Recovery processing method and recovery processing device of heat energy

A heat energy recovery and treatment method technology, applied in heating devices, clean heat transfer devices, energy industry, etc., can solve the problems of heat waste, inability to recycle heat energy from waste water, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

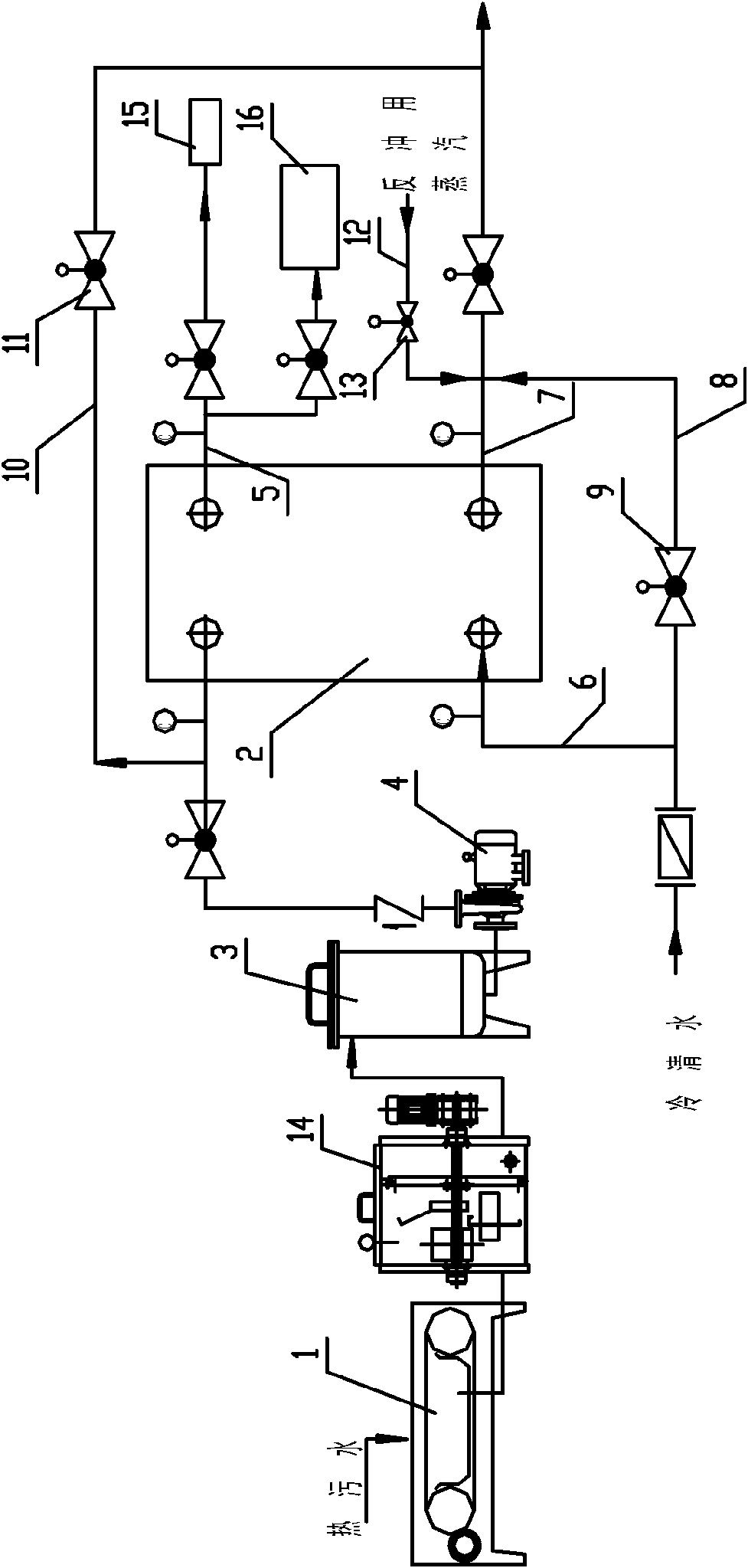

[0021] Example 1. like figure 1 As shown, the thermal energy recovery treatment device of the present invention includes a coarse filter 1 and a plate heat exchanger 2, and the coarse filter 1 adopts a belt filter or other filters. After the coarse filter 1, a rotary disc filter 14 and a precision filter 3 are housed, and the precision filter has another name called a high-precision microporous filter, which is a commercially available conventional product. The precision filter 3 is connected to the plate heat exchanger 2 through the hot water pump 4; on the upper part of the plate heat exchanger 2, there is a hot clean water discharge port 5, which is connected to the hot water use equipment 15 and the hot clean water storage tank 16. A cold water inlet pipe 6 and a sewage discharge pipe 7 are connected to the bottom of the plate heat exchanger 2; a clean water backwash pipe 8 is connected to the sewage discharge pipe 7, and the clean water backwash pipe 8 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com