Touch tool full-automatic braze welding equipment

A welding equipment and fully automatic technology, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of incompatibility with various specifications of contact knife systems, large fluctuations in welding quality, and poor reliability. The effect of improving efficiency and one-time penetration rate of welding, reducing equipment cost and fast pressing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

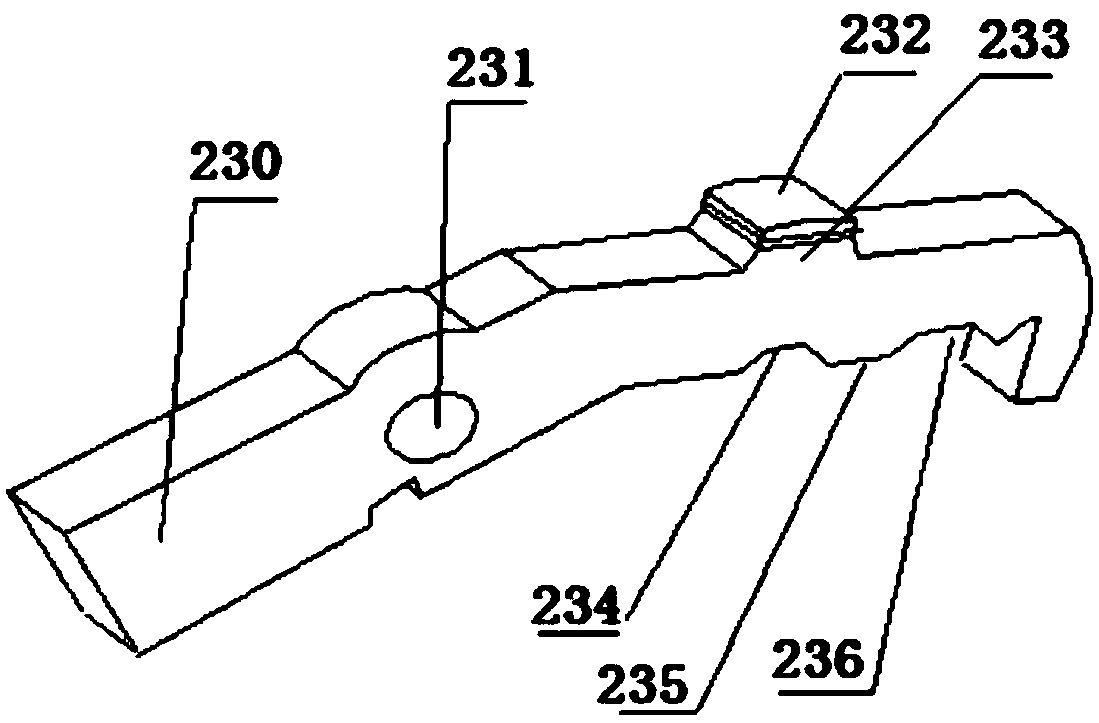

[0041] refer to figure 1 , the welding main body of the present invention is a contact knife 230, and the upper surface of the front section of the contact knife 230 is a trapezoidal upper boss 233; Boss 235 and rear groove 234, rear groove 234 and upper boss 233 positions are opposite up and down, the rear section of contact knife 230 is bent downward, and in the rear part of contact knife 230, there is support hole 231 transversely. The upper boss 233 is a trapezoidal boss, and the top surface is provided with a square groove with a depth less than 1.5mm, which is used to assemble the bottom end surface of the contact 232, the solder piece and the flux (the addition of a square groove in the upper boss 233 of the contact knife 230 is the application for this application. of innovation).

[0042] The purpose of the present invention is to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com