Device for continuously fabricating carbon fiber felt production line and technique thereof

A carbon fiber felt and production line technology, applied in fiber processing, heating/cooling fabrics, textiles and paper making, etc., can solve the problems of unstable quality and low efficiency of carbon fiber felt, and achieve the effect of maintaining quality, improving production efficiency, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

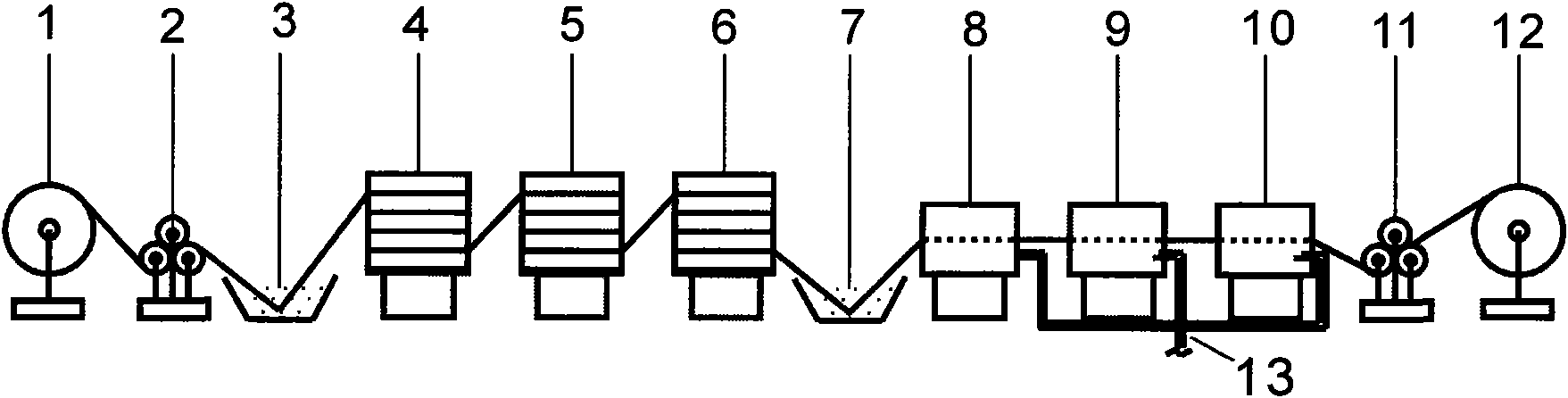

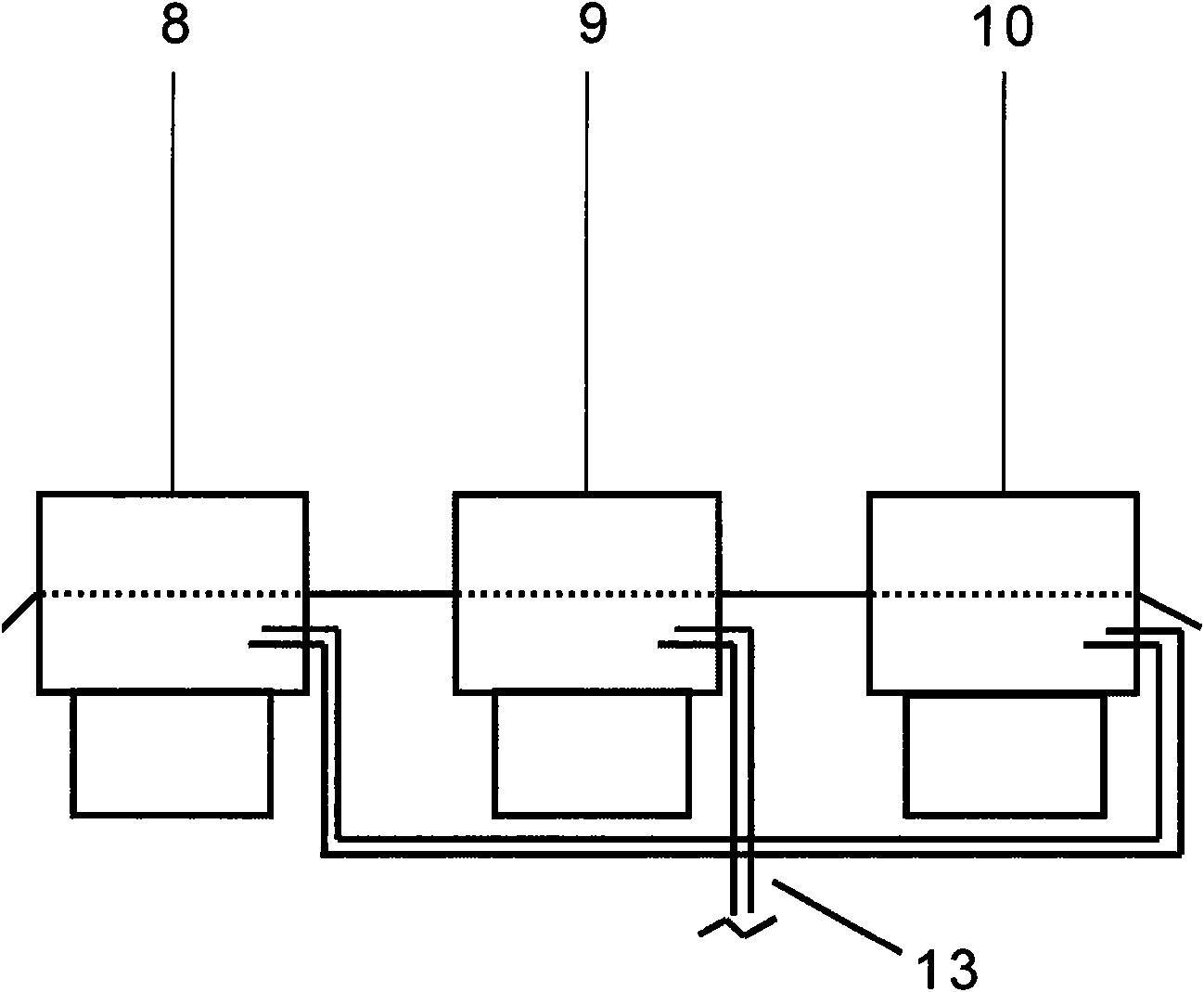

[0019] exist figure 1 with figure 2 The three-dimensional schematic diagram of the equipment and process of the continuous carbon fiber felt production line shown in the figure shows a felt rack 1, a felt machine 2, a felt soaking tank 3, a low-temperature oxidation furnace 4, and a medium-temperature oxidation furnace 5 on the base. , high-temperature oxidation furnace 6, oxidized felt soaking pool 7, low-temperature carbonization furnace 8, medium-temperature carbonization furnace 9, high-temperature carbonization furnace 10, felt collection machine 11, felt collection frame 12 and reactive gas device 13 arranged horizontally in sequence . Each equipment is independently installed on the base, arranged in a straight line with each other, and the felt material rack 1 is connected with a power system, which can drive the felt material rack 1 to rotate; the rotating wheel of the felt machine 2 is a pulley device; the felt material Soaking pool 3 is equipped with nitric acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com