Valve load simulation device with movable valve rod

A technology of load simulation and driving device, applied in the direction of mechanical valve testing, etc., can solve problems such as unfavorable fast application, expensive and complex equipment, complex system, etc., and achieve the effects of shortening the verification preparation period, improving test efficiency, and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

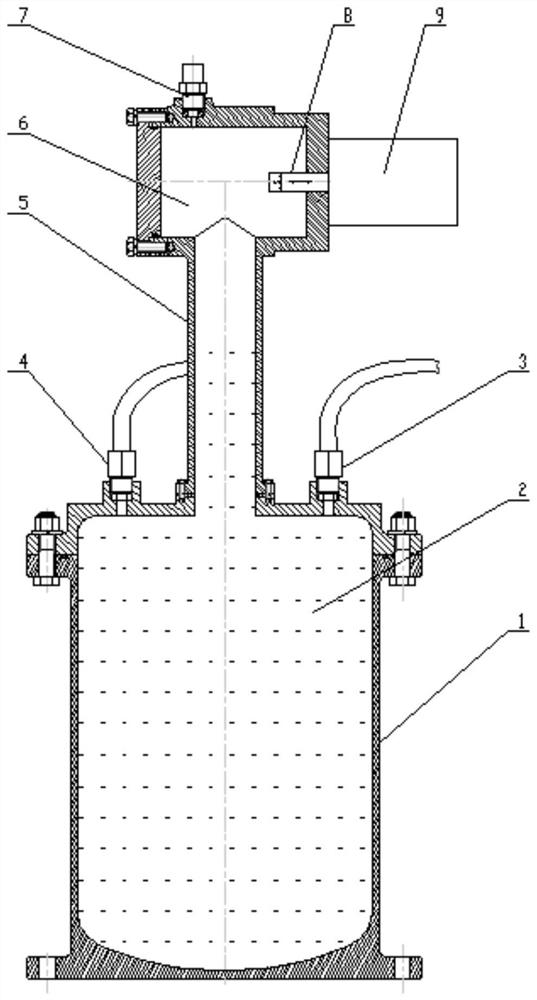

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0015] The invention proposes a valve stem load simulation test device. The load simulation test device is mainly composed of a pressure chamber, a hydraulic device, and a test valve stem mechanism. The upper part of the pressure chamber is an air chamber, and the lower part is a liquid chamber. The rod is installed at the top of the pressure storage chamber. When the hydraulic device is used to pressurize the pressure chamber, the air above the pressure chamber is gradually compressed as the pressure of the pressure chamber increases, but there is still a large amount of air above the pressure chamber. Gas forms a high-pressure gas chamber, and the valve stem bears high-pressure load. According to the pressure-bearing area S of the valve stem and the pressure P of the gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com