Method for improving impregnation effect of fiber cloth enhanced thermoplastic composite material

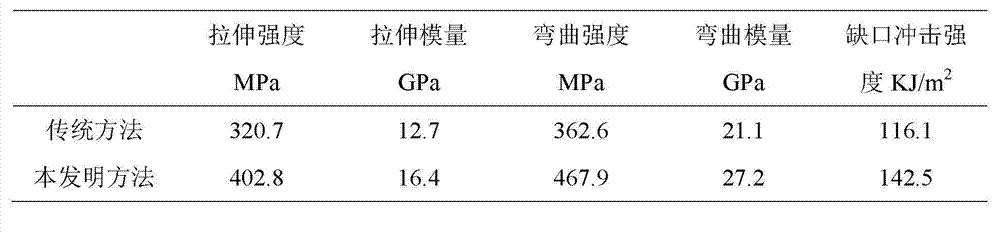

A technology for strengthening thermoplastic and composite materials, which is applied in the field of improving the impregnation effect of fiber cloth reinforced thermoplastic composite materials, can solve the problems of poor impregnation effect, etc., and achieve the effects of improving mechanical properties, improving impregnation effect, and benefiting mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) After drying PPS at 100°C, measure it with KH550 at a mass ratio of 100:1, use a single-screw extruder to melt and extrude at a temperature of 290°C, and obtain a PPS film after shaping by a three-roller calender;

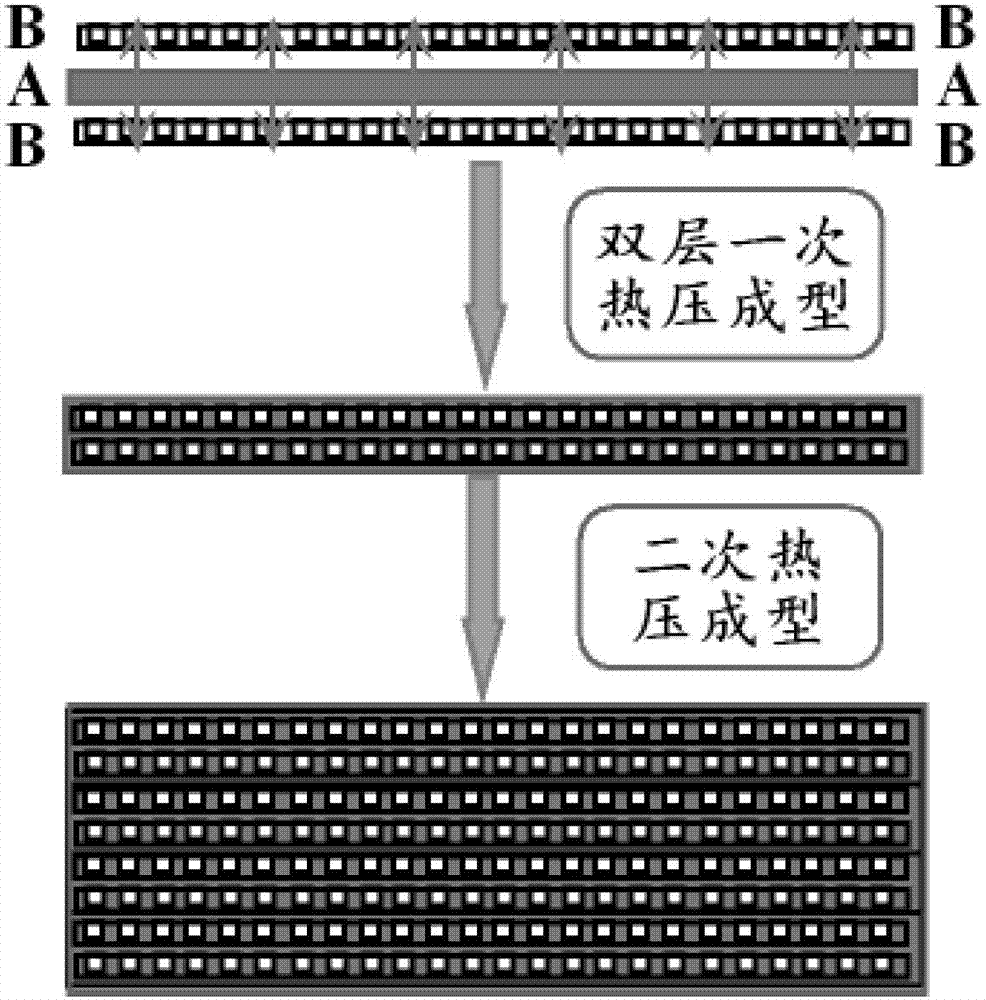

[0035] (2) The above-mentioned diaphragm and fiber cloth are stacked in the order of B layer / A layer / B layer to form a single layer, wherein A layer is the above-mentioned diaphragm, and B layer is glass fiber cloth; Under the condition of 10MPa and 10MPa, a hot press is carried out for 10min to obtain a fiber cloth reinforced polymer-based single-layer sheet prepreg;

[0036] (3) Cut the above-mentioned single-layer sheet prepreg into the required size and superimpose to form a composite laminate, and perform secondary hot pressing for 30 minutes at a temperature of 290°C and 40MPa to obtain a glass fiber cloth with a glass fiber content of 80% / PPS composite material;

[0037] (4) The above-mentioned diaphragm and glass fiber cloth were hot-pressed fo...

Embodiment 2

[0043] (1) After drying PPS at 120°C, measure it with KH560 at a mass ratio of 100:3, use a single-screw extruder to melt and extrude at a temperature of 300°C, and then shape it with a three-roll calender to obtain a PPS film;

[0044] (2) Lay the above diaphragm and fiber cloth in the order of B layer / A layer / B layer to form a single layer, wherein A layer is the above diaphragm and B layer is basalt fiber cloth; Under the condition of 8MPa and 8MPa, a hot press is carried out for 8min to obtain a fiber cloth reinforced polymer-based single-layer sheet prepreg;

[0045] (3) The above-mentioned single-layer sheet prepreg is cut into the required size and then superimposed to form a composite laminate, which is subjected to secondary hot pressing for 25 minutes at a temperature of 300°C and 35MPa to obtain a basalt fiber cloth with a basalt fiber content of 75% / PPS composite material;

[0046] (4) The above-mentioned diaphragm and basalt fiber cloth were hot-pressed for 25 m...

Embodiment 3

[0051] (1) After drying PPS and PA10T at 130°C, measure them with KH560 at a mass ratio of 50:50:5, use a single-screw extruder to melt and extrude at a temperature of 350°C, and then shape it with a three-roll calender to obtain PPS / PA10T diaphragm;

[0052] (2) The above-mentioned diaphragm and fiber cloth are stacked in the order of B layer / A layer / B layer to form a single layer, wherein A layer is the above-mentioned diaphragm and B layer is carbon fiber cloth; Under the condition of 5MPa, carry out a hot pressing for 5 minutes to obtain a fiber cloth reinforced polymer-based single-layer sheet prepreg;

[0053] (3) Cut the above-mentioned single-layer sheet prepreg into the required size and superimpose to form a composite laminate, and carry out secondary hot pressing at a temperature of 350°C and 30MPa for 20 minutes to obtain a carbon fiber cloth / PPS / with a carbon fiber content of 60%. PA10T composite material;

[0054] (4) The above-mentioned diaphragm and carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com