Production technology for preparing boehmite microcrystalline powder

A production process and technology of microcrystalline powder, applied in the field of ceramic materials, can solve problems such as unfavorable industrial production, large fluctuations in target pressure, and difficulty in controlling the relationship between temperature and pressure, so as to achieve easy control of pressure, reduce production costs, and increase pressure. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

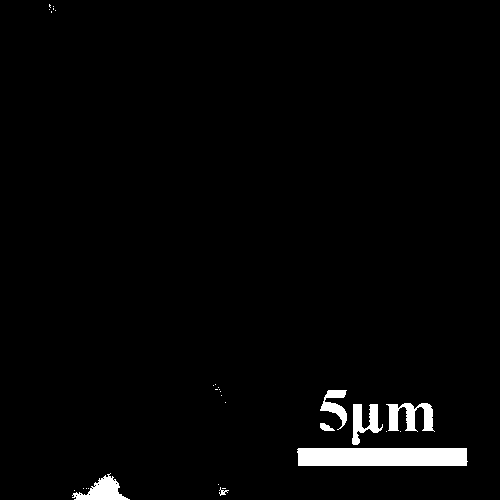

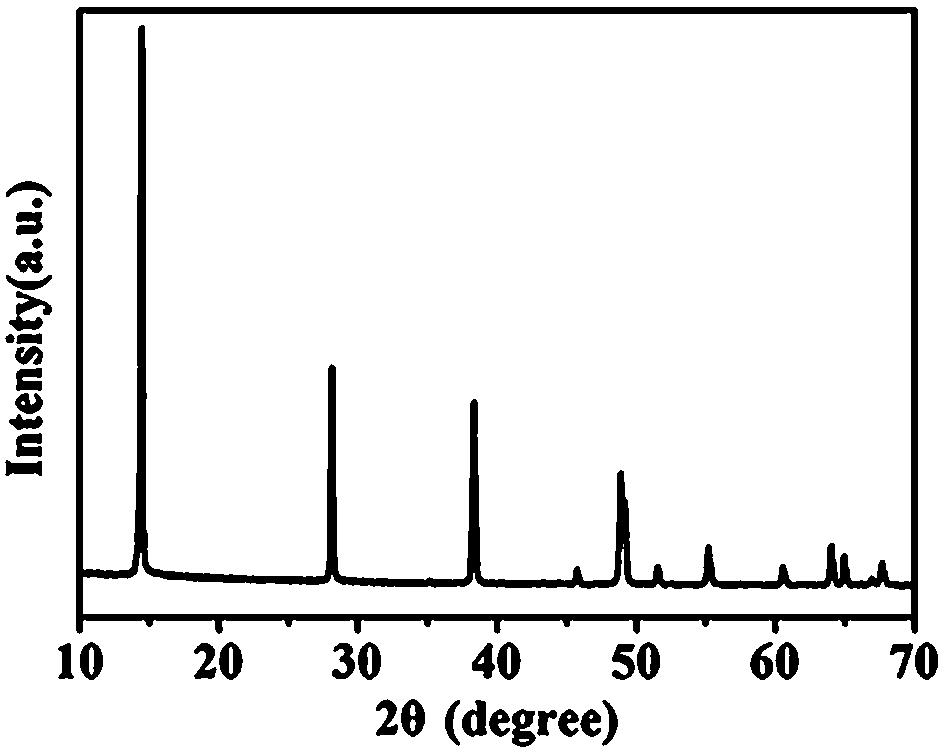

[0020] The raw material alumina trihydrate (D 50 =13μm) and distilled water according to 1Kg: 1.5L were mixed and poured into a high-pressure hydrothermal kettle. During the reaction process, the stirrer was always stirring at a speed of 800rpm, and steam was introduced to heat and pressurize until the pressure reached 2.0MPa. After holding for 3 hours, The slurry was taken out by pressure relief, and the resulting slurry was repeatedly suction-filtered and washed with distilled water until the filtrate was neutral, and the obtained product was dried at 200°C for 10 hours. The particle size of the boehmite microcrystalline powder prepared in this example was D 50 =2.97μm.

Embodiment 2

[0022] The raw material alumina trihydrate (D 50 =13μm) and distilled water according to 1Kg: 1.5L were mixed and poured into a high-pressure hydrothermal kettle. During the reaction process, the stirrer was always stirred at a speed of 800rpm, and steam was introduced to heat and pressurize until the pressure reached 2.5MPa. After holding for 3 hours, The slurry was taken out by pressure relief, and the resulting slurry was repeatedly suction-filtered and washed with distilled water until the filtrate was neutral, and the obtained product was dried at 200°C for 10 hours. The particle size of the boehmite microcrystalline powder prepared in this example was D 50 =3.66μm.

Embodiment 3

[0024] The raw material alumina trihydrate (D 50 =13μm) and distilled water according to 1Kg: 1.5L were mixed and poured into a high-pressure hydrothermal kettle. During the reaction process, the stirrer was always stirring at a speed of 800rpm, and steam was introduced to heat and pressurize until the pressure reached 3.0MPa. After holding for 3 hours, The slurry was taken out by pressure relief, and the resulting slurry was repeatedly suction-filtered and washed with distilled water until the filtrate was neutral, and the obtained product was dried at 200°C for 10 hours. The particle size of the boehmite microcrystalline powder prepared in this example was D 50 =3.87μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com