Automatic-puncturing terminal crimping tin dipping machine

A technology of piercing terminals and tin-dipping machines, which is applied in the direction of connection, connection connection by deformation, needle tip/slotted plate contact used for penetrating insulated wire/cable core wire, etc., which can solve damage and low efficiency , continuous processing products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

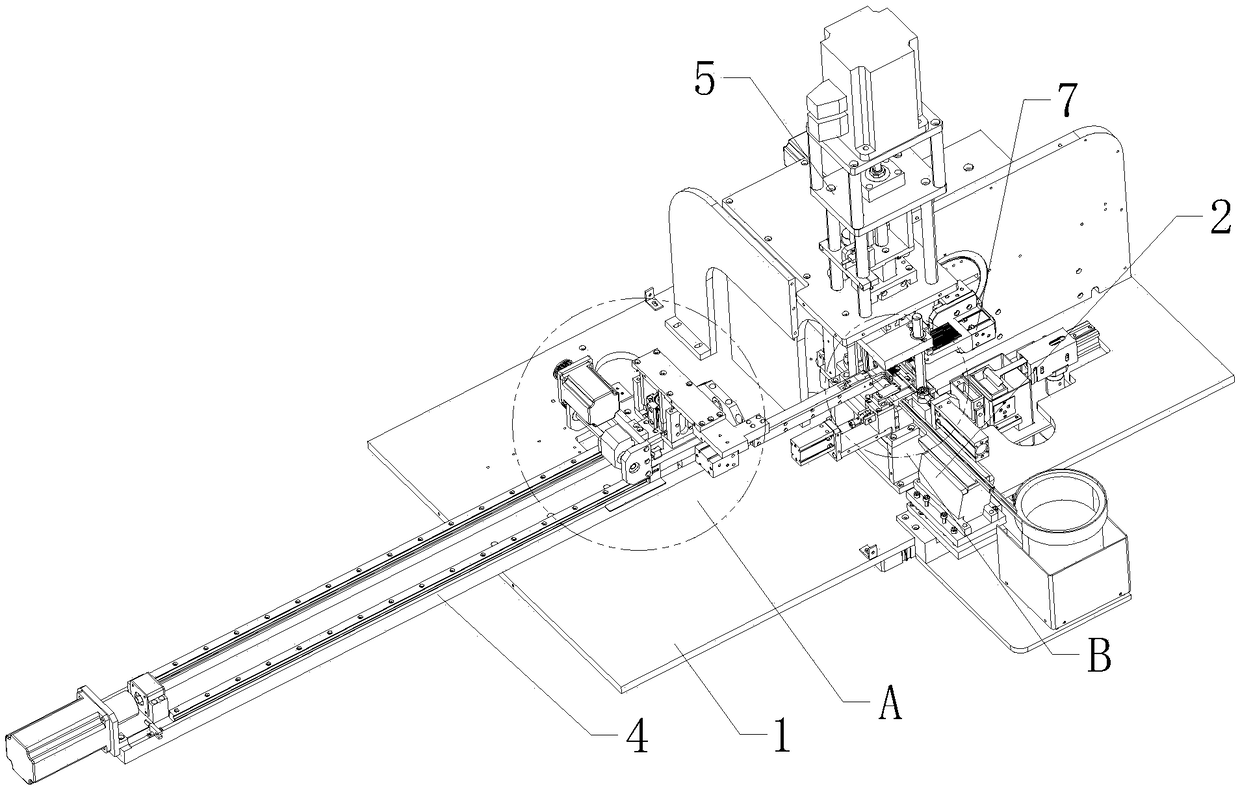

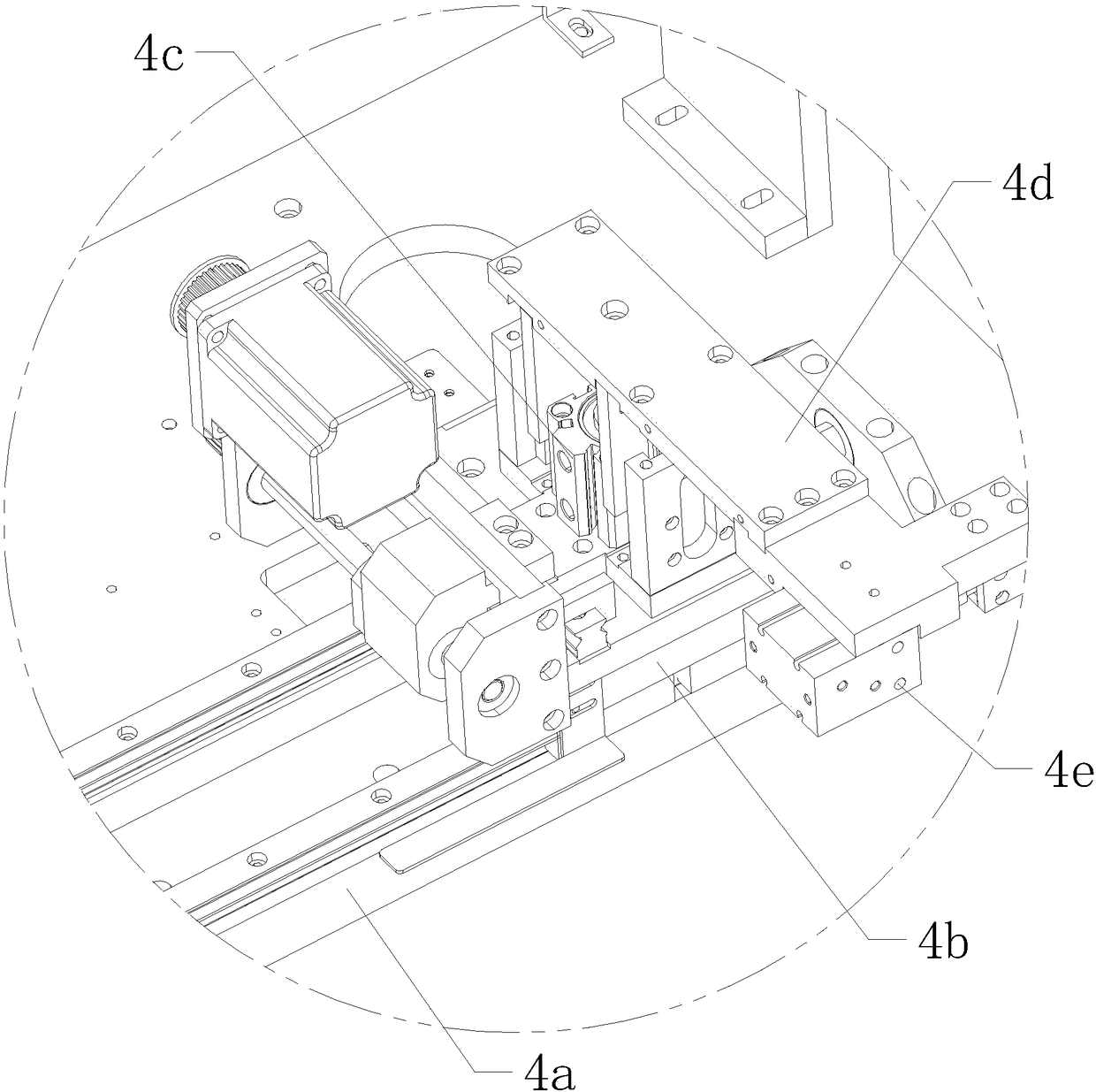

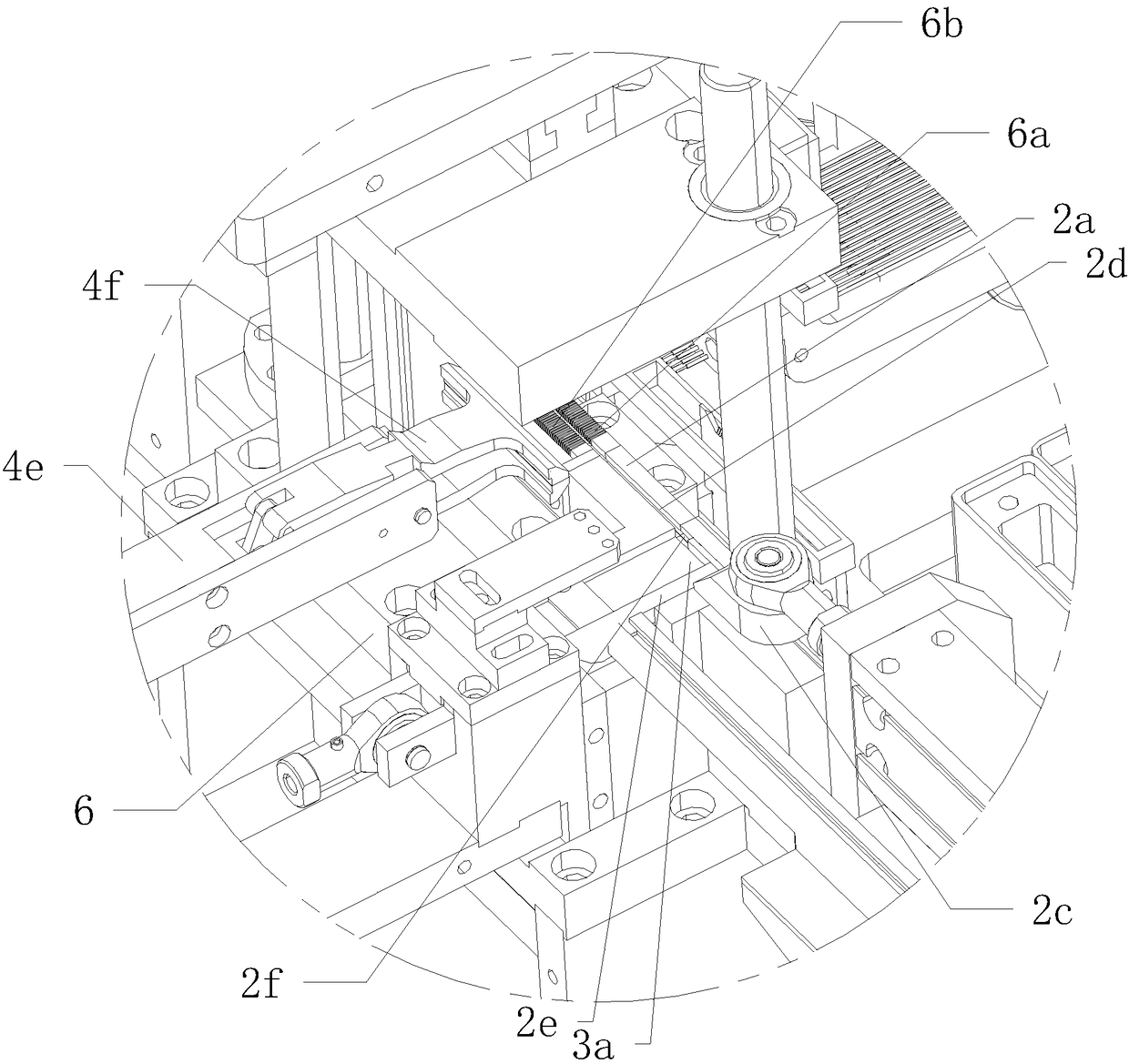

[0031] refer to Figure 1 to Figure 12 The shown automatic piercing type terminal crimping tin dipping machine includes a processing table 1, a terminal transfer device 2 arranged on the front side of the processing table 1, and tin dipping devices 7 arranged symmetrically at the left and right ends of the processing table 1 and clamping materials. Device 4, a crimping device 5 is provided above the processing table 1, the crimping device 5 is located between the tin dipping device 7 and the clamping device 4, a stabilizing block 6 is provided on the processing table 1, and the stabilizing block 6 is located in the crimping device 5 Right below, the top of the stabilizing block 6 is symmetrically equipped with a lower mold cutting knife seat 6a and a lower mold terminal avoiding block 6b, and a container for placing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com