Method for detecting content of starch in tobacco

A starch content, tobacco technology, applied in the field of detection of starch content in tobacco, can solve the problems of low detection efficiency, cumbersome operation, etc., and achieve the effect of improving efficiency, improving work efficiency, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

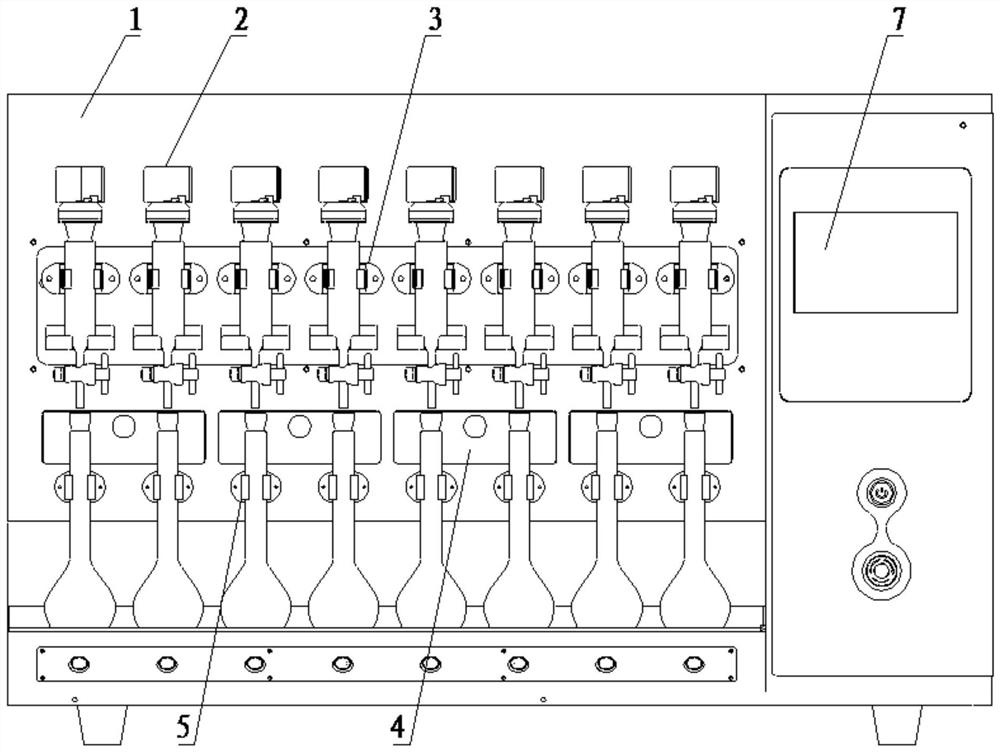

[0044] Please refer to Figure 1 to Figure 5 Shown, embodiment one of the present invention is:

[0045] The method for detecting starch content in tobacco adopts a starch detection device for tobacco to detect;

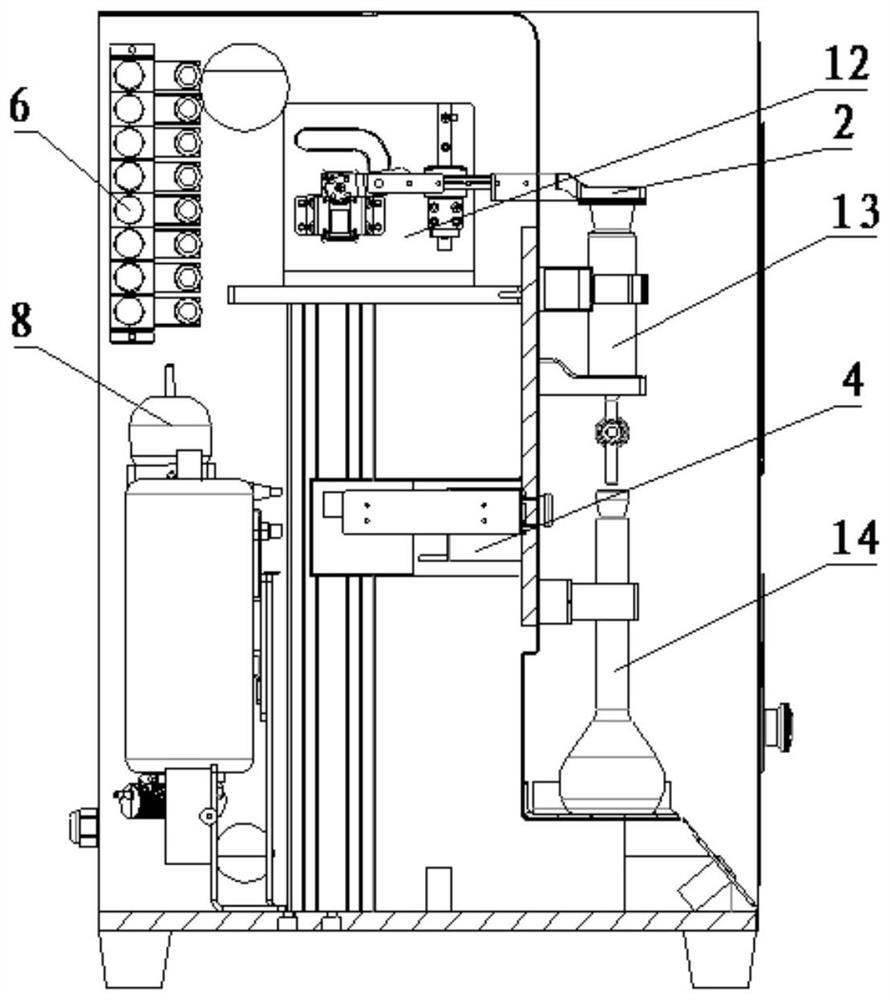

[0046] The tobacco starch detection device includes a cabinet 1, a lifting device 12 arranged in the cabinet 1, and a pressurizing device 2, a first clamping device 3, a collecting drawer 4 and a first clamping device 3 arranged sequentially from top to bottom on the cabinet 1. Two clamping devices 5;

[0047] The lifting device 12 is used to drive the pressurizing device 2 to move along the height direction of the chassis 1; the pressurizing device 2 is provided with an air outlet 201, and the air outlet 201 is arranged toward the first clamping device 3;

[0048]Described cabinet 1 is provided with the groove that can accommodate collection drawer 4, and described collection drawer 4 is provided with handle, and the bottom of described collection drawer 4 is prov...

Embodiment 2

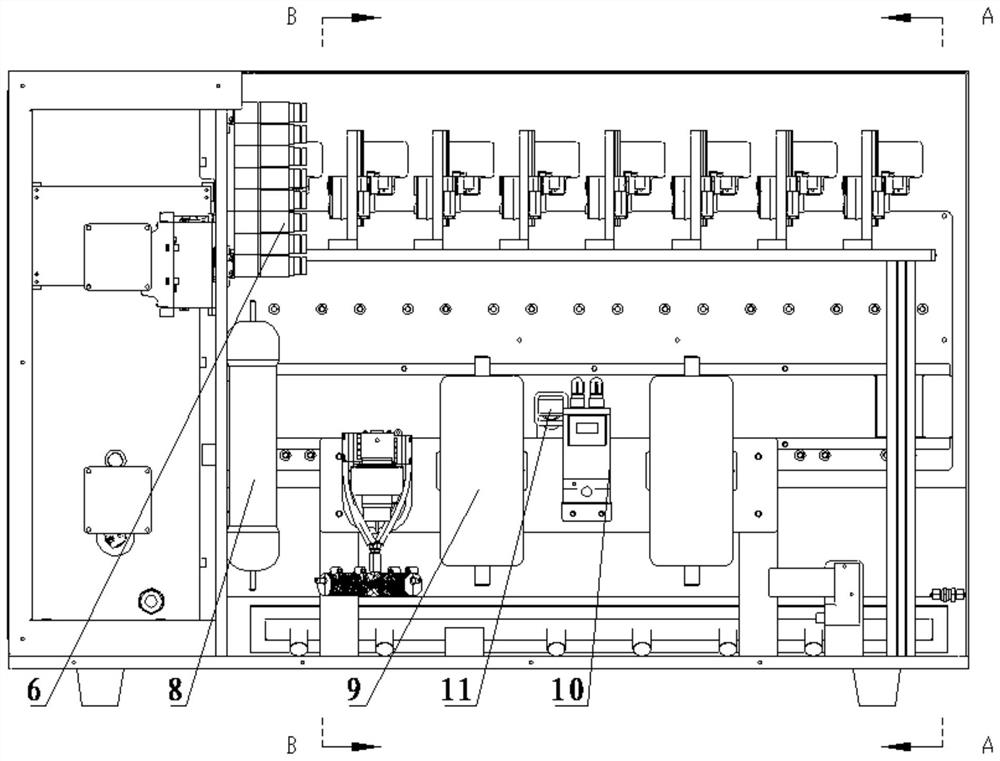

[0055] Please refer to Figure 1 to Figure 5 Shown, embodiment two of the present invention is:

[0056] On the basis of Embodiment 1, the starch detection device for tobacco also includes an air path composed of a solenoid valve 6, a compressed air filter 8, an air storage tank 9, a pressure proportional valve 10 and a pressure switch 11, as well as a hose and a liquid pump A liquid pipeline composed of a liquid storage tank;

[0057] The flexible pipe communicates with the outlet hole;

[0058] The chassis 1 is provided with a processor, and the chassis 1 is provided with a touch screen 7;

[0059] The solenoid valve 6 is used to control the opening and closing of the lifting device 12 ; the processor is electrically connected to the solenoid valve 6 .

[0060] In summary, the detection method provided by the present invention uses a tobacco starch detection device for detection, and can process multiple samples at the same time, or process one sample alone, with high fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com