Continuous long fiber-reinforced thermoplastic resin and its preparation method and molding equipment

A technology for reinforcing thermoplastics and thermoplastic resins, which is applied in the field of continuous long fiber reinforced thermoplastic resins. It can solve the problems of low fiber bundle temperature, affecting thermoplastic resin impregnation, and poor dispersion and impregnation effects, so as to improve dispersion effect, fiber impregnation and dispersion efficiency. High, the effect of increasing the contact temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

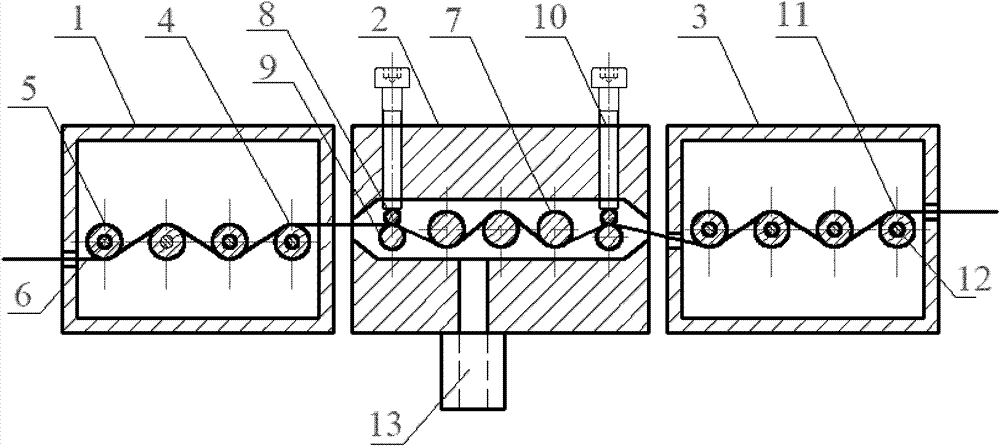

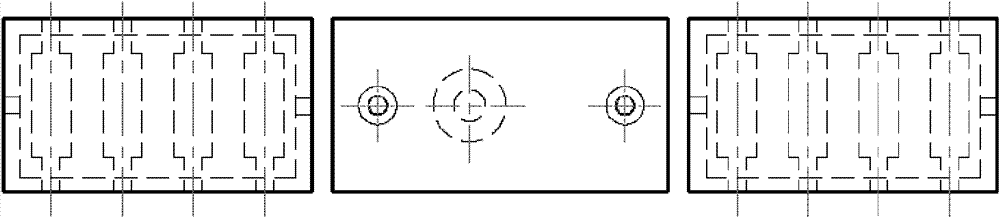

[0027] Such as figure 1 with figure 2 As shown, a molding equipment for producing continuous long fiber reinforced thermoplastic resin, the molding equipment sequentially includes along the extrusion direction: fiber preheating device 1, melt impregnation mold 2 and secondary rolling device 3; fiber preheating device 1 consists of Composed of 4 equally spaced dispersing rollers, the diameter of the dispersing rollers is 45mm, and the distance between two adjacent dispersing rollers in the horizontal direction is 45mm. The dispersing roller 4 is provided with a heat source by the electric heating rod 5 of the dispersing roller at the core; The dipping mold 2 is made up of 5 equally spaced tension rollers 7, the diameter of the tension rollers is 50mm, and the distance between two adjacent tension rollers in the horizontal direction is 50mm; the first group of tension rollers and the last group of tension rollers are composed of The upper tension roller 8 and the lower tension...

Embodiment 2

[0029] Such as figure 1 with figure 2As shown, a molding equipment for producing continuous long fiber reinforced thermoplastic resin, the molding equipment sequentially includes along the extrusion direction: fiber preheating device 1, melt impregnation mold 2 and secondary rolling device 3; fiber preheating device 1 consists of Composed of 4 equally spaced dispersing rollers, the diameter of the dispersing roller is 100 mm, and the distance between two adjacent dispersing rollers in the horizontal direction is 100 mm. The dispersing roller 4 is provided with a heat source by the electric heating rod 5 of the dispersing roller at the core; The dipping mold 2 is made up of 5 equally spaced tension rollers 7, the diameter of the tension rollers is 100mm, and the distance between two adjacent tension rollers in the horizontal direction is 60mm; the first group of tension rollers and the last group of tension rollers are composed of The upper tension roller 8 and the lower tens...

Embodiment 3

[0031] 1) Utilize the molding equipment for the production of continuous long fiber reinforced thermoplastic resin prepared in Example 1, alternately bypass the four dispersing rollers 4 of the fiber preheating device 1 with a bundle of continuous long fiber bundles 6, and electrically heat the dispersing roller core Under the action of rod 5, the set preheating temperature of 180°C is reached, and preliminary dispersion is obtained at the same time;

[0032] 2) The continuous long fiber bundle 6 that has been preheated and dispersed in step 1) is introduced into the melt impregnation mold 2, and alternately bypasses the five tension rollers 7 in the cavity; at the same time, the thermoplastic resin melt is fed by the extruder connecting device 13 Enter the molten impregnation mold 2; by adjusting the adjustment screw 10 on the molten impregnation mold 2, adjust the calendering gap between the upper tension roller 8 and the lower tension roller 9 to be 0.1mm, and the thermoplas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com