Method and equipment for processing pipeline through plastic oil tank

A technology of a plastic fuel tank and a processing method, which is applied to the substructure and other directions, can solve the problem that the processing efficiency cannot meet the high-efficiency production, etc., and achieve the effects of convenient access and turnover, improved processing accuracy, and improved processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

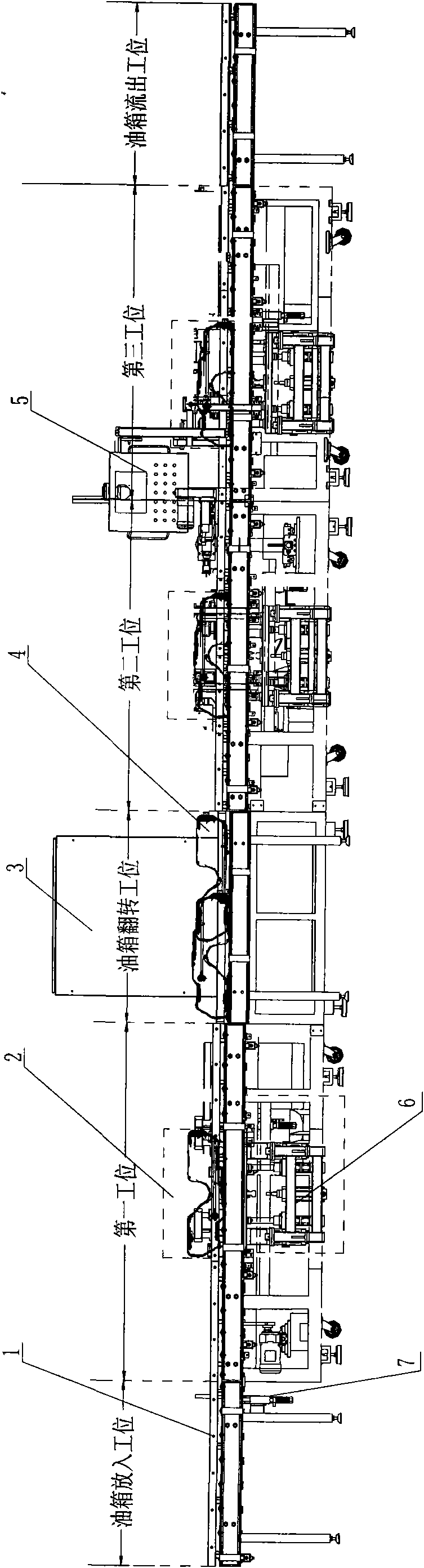

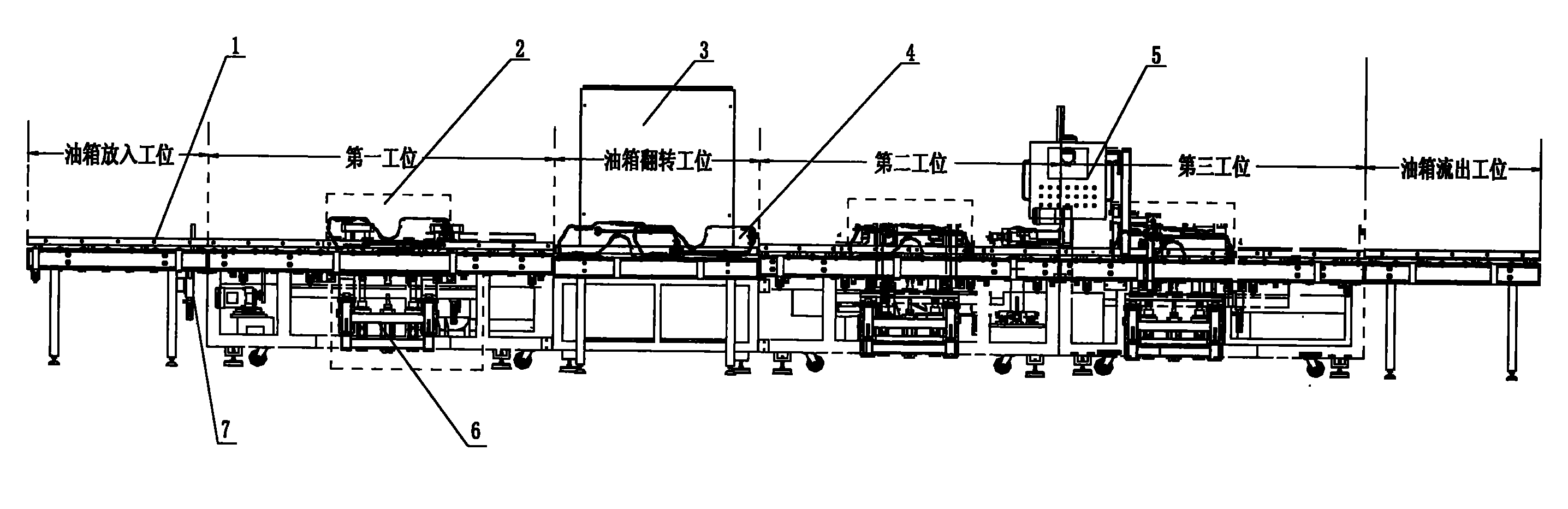

[0031] like figure 1 As shown, the assembly line through-type plastic fuel tank processing equipment of the present invention is divided into five stations, which are respectively the fuel tank putting station, the first station, the fuel tank turning station, the second station, the third station and the fuel tank outflow station bit. Among them, the oil tank putting station is also called the preparation station, and the first to third stations are the oil tank processing stations. An upper positioning mechanism and a station processing equipment 2 are sequentially provided above each processing station, and a lower positioning mechanism 6 is respectively provided below each processing station. Wherein, the lower positioning mechanism 6 can rise or fall, and when it rises, it can hold up the fuel tank 4 and make the fuel tank 4 separate from the drum power assembly line 1 . Under the combined action of the lower positioning mechanism 6 and the upper positioning mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com