A high-viscosity polymer polycondensation reactor based on a combined stirring mechanism

A technology of polycondensation reactor and stirring mechanism, which is applied in chemical/physical/physicochemical stationary reactors, mixers with rotating stirring devices, mixers, etc., which can solve the problem of longer production process, increased investment costs and production costs , lengthening of residence time, etc., to achieve the effect of mixing, increasing production capacity and product range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1 (ring disc stirrer+spiral blade stirrer)

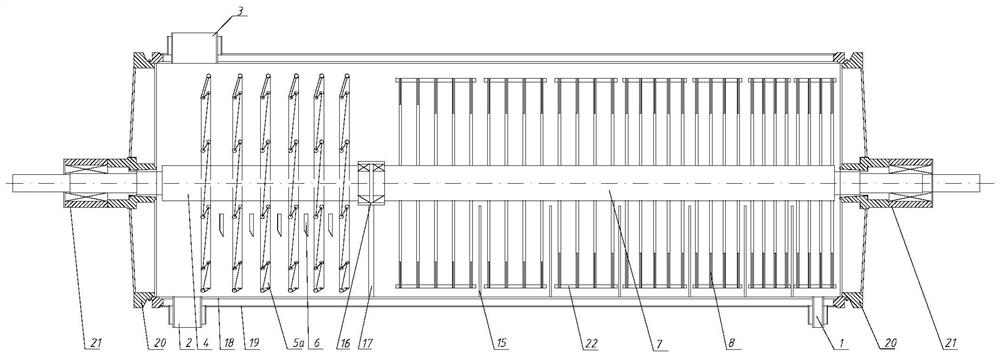

[0075] Such as figure 1 As shown, a high-viscosity polymer polycondensation reactor includes a horizontal cylindrical shell and a combined stirring mechanism located in the horizontal cylindrical shell. The bottom ends of the horizontal cylindrical shell are respectively equipped with feed Port 1 and discharge port 2, and a gas phase port 3 is also provided on the side of the discharge port on the horizontal cylindrical shell. The horizontal cylindrical shell includes an inner cylinder 18, a jacket cylinder 19 (which can be heated by a heat medium) arranged on the outside of the inner cylinder, and end caps 20 arranged at both ends of the inner cylinder and the jacket cylinder; The end cover is provided with a rotating shaft sleeve 21 for sealing and supporting the rotating shaft. The cross section of the inner cylinder is circular, and the centerline of the combined stirring mechanism is lower than the centerlin...

Embodiment 2

[0081] Embodiment 2 (cage frame type mesh pan stirrer + helical blade type tube pan stirrer)

[0082] The difference between this embodiment and embodiment 1 is:

[0083] The cross-section of the inner cylinder is a shape formed by connecting the upper and lower sides of a rectangle with a semicircle of the same radius, and the centerline of the combined stirring mechanism is concentric with the centerline of the lower semicircle in the cross-section of the inner cylinder.

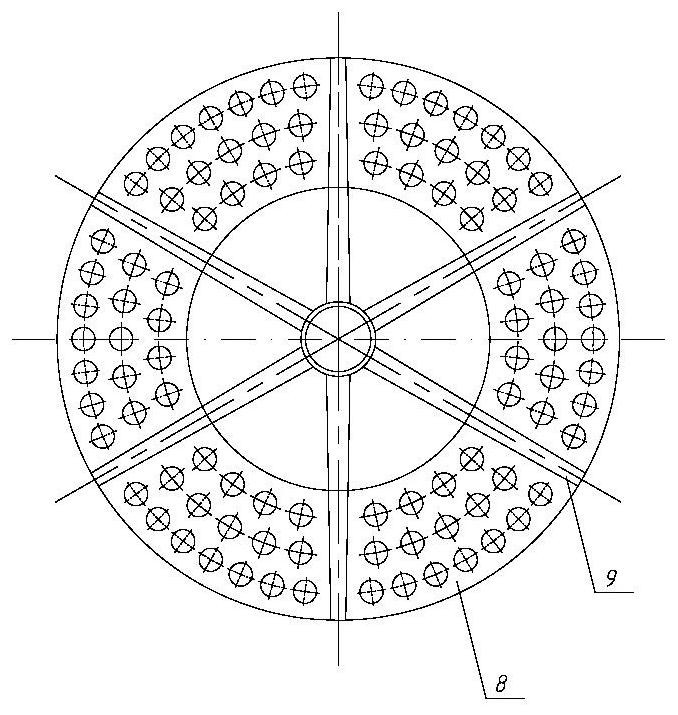

[0084] Such as Figure 5-6 As shown, the first agitator is a cage-type network pan agitator including two circular flower plates 10, several strips 11, several net pans 12, inner short shaft 13 and outer short shaft 14; Parallel to the axial direction of the horizontal cylindrical shell, the two circular flower plates are vertically fixed to the two ends of the slats respectively, and the network disks are vertically fixed on the axial direction of the slats in series, and the circular flower plates Plat...

Embodiment 3

[0086] Embodiment 3 (ring disc stirrer+spiral ring tube stirrer)

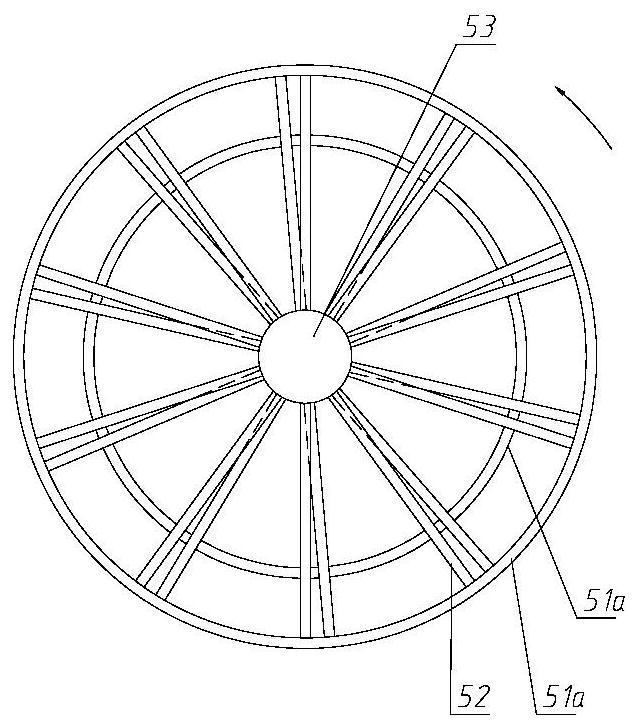

[0087] The difference between this embodiment and embodiment 1 is that the second agitator is a helical loop agitator. Such as Figure 7-9 As shown, the spiral ring tube agitator includes a second rotating shaft 4 and a spiral ring tube 5b axially fixed on the second rotating shaft; It consists of different spirals 51b; the two ends of the second rotating shaft are respectively supported by the rotating shaft sleeve 21 fixed on the discharge side end cover 20 of the cylindrical shell and the sliding bearing seat 16 inside the cylinder. A shaft sleeve 53 is arranged on the second rotating shaft, and the spiral ring is fixed on the shaft sleeve through a plurality of support bars 52 . The length of the spiral ring with a larger diameter is longer than the length of the spiral ring with a smaller diameter, and the number of the spiral rings on the same cross section of the horizontal cylindrical shell gradually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com