Method for car clutch face sheet production

A clutch face, automobile technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of low temperature resistance, high cost, environmental pollution, etc., to overcome the problems of low temperature resistance, compact structure, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

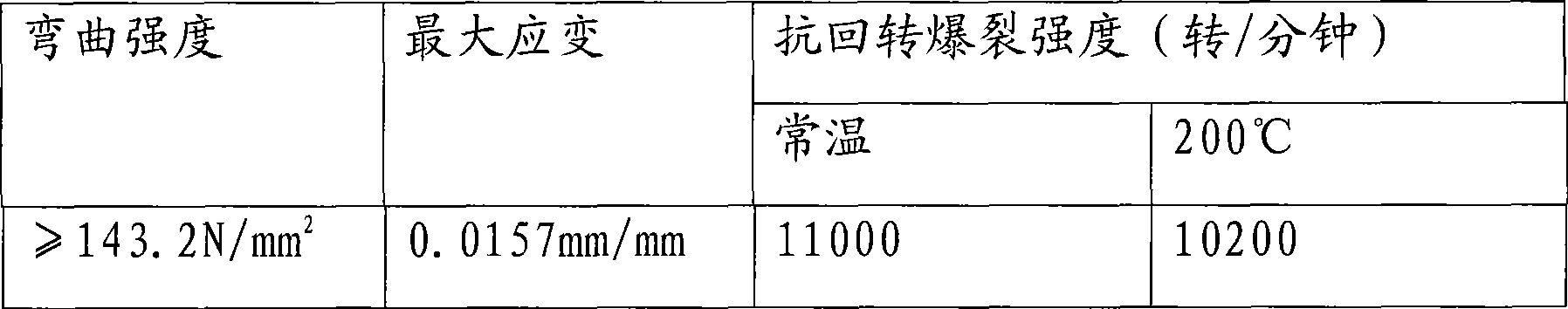

Examples

Embodiment Construction

[0009] 1. Preparation of cord fabric

[0010] First, the sisal fiber is spun and twisted, and the twist of the yarn is controlled at about 120 twists, and the thickness of each twisted yarn is controlled at a diameter of 1.8 to 2.3 mm. While twisting, each strand of yarn is added with an aluminum-nickel alloy wire with a diameter of 0.19 mm, so that the mass ratio of the composite fiber yarn composed of sisal fiber and aluminum-nickel alloy wire is 10:1. The sisal fiber yarn containing Al-Ni alloy wires is then woven into a cord fabric for use. It is also possible to replace the aluminum-nickel alloy metal wire with a diameter of 0.19 mm with a copper wire with a diameter of 0.22 mm, and the mass ratio of the sisal fiber to the copper wire is also 10:1.

[0011] 2. Preparation of slurry

[0012] Put the thermosetting cashew nut shell oil powdery resin, the water-soluble phenolic liquid resin modified by nitrile rubber, and the filler into the mixer, and the filler includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com