Equipment and method for impregnating continuous long fiber reinforced thermoplastics

A technology for enhancing thermoplastics and impregnating equipment, which is applied in the impregnation of continuous long fiber reinforced thermoplastics and impregnation equipment for continuous long fiber reinforced thermoplastics. Rotation and other issues, to increase interaction, improve impregnation effect, and ensure easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

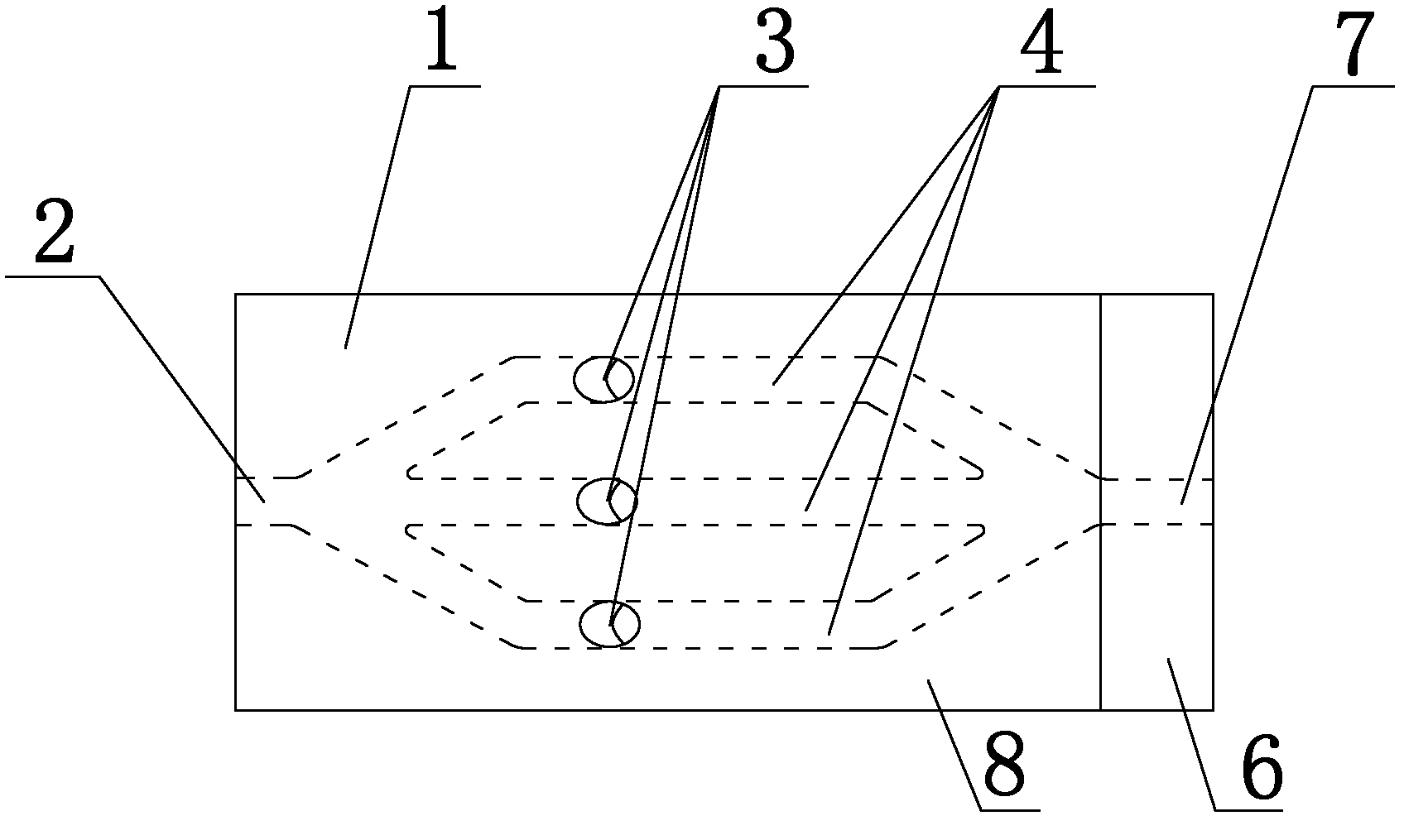

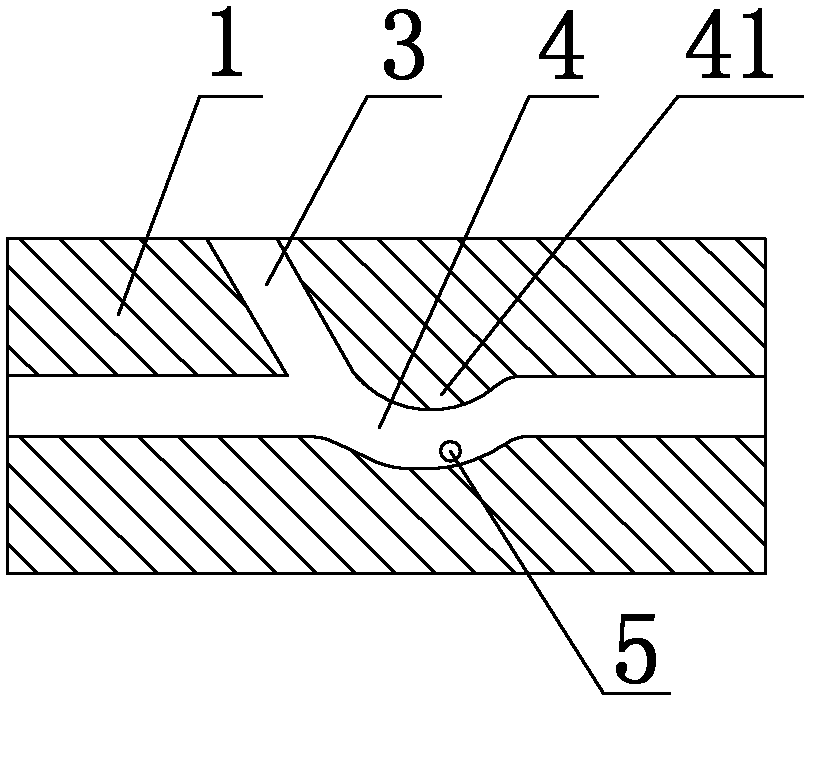

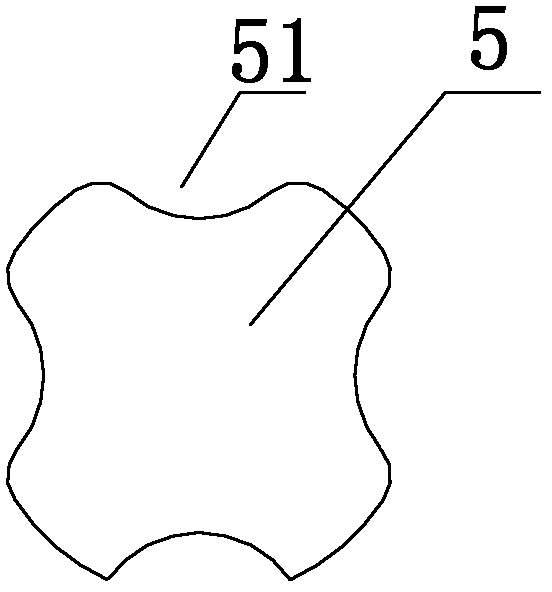

[0027] like figure 1As shown, the present invention includes an equipment outer body 1 , the upstream end of the equipment outer body 1 is provided with a melt inlet 2 , the downstream end of the equipment outer body 1 is provided with an extrusion port 7 , and the inside of the equipment outer body 1 An immersion channel 4 is provided, and the two ends of the immersion channel 4 are respectively communicated with the melt inlet 2 and the extrusion port 7. At least two of the immersion channels 4 are arranged in parallel. The side wall of 1 is provided with the same number of long fiber inlets 3 as the impregnation channels 4 , and the long fiber inlets 3 are respectively communicated with each impregnation channel 4 . The upstream end of the outer body 1 of the equipment is the end of the feed, which is based on the flow direction of the melt; similarly, the downstre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com