Preparation method of olefin polymerization catalyst component and prepared olefin polymerization catalyst component

An olefin polymerization and catalyst technology, applied in the field of olefin polymerization, can solve the problems of high cost and high price, and achieve the effects of narrow particle size distribution, reduced toluene content, high activity and stereospecificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

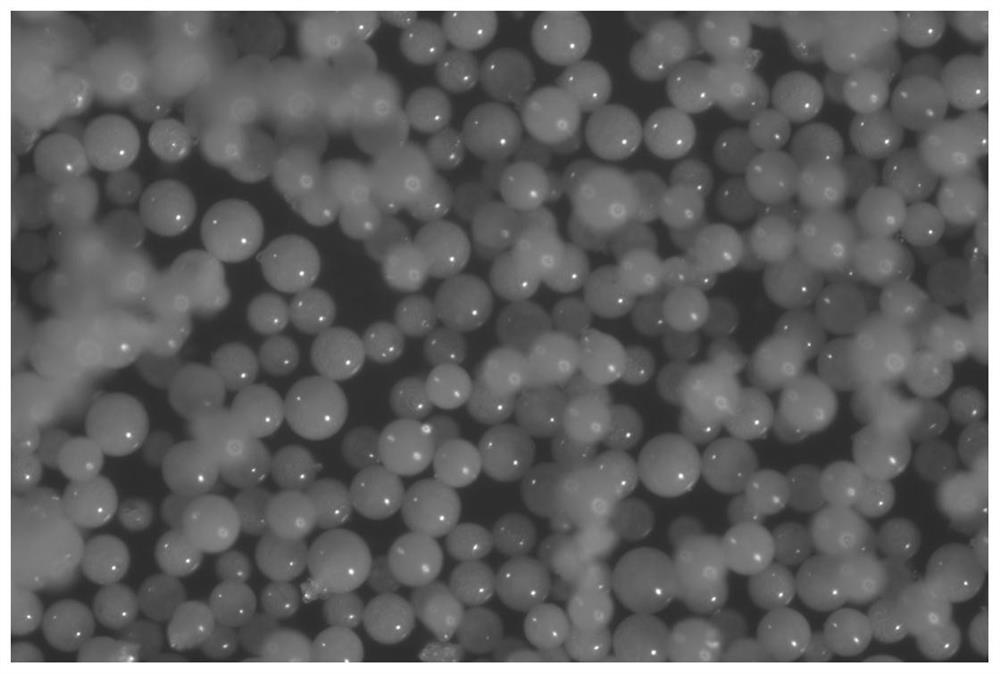

Embodiment 1

[0105] In the reaction kettle that has been repeatedly replaced by high-purity nitrogen, add 10.86g of anhydrous magnesium chloride, 65g of toluene, 11.13g of epichlorohydrin, and 33.8g of tributyl phosphate in sequence, and keep stirring at 300RMP for 2 hours at a temperature of 60°C. . Then 3.8 g of phthalic anhydride were added and the temperature at 60° C. was maintained for a further 1 hour. Cool down to 40°C, then add a mixture of 89.8g decane and 5.7g T602, increase stirring to 500 RMP, and continue to maintain for 1 hour. Then the solution was cooled to 12° C., 142.1 ml of titanium tetrachloride was added dropwise, and continued for 1 hour after the addition was completed. The temperature was gradually raised to 80°C over 3 hours and held there for 1 hour. The mother liquor was filtered, and the solid was washed twice with hot toluene and then twice with hexane, and then dried to obtain a solid. Among them, the average particle diameter D50 of solid matter is 35.4 μ...

Embodiment 2

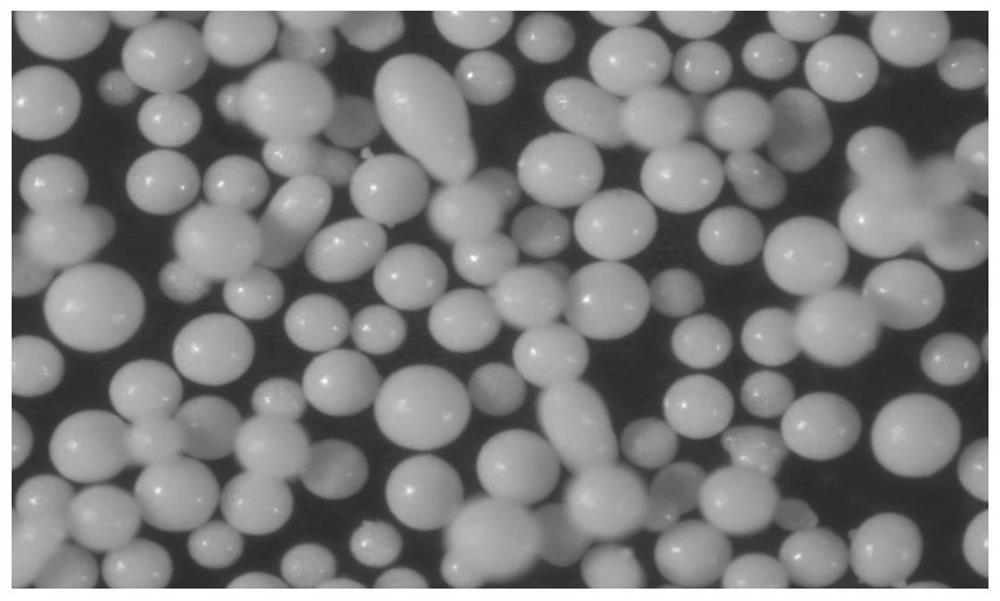

[0107] In the reaction kettle that has been repeatedly replaced by high-purity nitrogen, 10.86g of anhydrous magnesium chloride, 74.54g of toluene, 11.13g of epichlorohydrin, and 36.8g of tributyl phosphate were added in sequence, and kept stirring at 300 RMP for 2 Hour. Then 3.8 g of phthalic anhydride were added and the temperature at 60° C. was maintained for a further 1 hour. Cool the solution to 12°C, add 142.1ml of titanium tetrachloride dropwise, increase the stirring to 500 RMP, add a mixture of 5.7g of T602 and 109.1g of food grade No. 26 white oil, continue for 1 hour after the dropwise addition, and gradually heat up to 80°C. The mother liquor was filtered, and the solid was washed twice with hot toluene and then twice with hexane, and then dried to obtain a solid. Among them, the average particle diameter D50 of solid matter is 45.2 μm, and the SPAN value is 0.82.

Embodiment 3

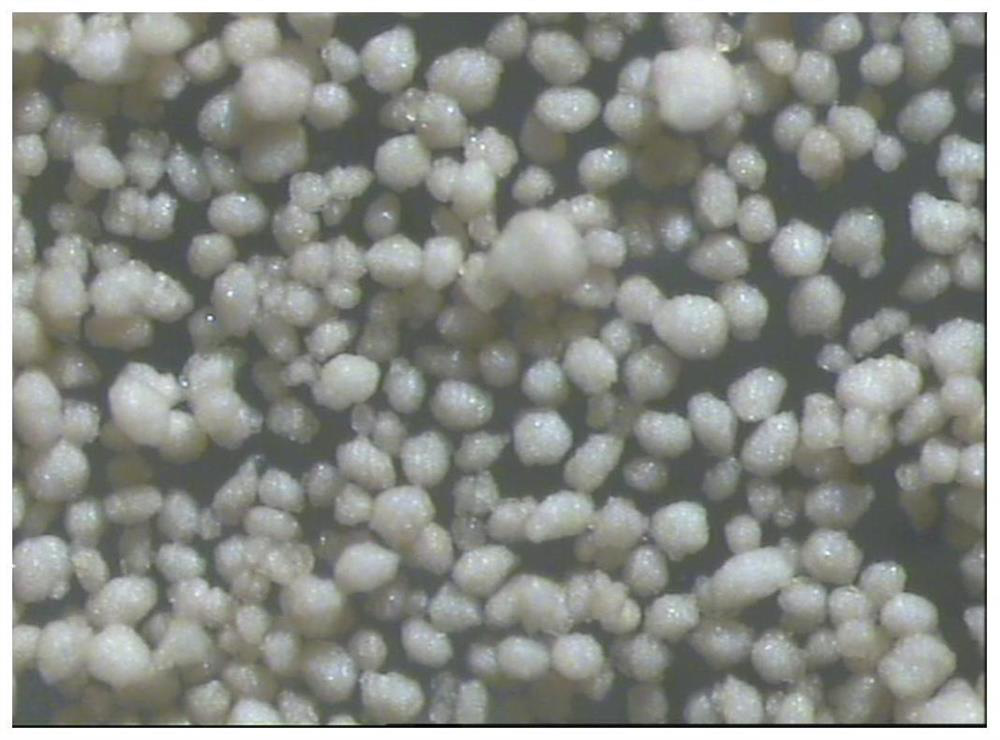

[0109] In the reaction kettle that has been repeatedly replaced by high-purity nitrogen, 10.86g of anhydrous magnesium chloride, 57.22g of toluene, 11.13g of epichlorohydrin, and 36.8g of tributyl phosphate were sequentially added, and kept stirring at 300 RMP for 2 Hour. Then 2.85 g of T602 diluted with 3.8 g of phthalic anhydride and 17.32 g of toluene were added and the temperature was maintained at 60° C. for an additional hour. Cool the solution to 30°C, raise the stirring to 500 RMP, and start to drop 142.1ml of titanium tetrachloride, and a mixture of 124.1g of food grade No. 100 white oil and 2.85g of T602 respectively, and continue for 1 hour and 3 hours after the addition is completed The temperature was gradually raised to 80°C. The mother liquor was filtered, and the solid was washed twice with hot toluene and then twice with hexane, and then dried to obtain a solid. Among them, the average particle diameter D50 of solid matter is 60.4 μm, and the SPAN value is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com