CPC system having plane type capillary core evaporator and condenser

A technology of capillary core and condenser, which is applied in the field of CPL system, can solve the problems of CPL system start-up difficulty, system temperature and pressure fluctuation, CPL inoperability, etc., and achieve the effect of flexible cooling method, increased reliability, and improved condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

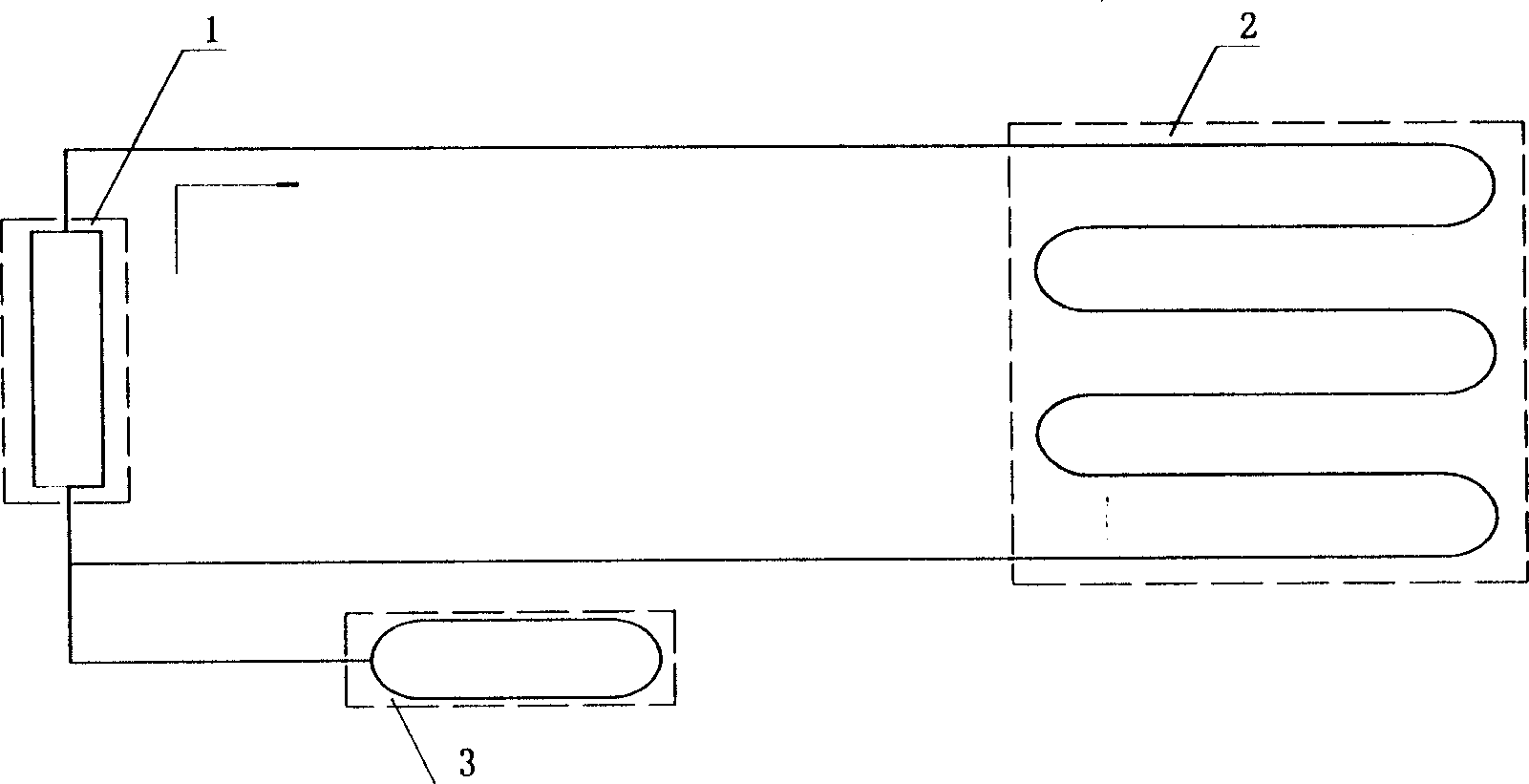

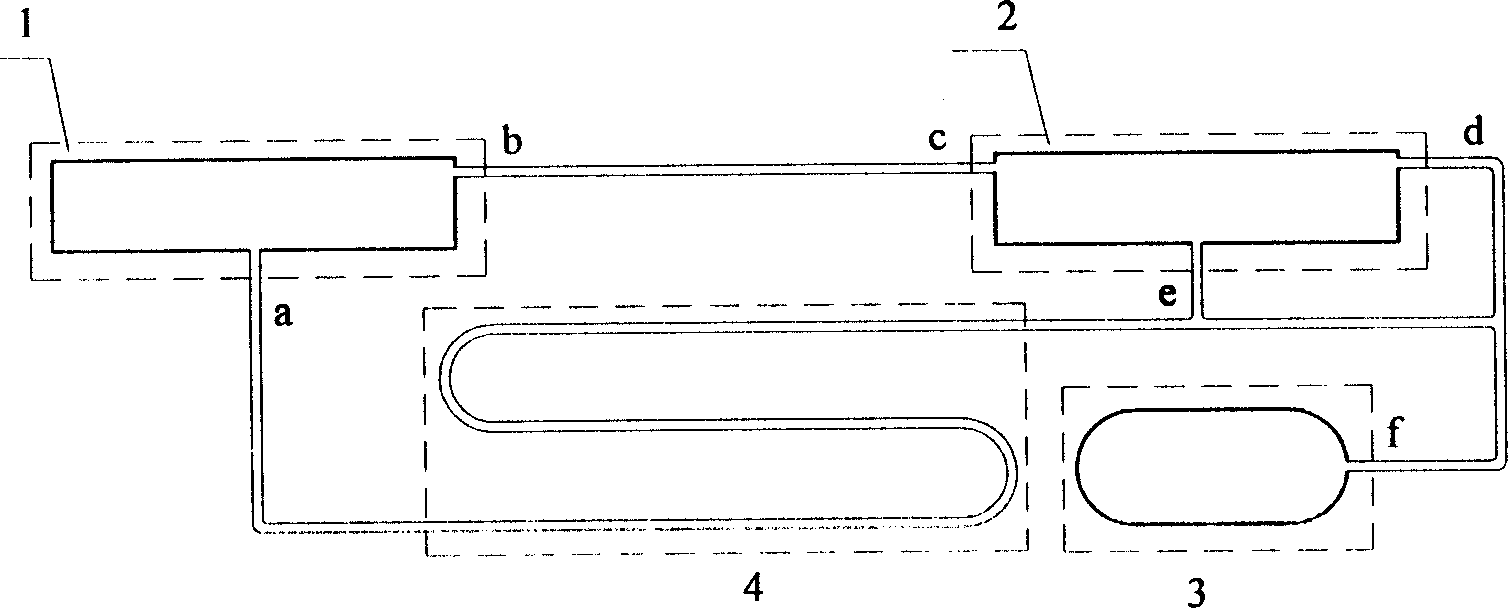

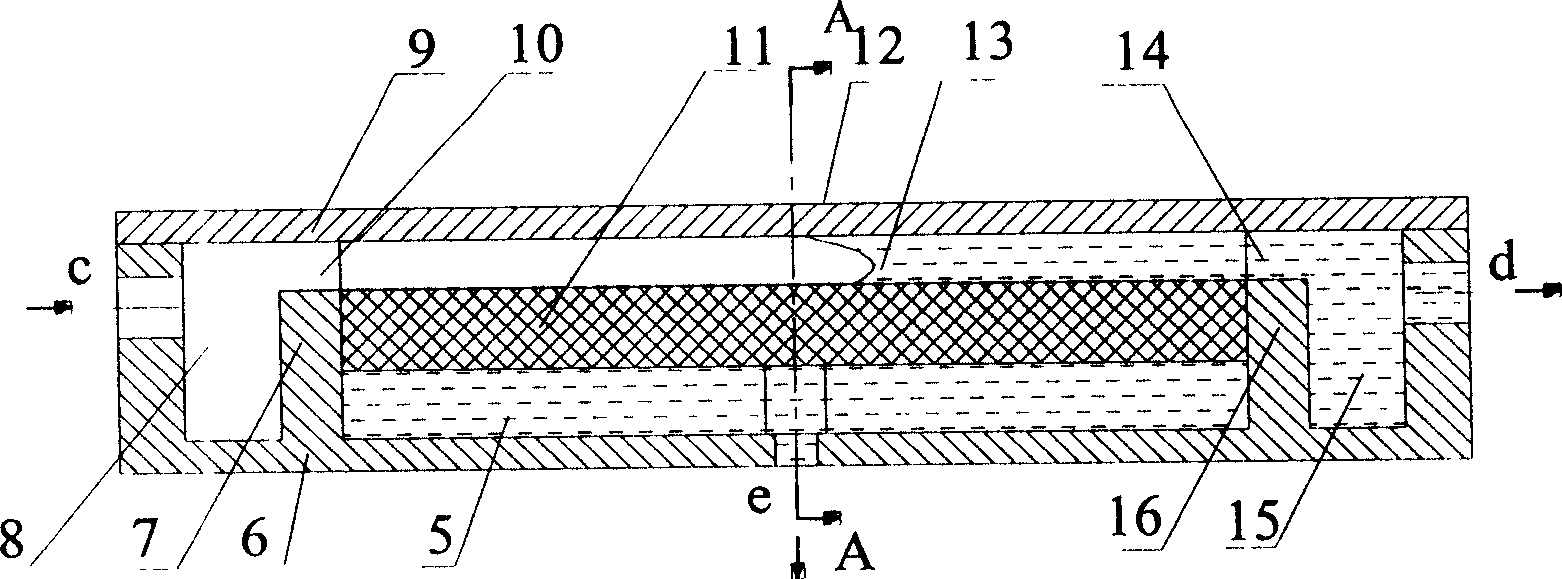

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] Depend on figure 2 As shown, the evaporator 1 is a planar capillary evaporator, and the condenser 2 is a planar capillary condenser; the steam outlet b of the evaporator 1 is connected to the steam inlet c of the condenser 2, and the liquid in the liquid reservoir 3 enters The outlet f is connected to the drain port d of the condenser 2 and the condensate outlet e, and the condensate outlet e of the condenser 2 is connected to the reflux liquid inlet a of the evaporator 1 through the subcooler 4 .

[0034] When the present invention runs stably, the steam produced in the evaporator 1 enters the condenser 2 through the steam outlet b through the steam pipe and enters the condenser 2 through the steam inlet c, and returns through the liquid outlet e through the cooler 4 and the reflux liquid inlet a of the evaporator 1 after condensation The evaporator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com