Ultrasonic roll welding anvil base with metal chip scraping and dust removing functions

A metal chip and ultrasonic technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of insufficient installation method and chip processing method of metal ultrasonic rolling welding anvil, improve welding quality and facilitate disassembly. , The effect of convenient position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

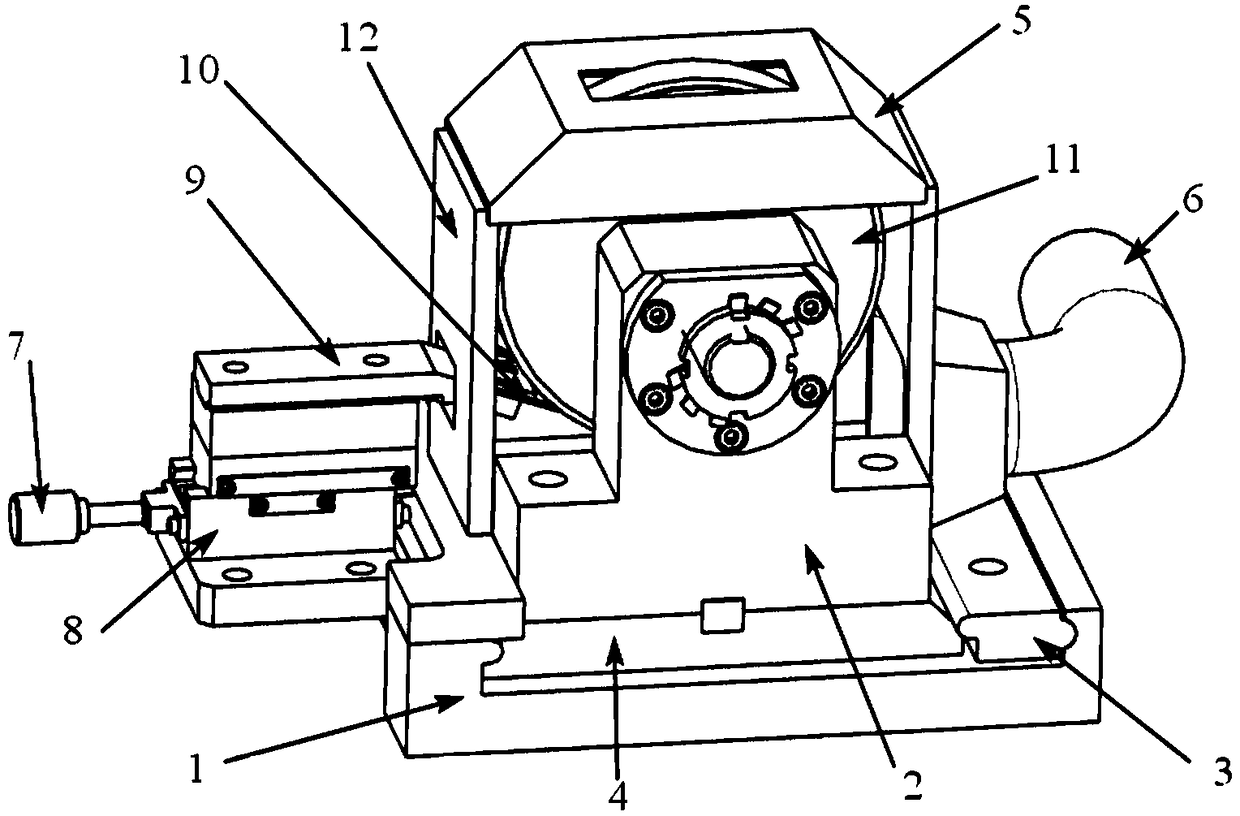

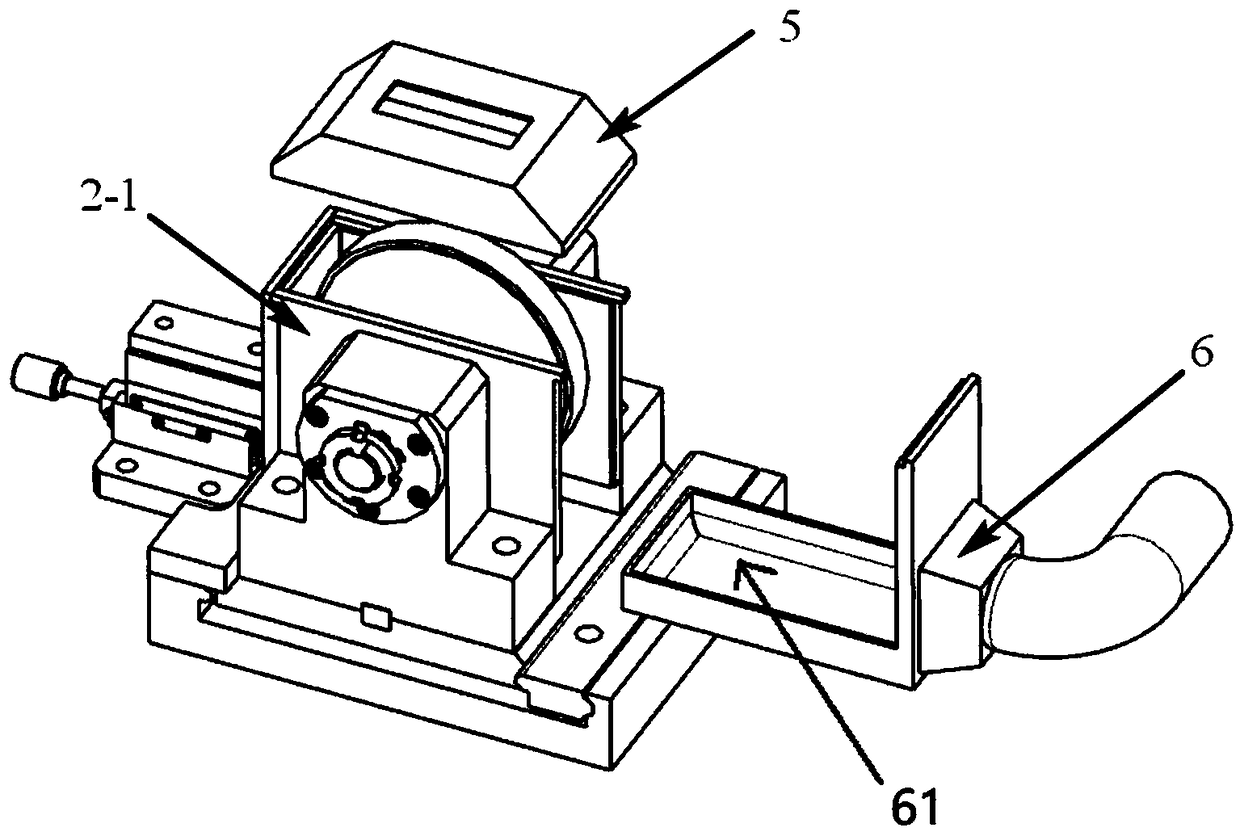

[0020] Figure 1-Figure 2 Shown is an ultrasonic seam welding anvil with the functions of scraping metal debris and dust removal, the ultrasonic seam welding anvil includes a fixed base 1, a dovetail placed on the fixed base 1 and slidably connected with the fixed base 1 The groove bottom plate 4, the pressing plate 3 placed on both sides of the dovetail groove bottom plate 4, the bearing seat 2 placed on the dovetail groove bottom plate 4, the anvil body 11 installed between the bearing seats 2 through bearings, A scraper assembly is provided on one side of the base 1, and the scraper assembly is slidably connected to the base 1. A dust-proof mechanism is provided outside the anvil body 11, and the scraper assembly passes through the dust-proof mechanism and approaches the The anvil body 11; the scraper assembly includes a slider 8, a screw rod 7 placed on the side of the slider 8 away from the base 1, a scraper rod 9 placed on the upper end of the slider 8, placed on the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com