A pressure control method of a grinding machine pneumatic servo system

A servo system and pressure control technology, applied in the direction of grinding machine tools, grinding devices, electrical components, etc., can solve the problems of low work efficiency and high workpiece loss rate, and achieve fast pressing speed, high pressing precision and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

[0035] The two most important processes in the process of machining workpieces by grinding machines.

[0036] The pneumatic servo system requires its controlled object to accurately approach the target according to the target value specified in the controller. The target value can be the position of the cylinder or the magnitude of the output force of the cylinder. In the pneumatic servo system, a cylinder is required to stay at a certain position with certain precision requirements, and at the same time its output force must reach the set target value, and certain precision requirements are also required.

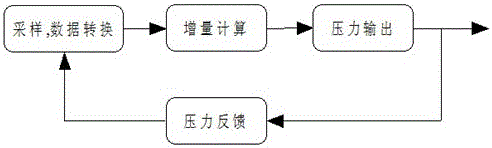

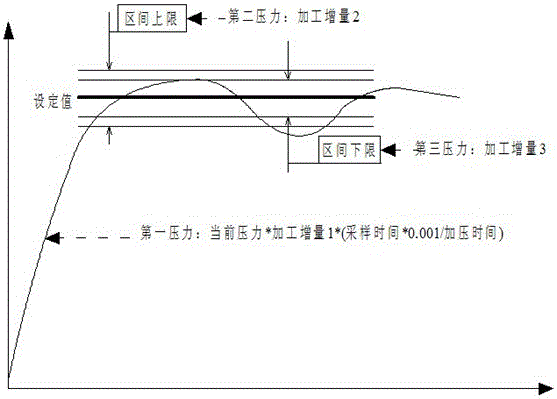

[0037] Such as figure 1 , figure 2 As shown, a pressure control method of a grinder pneumatic servo system, the grinder pneumatic servo system includes a control module, a pressure sampling module, a pressurization module, the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com