Production method for continuously producing high-viscosity polymer

A production method and polymer technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problem that the viscosity of polymers cannot be further improved, increase investment costs and production costs, and affect the final Product quality and other issues, to achieve the effect of easy to form stretch film and sagging film, reduce high temperature residence time, and improve surface renewal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

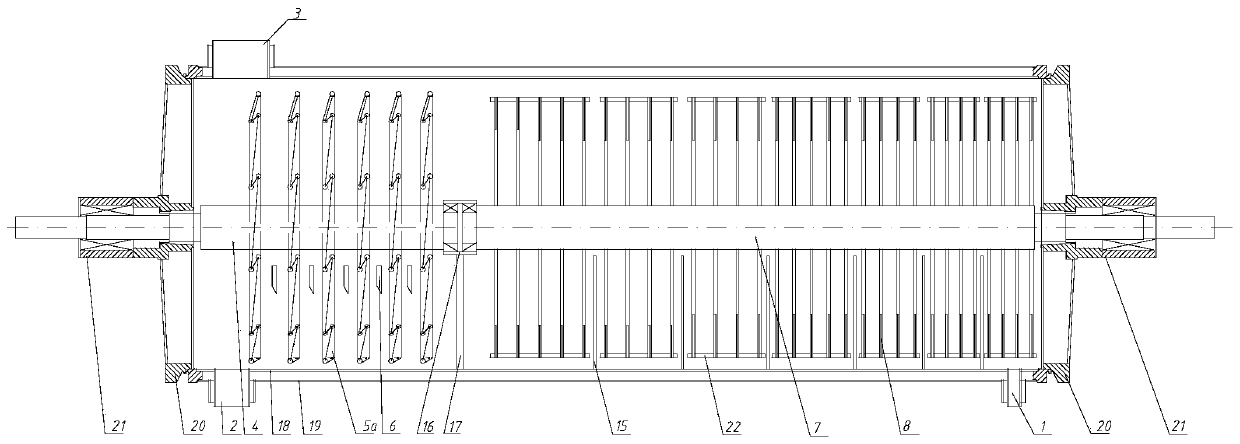

[0086] Embodiment 1 (ring disc stirrer+spiral blade stirrer)

[0087] A production method for continuously producing high-viscosity PET polymers, comprising the following steps: continuously feeding a PET prepolymer melt with a material intrinsic viscosity of 0.25 dL / g into the final polycondensation reactor of the present invention, at a temperature of 275° C. , under the condition of an absolute pressure of 120Pa, the reaction stays for 120min, and is discharged from the discharge port to prepare a high-viscosity PET polymer with an intrinsic viscosity of 0.90dL / g. Wherein in the polycondensation reactor, the prepolymer melt is successively processed by the first agitator and the second agitator with different rotating speeds. The rotational speed range of the first agitator is 5.8 rpm, and the rotational speed range of the second agitator is 3.5 rpm.

[0088] Above-mentioned final polycondensation reactor is a kind of polycondensation reactor of high viscosity polymer, as ...

Embodiment 2

[0094] Embodiment 2 (cage frame type mesh pan stirrer + helical blade type tube pan stirrer)

[0095] A production method for continuous production of high-viscosity PTT polymers, comprising the following steps: continuously feeding a PTT prepolymer melt with a material intrinsic viscosity of 0.30dL / g into a final polycondensation reactor at a temperature of 260°C and an absolute pressure of Under the condition of 100Pa, the reaction stays for 150min and is discharged from the discharge port to prepare a high-viscosity PTT polymer with an intrinsic viscosity of 1.05dL / g. Wherein, in the final polycondensation reactor, the prepolymer melt is successively processed by the first agitator and the second agitator with different rotating speeds. The speed range of the first stirrer was 3.2 rpm, and the speed range of the second stirrer was 2.4 rpm.

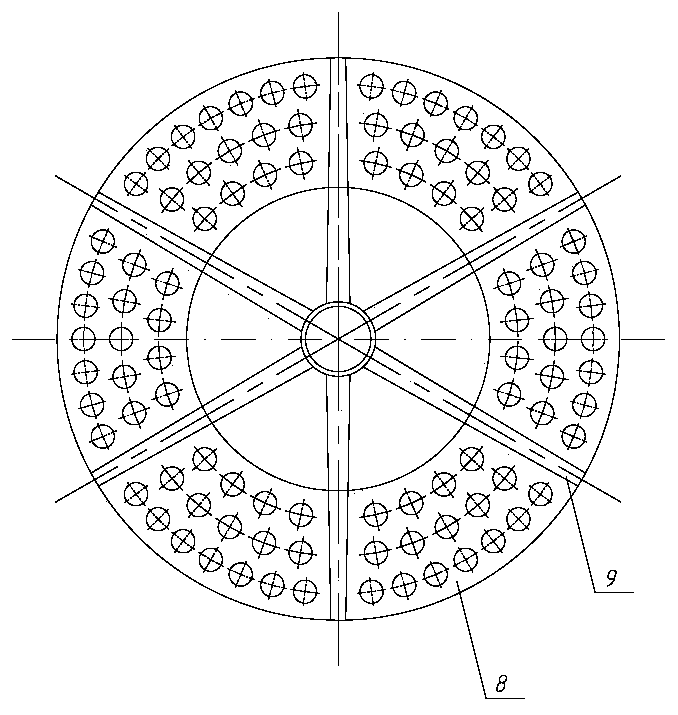

[0096] The difference between the polycondensation reactor of the present embodiment and embodiment 1 is:

[0097] The cross-section...

Embodiment 3

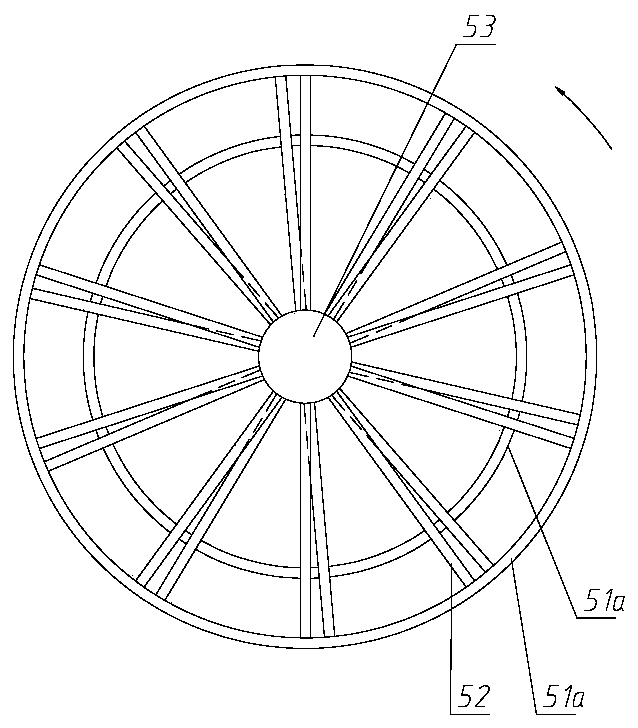

[0100] Embodiment 3 (ring disc stirrer+spiral ring tube stirrer)

[0101] A production method for continuous production of high-viscosity PTT polymers, comprising the following steps: continuously feeding a PTT prepolymer melt with a material intrinsic viscosity of 0.30dL / g into a final polycondensation reactor at a temperature of 260°C and an absolute pressure of Under the condition of 100Pa, the reaction stays for 150min and is discharged from the discharge port to prepare a high-viscosity PTT polymer with an intrinsic viscosity of 1.05dL / g. Wherein, in the final polycondensation reactor, the prepolymer melt is successively processed by the first agitator and the second agitator with different rotating speeds. The speed range of the first stirrer was 5.6 rpm, and the speed range of the second stirrer was 2.1 rpm.

[0102] The difference between the polycondensation reactor of this embodiment and that of Embodiment 1 is that: the second agitator adopts a helical loop agitato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com