Multifunctional safety valve capable of being used for pressure test

A multi-function, safety valve technology, applied in the field of safety valves, can solve the problems of short detection time and fast detection speed, and achieve the effects of fast replacement speed, reduction of detection time, and convenient and quick connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

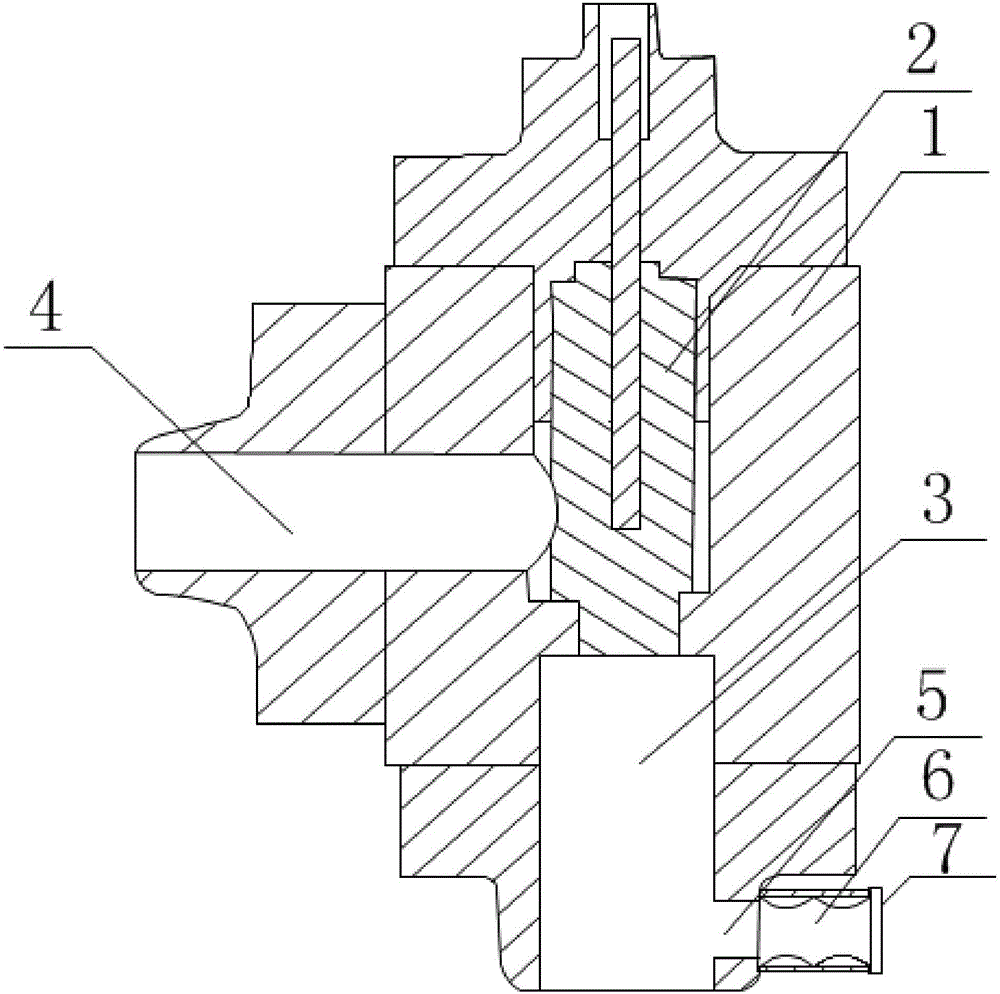

[0025] Such as figure 1 As shown, the present invention is a multifunctional safety valve that can be used for pressure detection, including a valve body 1, a valve core 2 is arranged inside the valve body 1, an inlet passage 3 and an exhaust passage 4 are arranged on the valve body 1, and the inlet passage The passage 3 and the exhaust passage 4 are all connected to the area where the valve core 2 is located. It is characterized in that a through hole 5 is also provided on the side wall of the valve body 1, and the through hole 5 is located at the bottom of the valve body 1. The through hole 5 communicates with the air inlet 3. The side wall of the valve body 1 where the through hole 5 is located is opposite to the side wall of the valve body 1 where the exhaust channel 4 is located with respect to the valve core 2 . The through hole 5 is a circular through hole, and the inner surface of the through hole 5 is a smooth curved surface. The inner surface of the through hole 5 ...

Embodiment 2

[0028] Based on Embodiment 1, the outer end of the through hole 5 is connected with a connecting pipe 6 , the connecting pipe 6 is fixed on the outer wall of the valve body 1 and communicates with the through hole 5 , and the connecting pipe 6 is provided with internal threads. An annular sealing ring 7 is connected to the outer end of the connecting pipe 6 , and the inner wall of the sealing ring 7 is tangent to the outer wall of the connecting pipe 6 . The safety valve and the pressurized pipeline are threaded to facilitate the replacement of the safety valve, and after the pressure test of the safety valve, the pipeline can no longer be equipped with pressurized equipment in the transmission medium, which reduces the installation cost of the pressurized equipment; the pressurized equipment and The safety valve is connected through the connecting pipe. The sealing ring is used to seal the connection between the connecting pipe and the pressurized equipment to avoid pressure ...

Embodiment 3

[0030] Based on the above embodiment, a flow meter is installed on one side wall of the through hole 5 . The flow meter is the same as the actual flow of the pressurized equipment, and the actual pressure of the safety valve can be judged through the flow to further judge the quality of the safety valve. A pressure sensor can be installed on the flowmeter, and the pressure sensor can be connected to the computer to realize self-testing of the actual bearing pressure of the safety valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com