Preparation apparatus of continuous fiber reinforced thermoplastic resin prepreg tape, and its application

A technology for strengthening thermoplastic and continuous fibers, applied in the direction of coating, can solve the problems of inability to prepare prepreg tapes, limited processing temperature, etc., and achieve the effect of improving the impregnation effect, expanding the range, and improving the range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

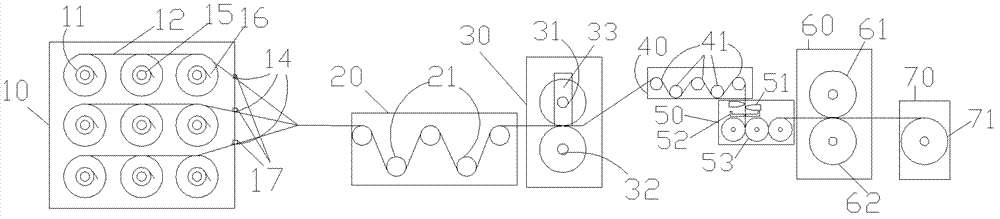

[0066] (1) The continuous glass fiber roll is installed on the spindle 13 of the creel 10, and the glass fiber is pulled through the wire guide hole installed on the head of the creel, and the glass fiber drawn through the wire guide hole is passed through the fiber tow tension adjusting device 20. , so that the glass fibers are arranged in parallel and evenly, so as to avoid the mutual intersection and wear between the glass fibers. Then the glass fibers arranged in parallel pass through the pulling device 30 to exert a certain pulling force on the glass fibers. After passing through the fiber dispersion tension adjusting device 40 , the glass fibers are dispersed and stressed more uniformly, and then enter the dipping compound device 50 .

[0067] (2) The dispersed continuous glass fibers enter the dipping and compounding device 50 . Adjust the running speed of the continuous fiber to 3m / min, adjust the oxygen pressure to 0.50MPa, adjust the gas pressure to 0.08MPa, adjust ...

Embodiment 2

[0071] (1) The continuous carbon fiber roll is installed on the spindle 13 of the creel 10, and the carbon fiber is pulled through the wire guide hole installed on the head of the creel, and the carbon fiber drawn through the wire guide hole passes through the fiber tow tension adjustment device 20, so that the carbon fiber Arranged in parallel and evenly to avoid cross and wear between carbon fibers. Then, the carbon fibers arranged in parallel pass through the pulling device 30 to apply a certain pulling force to the carbon fibers. After passing through the fiber dispersion tension adjusting device 40 , the carbon fibers are dispersed and stressed more uniformly, and then enter the dipping compound device 50 .

[0072] (2) The dispersed continuous carbon fiber fibers enter the dipping and compounding device 50 . Adjust the running speed of the continuous fiber to 4m / min, adjust the oxygen pressure to 0.52MPa, adjust the gas pressure to 0.09MPa, adjust the carrier gas pressu...

Embodiment 3

[0076] (1) The continuous boron fiber roll is installed on the spindle 13 of the creel 10, the boron fiber is pulled through the wire guide hole installed in the head of the creel, and the boron fiber drawn through the wire guide hole is passed through the fiber tow tension adjustment device 20 , so that the boron fibers are arranged in parallel and evenly, so as to avoid the mutual intersection and wear between the boron fibers. Then the boron fibers arranged in parallel pass through the pulling device 30 to exert a certain pulling force on the boron fibers. After passing through the fiber dispersion tension adjusting device 40 , the boron fibers are dispersed and stressed more uniformly, and then enter the dipping compound device 50 .

[0077] (2) The dispersed continuous boron fibers enter the dipping and compounding device 50 . Adjust the running speed of the continuous fiber to 5m / min, adjust the oxygen pressure to 0.54MPa, adjust the gas pressure to 0.09MPa, adjust the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com