Electric spark machining stability and energy consumption state optimization decision-making system and method based on deep learning

A state optimization and processing state technology, applied in the direction of electric processing equipment, manufacturing computing system, metal processing equipment, etc., can solve the problems of low energy utilization rate and high energy consumption in EDM

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0123] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

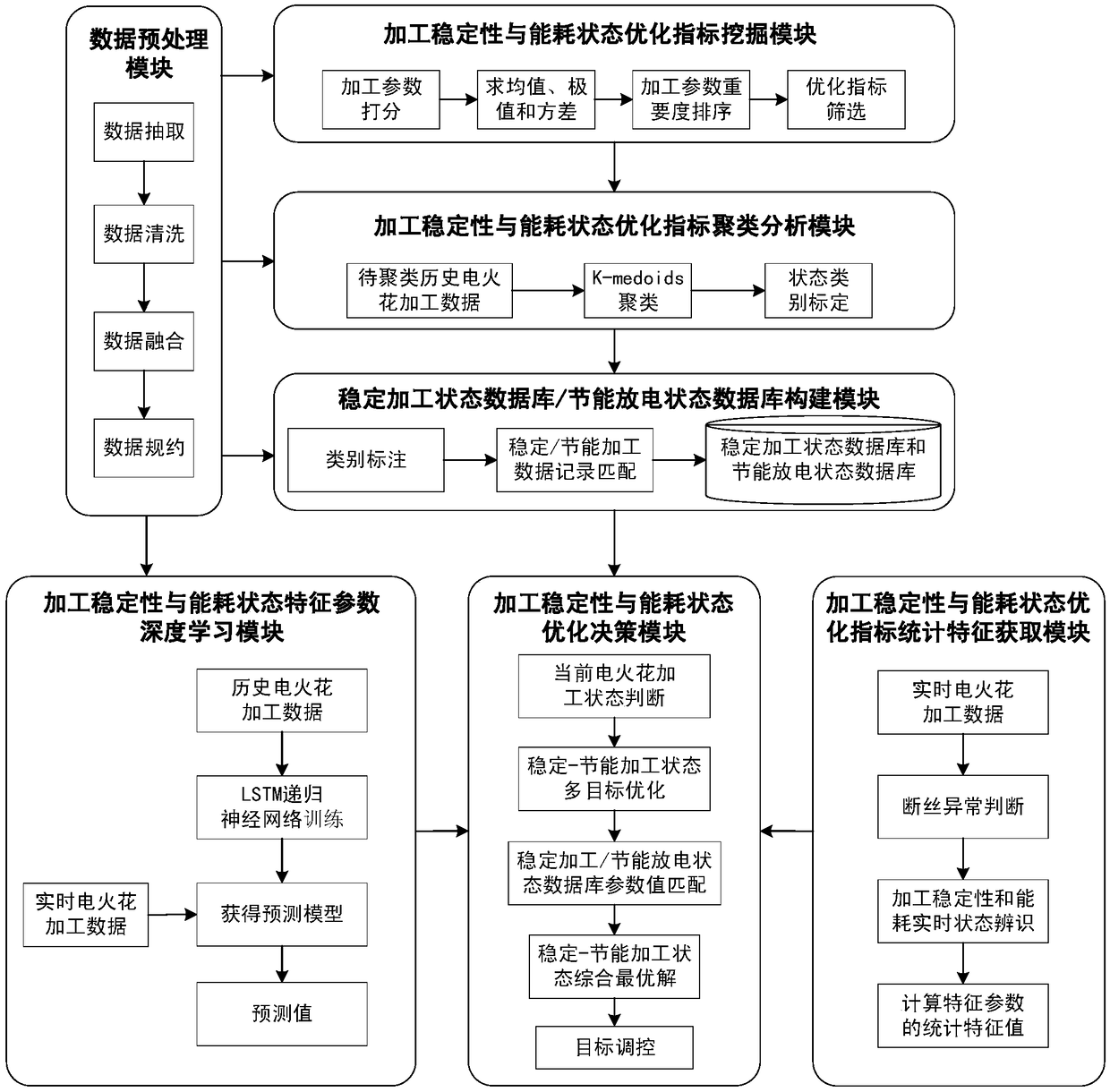

[0124] as attached figure 1 As shown, the function of each module of the EDM stability and energy consumption state optimization decision-making platform based on deep learning and the logical relationship between each module are proposed.

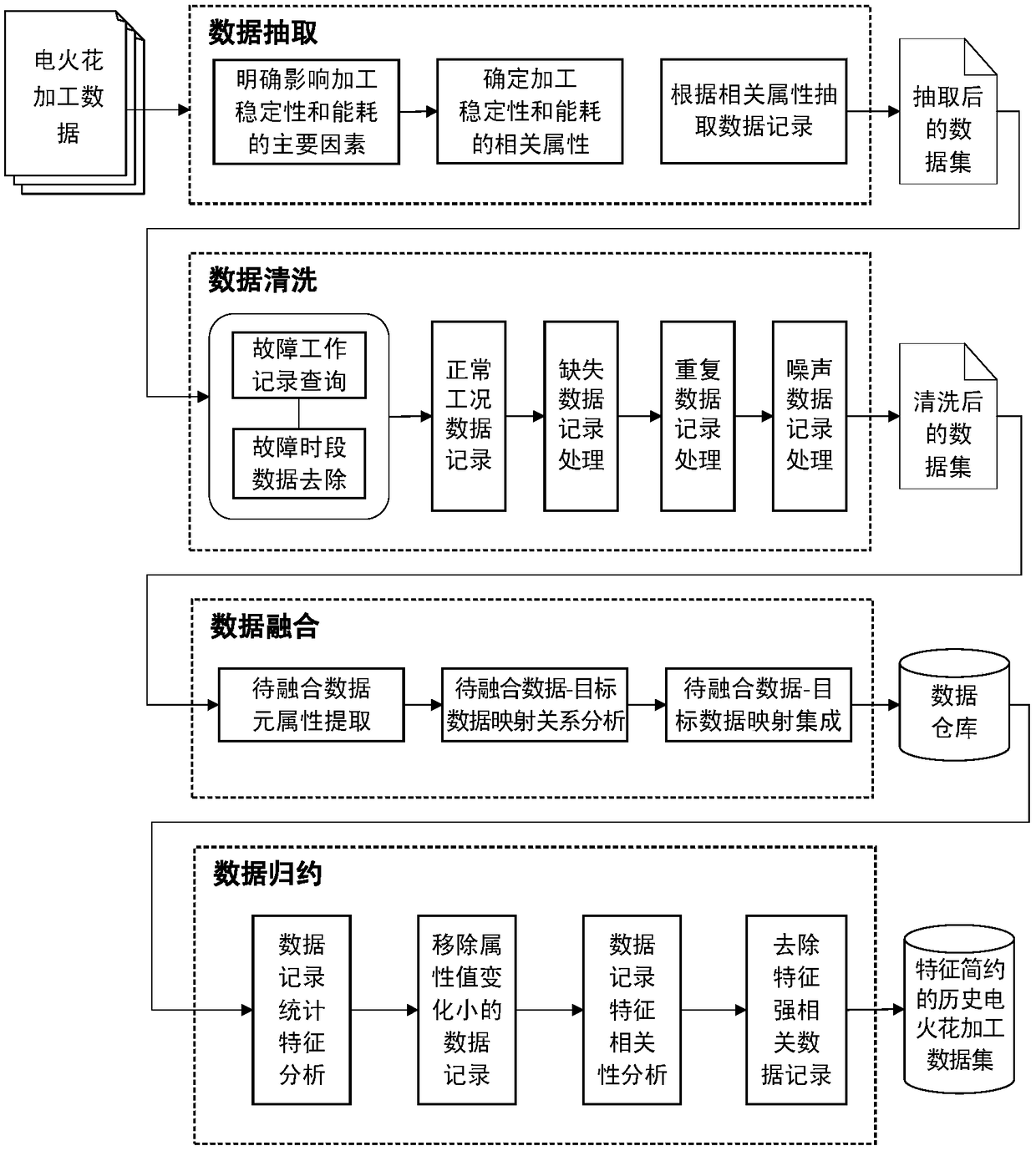

[0125]The data preprocessing module is used to extract, clean, fuse and reduce the EDM data obtained by the electronic control device of the EDM machine tool, and optimize the index mining module, processing stability and energy consumption status for subsequent processing stability and energy consumption. The energy consumption state optimization index cluster analysis module, the stable processing state database and the energy-saving discharge state database construction module, and the processing stability and energy consumption state characteristic parameter deep learning module provide basic historical EDM data;

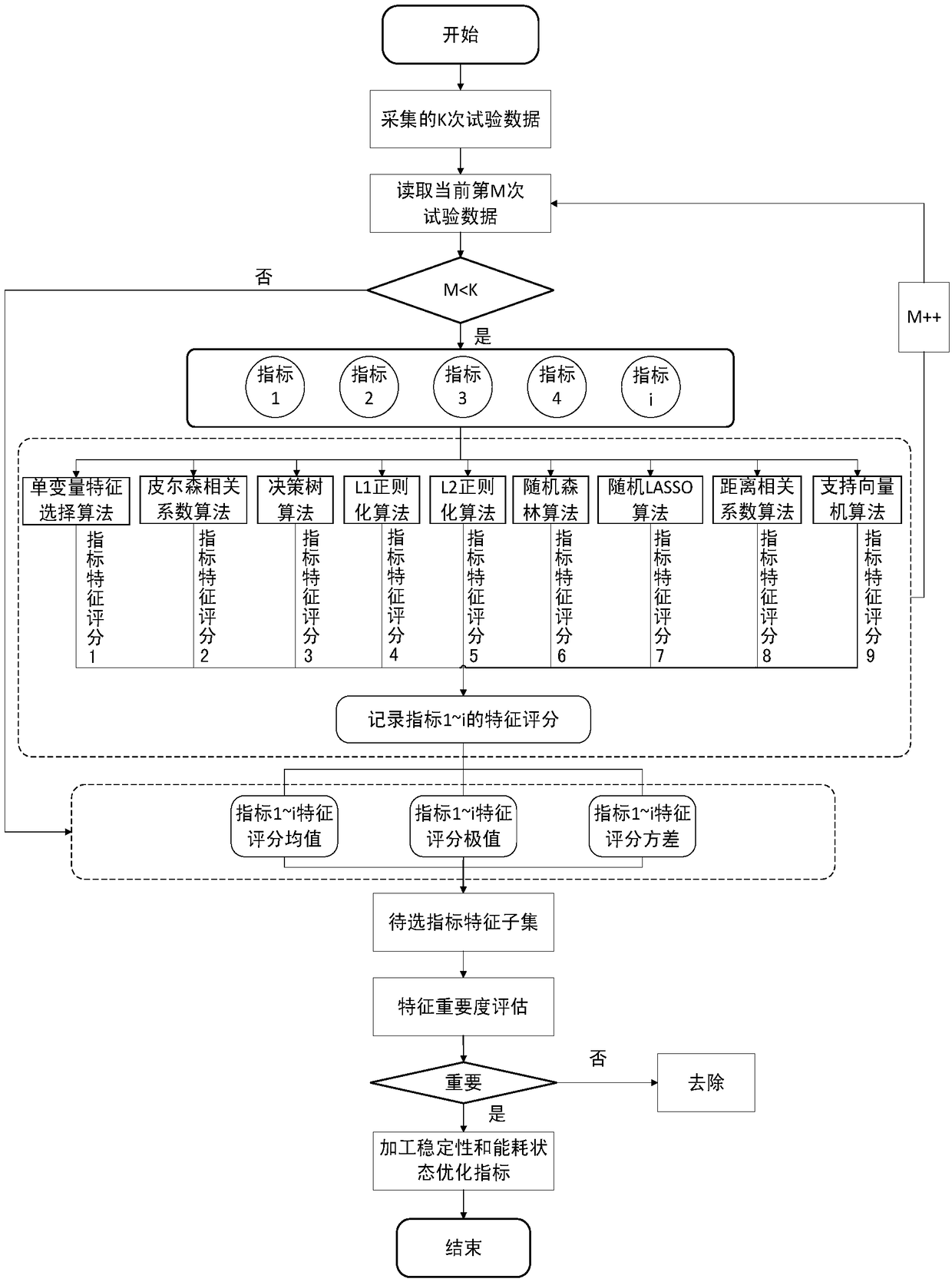

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com