Special flame-retardant nylon material for cable sheaths of new energy vehicles, and preparation method thereof

A flame-retardant nylon, new energy vehicle technology, applied in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of inconvenient procurement, high price, long cycle, etc., to improve processing performance and apparent performance , the effect of improving flexibility and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

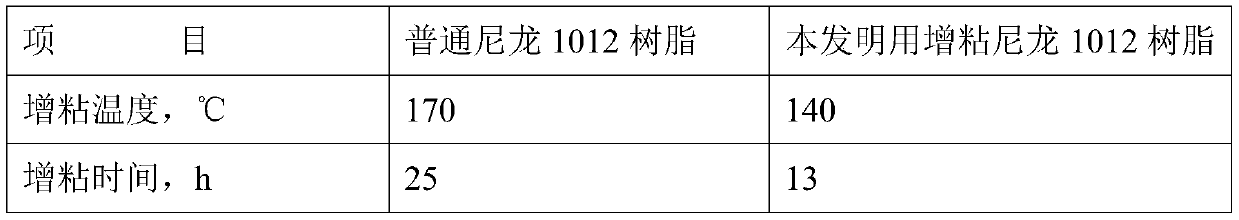

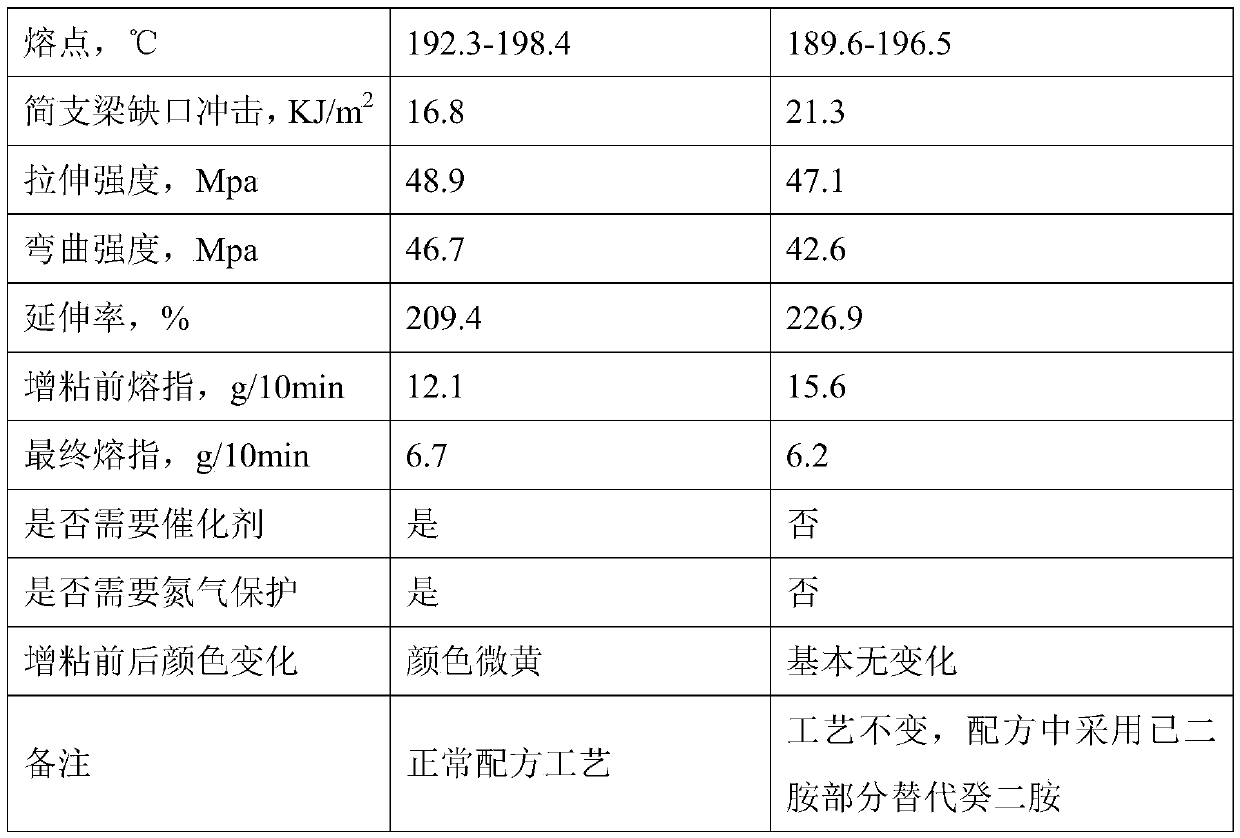

[0023] Preparation of Raw Material Tackifying Nylon 1012 Resin

[0024] Preparation of nylon 1012 resin: Dissolve 1 mol of decanediamine, hexamethylenediamine mixture (wherein the weight ratio of decanediamine and hexamethylenediamine is 97:3) and 1.0mol of dodecane dibasic acid in deionized water, at 75 Stir and mix for 30 minutes at ℃ to carry out neutralization reaction to prepare nylon 1012 salt, and continue to keep warm at 70°C; then add 1012 salt at 70°C, deionized water, and antioxidant (phosphorous acid) into the polymerization kettle, and heat up to 230°C , under the pressure of 1.3MPa (gauge pressure), polymerize for 6 hours, then depressurize to normal pressure, continue to keep warm for 50 minutes, take samples to detect the melt index, if the melt index is less than 16g / 10min, start discharging, otherwise continue to maintain pressure, according to the specific Determine the pressure holding time (about 10-20min) for the condition of the melt finger and take samp...

Embodiment 1

[0038] Then add 70 kg of tackified nylon 1012 resin, 30 kg of nylon 12 elastomer, 8 kg of nitrogen-based flame retardant (German BASF flame retardant MC50), and 0.3 kg of compound lubricant into the high-mixer in turn for 3 minutes. Put the materials for use.

[0039] Extruder setting temperature: feeding section 140°C, melting section 200-220°C, head section 210-230°C, screw speed: 15Hz.

[0040] After the temperature of each section of the relevant extruder reaches the set temperature and the screw can be rotated by hand, after cleaning the equipment with relevant raw materials, add the mixed materials into the extruder for mixing, and the standby head can extrude the material smoothly. When the strips are drawn, carry out traction cooling, air-drying and granulation (drying with a blow dryer, granulation with a granulator).

[0041] Then sieve with a vibrating sieve, dry the material at 80°C, and after the moisture reaches within 0.1%, discharge the material and carry out ...

Embodiment 2

[0043] Add 50 kg of tackified nylon 1012 resin, 50 kg of nylon 12 elastomer, 12 kg of nitrogen-based flame retardant (Doher-6003), and 1 kg of compounded lubricant into the high-mixer in turn for 5 minutes and discharge for later use.

[0044] Extruder setting temperature: feeding section 160°C, melting section 210-230°C, head section 220°C, screw speed: 30Hz.

[0045] Dry the material at 90°C, and after the moisture reaches less than 0.1%, discharge the material and carry out moisture-proof packaging.

[0046] Others are with embodiment 1. The performance index of the product is shown in Table 3 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com