Coke oven heating gas pipeline pressure test device and method

A technology for gas pipelines and coke ovens, which is applied to the field of pressure testing devices for coke oven heating gas pipelines, can solve the problems of low success rate of pressure testing, large loss of accessories, personal safety and production consequences, saving labor input and accelerating pressurization. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

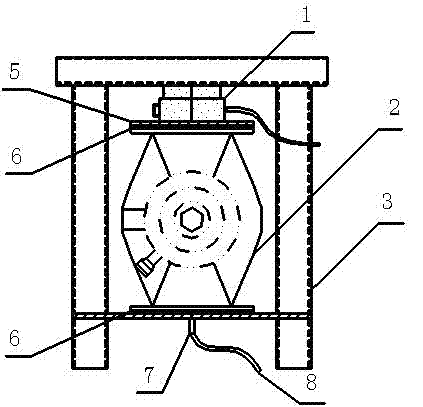

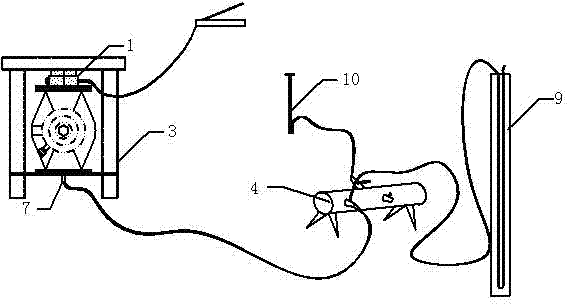

[0033] see now figure 1 and figure 2 , figure 1 It is a structural schematic diagram of the coke oven heating gas pipeline pressure test device of the present invention, figure 2 It is a schematic diagram of the coke oven heating gas pipeline pressure testing device system of the present invention. As shown in the figure, the jack (1) is a commercially available RCS-101 thin hydraulic jack;

[0034] The pressure indication scale (9) is a pressure indication scale with a scale and a length of 2.1m. The pressure indication scale (9) is a pressure scale plate made of a wooden board with a thickness of 10mm, a width of 100mm, and a length of 2200mm. From below to Mark the scale of 0-2m on the top, accurate to cm; then fold the transparent plastic conduit into a U shape and fix it on the scale. One end of the above-mentioned plastic conduit is connected to the inflation hole of the air distribution cylinder (4), and the other end is placed on the top of the scale, and washed ...

Embodiment 2

[0047] Usually, in an engineering project, there are a large number of orifice boxes and cocks in the coke oven gas pipeline system that need to be tested one by one. Therefore, when the time is tight and the test volume is heavy, 3 hydraulic jacks and 3 standard scales can be used. ; 1 special-shaped wrench (for adjusting the rotation angle of the cock), 3 steel fixing frames; 6 5mm thick rubber pads; 1 air distribution cylinder; 1 pump, and related auxiliary tools according to the method of embodiment 1. Carry out pressure testing. The difference from Example 1 is that the air outlet of the air distribution cylinder can be set to three, and a three-way pipe is connected to each air outlet of the air distribution cylinder (4), so that one way of the three-way pipe is connected to the scale One end of (9), the other way connects the inflation hole (7) of the bottom plate of the steel fixed frame (3). The test can be equipped with 2 operators. Since the pressure time of each e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com