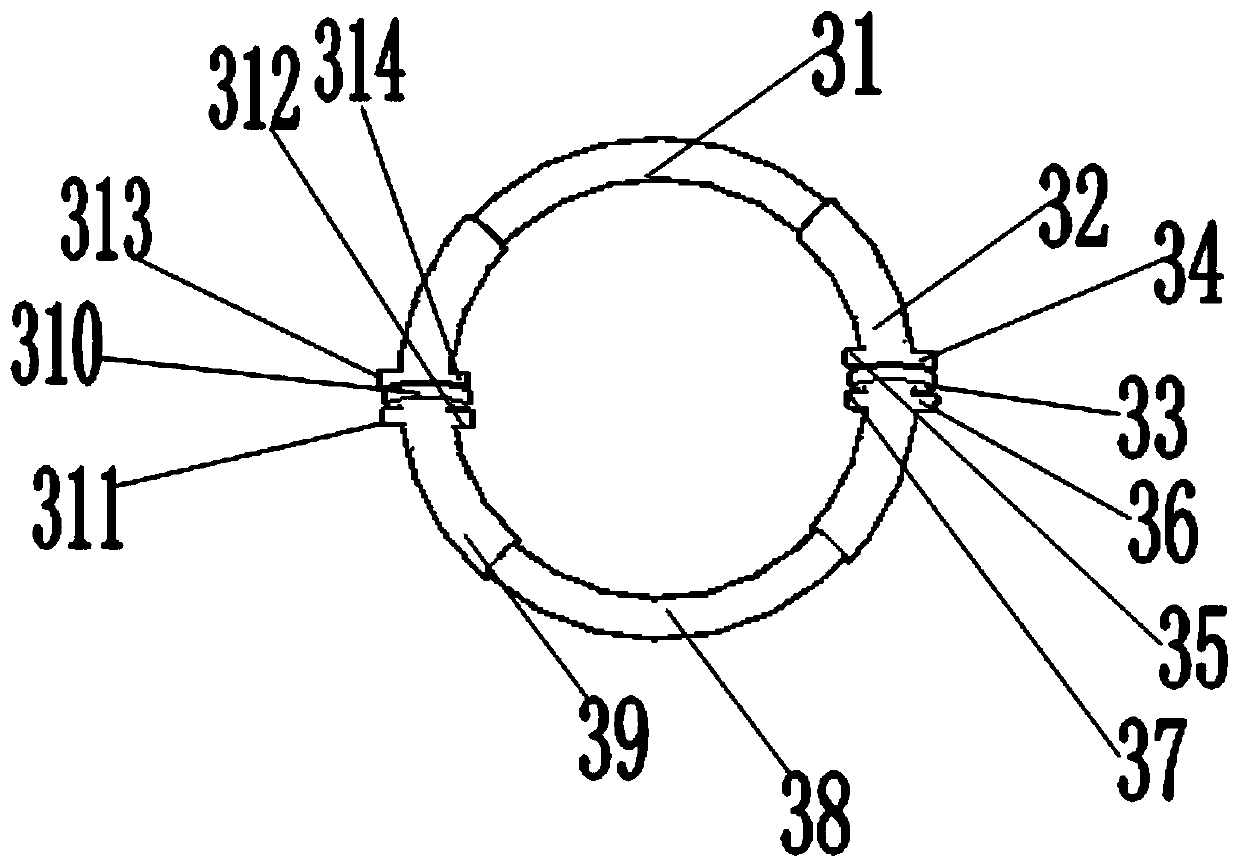

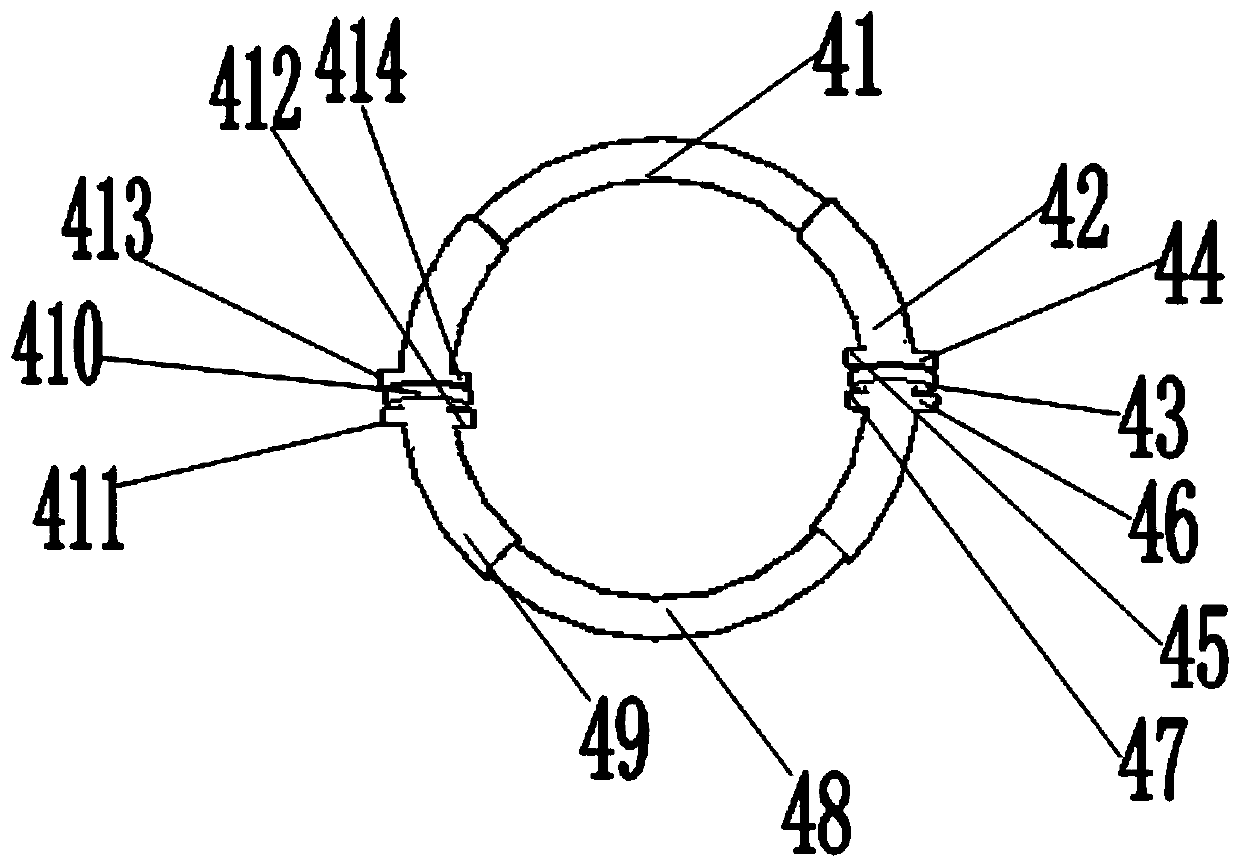

Flat annular mini air pump

InactiveCN110905761AEasy to useEasy to storePositive displacement pump componentsAngiographyElectric machineryAir pump

The invention relates to the technical field of mini air pumps, in particular to a flat annular mini air pump of a small sphygmomanometer. The flat annular mini air pump comprises a motor, a connecting plate, a first annular body and a second annular body. The motor is connected with the connecting plate, and the connecting plate is connected with the first annular body and the second annular body. The integral structure of the mini air pump is flat, and usage and storage of an ultra-thin arm type electronic sphygmomanometer are facilitated. Two sets of cylinders can be finish pressurizing through one-circle rotation of the motor, the pressurizing amount is large, and the pressurizing speed is high.

Owner:安徽冠东科技有限公司

Method for detecting content of starch in tobacco

PendingCN114264618AImprove work efficiencyImprove detection efficiencyPreparing sample for investigationColor/spectral properties measurementsBiotechnologyEngineering

The invention discloses a method for detecting the content of starch in tobacco, which belongs to the technical field of tobacco detection and adopts a starch detection device for tobacco for detection. The starch detection device for tobacco comprises a case, a lifting device arranged in the case, and a pressurizing device, a first clamping device, a collecting drawer and a second clamping device which are sequentially arranged on the case from top to bottom, in the detection process, the pressurizing device is controlled through the lifting device, the sintered glass sand core funnel and the volumetric flask are fixed through the first clamping device and the second clamping device respectively, waste liquid is collected through the collecting drawer, then separation and collection of tobacco leaf powder and a liquid reagent in the sintered glass sand core funnel are completed in a matched mode, and the starch content of the collected liquid is measured through a colorimetric method. The method for detecting the starch content in the tobacco is rapid in detection, one detector can treat a plurality of samples at the same time, and the detection effect is remarkably improved.

Owner:中国烟草总公司福建省公司 +1

Bidirectional compression hydraulic press intelligent hydraulic control system

The present invention relates to a bidirectional pressing hydraulic machine intelligent hydraulic control system. Said system includes upper main cylinder, lower main cylinder, valve group, oil line, oil pump and oil tank. The described valve group includes upper and lower main cylinder proportion pump group, upper and lower main cylinder pump outlet valve group, supporting valve group, upper and lower main cylinder control valve group, conversion valve group, upper and lower main cylinder unloading valve group, communication valve group and unloading valve group.

Owner:TIANJIN TIANDUAN PRESS CO LTD

A contact knife automatic brazing equipment

ActiveCN108672873BExtend your lifeLow costHeating appliancesWelding/soldering/cutting articlesEngineeringSoldering

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

Portable soft rock triaxial experiment instrument with adjustable confining pressure

PendingCN114486523AWeakening has little effectReduce the difficulty of operationMaterial strength using tensile/compressive forcesAxial displacementAxial pressure

The invention discloses a portable confining pressure-adjustable soft rock triaxial experiment instrument. The portable confining pressure-adjustable soft rock triaxial experiment instrument comprises a load frame, a confining pressure applying device, an axial pressurizing device and an axial strain metering device, the loading frame is divided into an upper layer and a lower layer, the upper layer is provided with an experimental sample, and the lower layer is provided with an axial loading device; the confining pressure applying device comprises a plurality of clamps, high-strength steel wires and an enclosure structure, the enclosure structure is arranged outside the experimental sample in a sleeving manner, the high-strength steel wires are divided into a plurality of sections, and the sections of the high-strength steel wires are alternately wound outside the enclosure structure clockwise and anticlockwise; steel wire shafts are arranged on the clamps, the two ends of the high-strength steel wires are wound on the steel wire shafts of the corresponding clamps respectively, the clamps are clamped and fixed on the load frame in the radial direction of the experimental sample, and the confining pressure of the high-strength steel wires on the experimental sample can be adjusted by rotating the steel wire shafts; and the axial strain metering device is used for measuring the axial displacement of the experimental sample. The soft rock triaxial experiment instrument has the advantages of being accurate and controllable in confining pressure, capable of providing high confining pressure, convenient to carry, good in economical efficiency and high in axial pressure.

Owner:SHENYANG JIANZHU UNIVERSITY

Adjustable oil-immersed transformer coil restraining device

ActiveCN114512332AEasy to adjust the rotation forceAvoid disorderCoils manufactureHydraulic cylinderRotary stage

The invention discloses an adjustable oil-immersed transformer coil restraining device which comprises a winding iron core, a winding operation table is connected to the bottom of the winding iron core in a clamped mode, a winding rotating table is rotatably connected to the interior of the winding operation table, and a winding motor is fixedly connected to the bottom of the winding rotating table. The outer surface of the winding motor is sleeved with a lifting hydraulic cylinder, the top of the lifting hydraulic cylinder is slidably connected with a resistance adjusting rod, and the top of the winding operation table is fixedly connected with a winding constraint lifting table. When a wire is wound on the outer surface of the winding iron core, the winding iron core can be placed on the top of the winding rotating table, then the winding rotating table is driven by the winding motor to start to rotate, and therefore the winding iron core is driven to start to rotate, and when the rotating force is too large, the resistance adjusting rod can be controlled by the lifting hydraulic cylinder to ascend and descend; and the rotating force of the winding rotating table is controlled, and the effect of conveniently adjusting the wire winding force is achieved.

Owner:安徽九天变压器有限公司

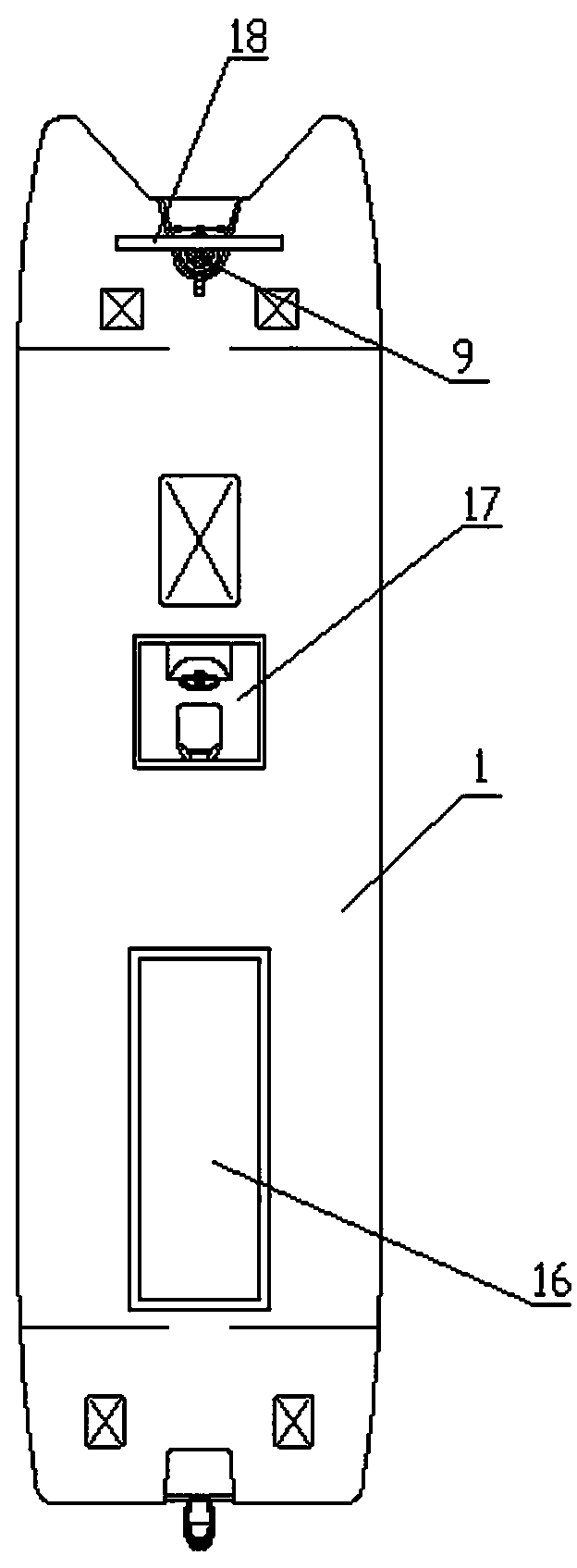

A cyanobacteria salvage and pressurized algae control boat

ActiveCN106638518BReduced activityGood flexibilityWater cleaningWaterborne vesselsWater dischargeControl treatment

The invention relates to a water treatment device, in particular to a blue-green algae salvage and pressurized control ship. The blue-green algae salvage and pressurized control ship is characterized by comprising a ship body, wherein a water feeding main pipe, two pressurization tanks, a water discharging main pipe, an air compressor and a generator set are arranged on the ship body; one end of the water feeding main pipe is connected with a blue-green algae collection pump through a water pipe, and the other end of the water feeding main pipe is connected with the two pressurization tanks through water pipes respectively; a water feeding valve is arranged between the water feeding main pipe and each of the two pressurization tanks; the water discharging main pipe is connected with the two pressurization tanks through water pipes respectively; a water discharging valve is arranged between the water discharging main pipe and each of the two pressurization tanks; the air compressor is connected with the two pressurization tanks through air pipes respectively, and an air feeding valve is arranged between the air compressor and each of the two pressurization tanks; and the generator set is connected with the air compressor and the blue-green algae collection pump through lead wires respectively. The blue-green algae salvage and pressurized control ship is high in flexibility, high in handling capacity and applicable to prevention and control treatment of large-area water blue-green algae outbreak.

Owner:WUXI DELINHAI ENVIRONMENTAL PROTECTION TECH CO LTD

Valve load simulation device with movable valve rod

PendingCN114018567AShorten the verification preparation cycleFast pressurizationMachine valve testingEngineeringStress sensors

The invention provides a valve load simulation device with a movablevalve rod. The simulation device comprises a pressure-bearing chamber, a hydraulic device and a pressure sensor, and is characterized in that the pressure-bearing chamber is connected with the hydraulic device and a to-be-tested test valve body, the test valve body is located above the pressure-bearing chamber, and the hydraulic device injects pressurized liquid into the pressure-bearing chamber; and a hole is formed in the gas cavity of the test valve body, a pressure sensor and a valve rod are installed in the hole, and the valve rod moves under the action of a driving device. The device is simple in structure, low in cost, high in safety and capable of achieving large-range load adjustment of the valve rod of the valve and rapidly forming the test capacity.

Owner:西安长峰机电研究所

Multifunctional safety valve capable of being used for pressure test

InactiveCN106523782AStrong impact resistanceShorten detection timeValve housingsTested timeRapid detection

The invention discloses a multifunctional safety valve capable of being used for a pressure test. The multifunctional safety valve comprises a valve body. A valve element is arranged in the valve body. An air inlet channel is arranged at the lower end of the valve element. An exhaust channel is arranged on one side wall of the valve body. One end of the exhaust channel is connected to the valve element. A through hole is formed in the side wall of the valve body and located in the bottom of the valve body. The through hole communicates with the air inlet channel. According to the multifunctional safety valve, the hole is formed in the safety valve, direct connection of the safety valve and pressurized equipment is achieved, the test time of the safety valve is shortened, the input cost of enterprises is reduced, and the structure of the safety valve is changed, so that the safety valve not only has the conventional functions, but also has the off-line quick detection function.

Owner:王小东

Servo electrohydraulic composite pressure method and press machine thereof

InactiveCN101927578BImprove performanceReduce energy consumptionPress ramNumerical controlPunch press

The invention discloses a servo electrohydraulic composite pressure method, comprising the following steps: 1) arranging a stander; 2) arranging an upper hydraulic device on the stander, 3) arranging a closed ring servo electrohydraulic control system, wherein the closed ring servo electrohydraulic control system is connected with the upper hydraulic device, and controls the work situation of the upper hydraulic device; the invention further discloses a press machine which implements the method; the method provided by the invention uses a servo electrohydraulic technology to replace the traditional electrohydraulic control technology, which has simple manufacturing, high efficiency, little power consumption and high control precision; the position control precision can reach to 0.01 to 0.02 millimeters; the pressing, the tensioning, the de-molding, the full deciding and other functions can be realized simultaneously, so the method has a comparatively high processing flexibility; the press machine provided by the invention is rational in structure, little in volume, stable in work, high in capacity, little in noise, and wide in application range. The advantages of a mechanical punching machine, a hydraulic punching machine and a numerical control are integrated, so the press machine has the advantages of multi-function, low cost, large pressure tonnage, etc.

Owner:东莞市得力仕机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com