Zeolite coating material with high intercrystalline porosity on the surface of porous silicon carbide support and its preparation

A porous silicon carbide and silicon carbide carrier technology, which is applied in catalyst activation/preparation, inorganic chemistry, molecular sieve catalysts, etc., can solve the problems of unsatisfactory supported zeolite coating, achieve good molecular diffusion performance, improve mass transfer, and load capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

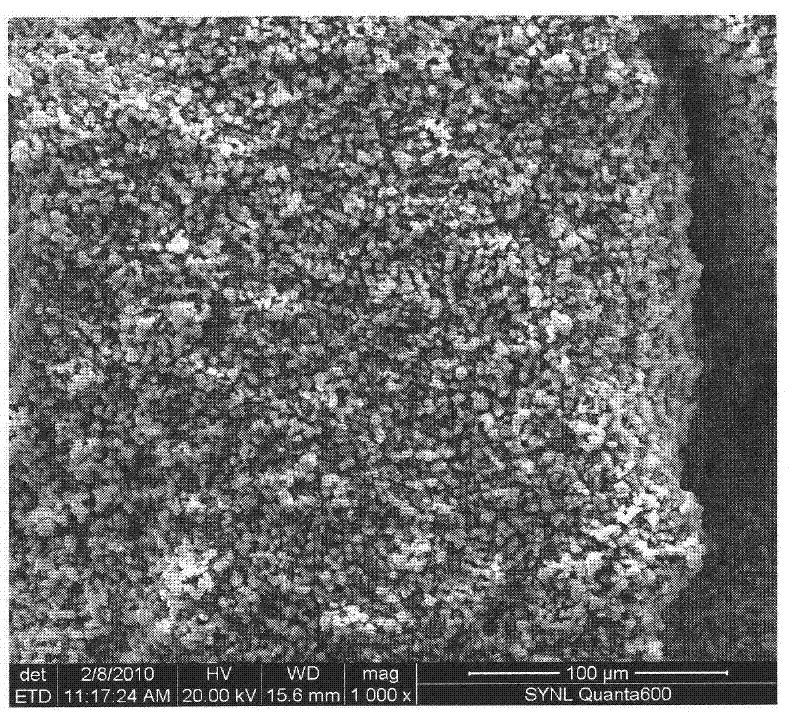

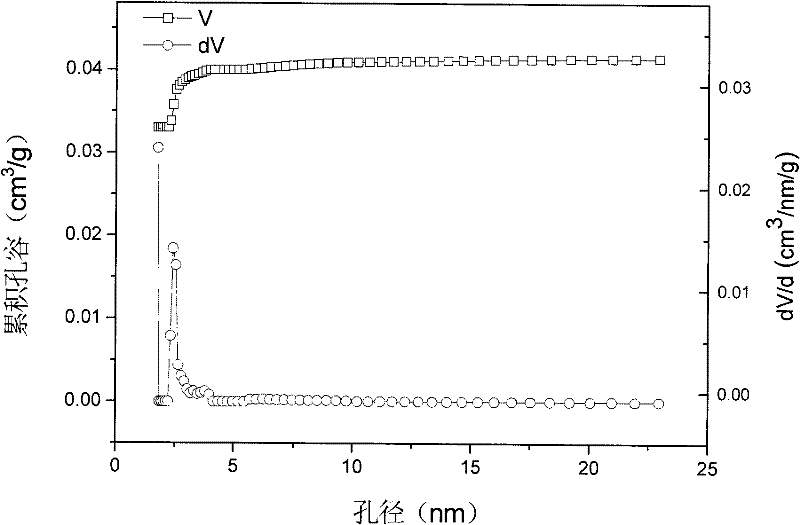

[0035] In this example, the preparation method of the high intercrystalline porosity zeolite coating material on the surface of the foamed silicon carbide carrier:

[0036] First, the surface of the foamed silicon carbide support was modified using a colloidal zeolite seed-directing agent. Mix ethyl orthosilicate, tetrapropylammonium hydroxide, and deionized water in a molar ratio of 1:0.32:29. After the tetraethyl orthosilicate was completely hydrolyzed, the foamed silicon carbide carrier and the above solution were placed in a reaction kettle, and hydrothermally synthesized at 130° C. for 4 hours. A secondary growth solution was prepared, and ethyl orthosilicate, tetrapropylammonium hydroxide, aluminum nitrate, sodium chloride, and deionized water were mixed in a molar ratio of 1:0.15:0.013:0.22:150. The weight ratio of the foamed silicon carbide carrier to the reaction solution is 1:30, and the foamed silicon carbide carrier is fixed at 1 cm away from the bottom of the rea...

Embodiment 2

[0038] In this example, the preparation method of the high intercrystalline porosity zeolite coating material on the surface of the foamed silicon carbide carrier:

[0039] The method for modifying the surface of the foamed silicon carbide carrier with the colloidal zeolite seed crystal directing agent is the same as in Example 1. To prepare a secondary growth solution, mix ethyl orthosilicate, tetrapropylammonium hydroxide, and deionized water in a molar ratio of 1:0.15:150. The weight ratio of the foamed silicon carbide carrier to the reaction solution is 1:30, and the foamed silicon carbide carrier is fixed at 1 cm away from the bottom of the reactor with a polytetrafluoroethylene support frame; the volume of the solution is 55 milliliters, and the volume of the reactor is 100 milliliters. The temperature used for the hydrothermal reaction is 170° C., the time is 48 hours, and the pressure is the autogenous pressure generated by the vaporization of the solution. After the ...

Embodiment 3

[0041] In this example, the preparation method of the high intercrystalline porosity zeolite coating material on the surface of the honeycomb silicon carbide carrier:

[0042] The method for modifying the surface of the honeycomb silicon carbide carrier with the colloidal zeolite seed crystal directing agent is the same as in Example 1. A secondary growth solution was prepared, and ethyl orthosilicate, tetrapropylammonium hydroxide, aluminum nitrate, sodium chloride, and deionized water were mixed in a molar ratio of 1:0.15:0.0065:0.15:190. The weight ratio of the honeycomb silicon carbide carrier to the reaction solution is 1:25, and the honeycomb silicon carbide ceramics is fixed at 1 cm from the bottom of the reactor with a polytetrafluoroethylene support frame; the volume of the solution is 55 milliliters, and the volume of the reactor is 100 milliliters. The temperature used for the hydrothermal reaction is 170° C., the time is 48 hours, and the pressure is the autogenous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com